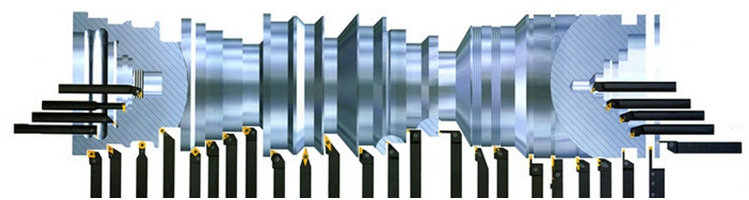

Turning Tools Metal Lathe Cutting Tools Diamond Cutting Tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of cutting tool:

Including external turning tool holders, boring bars, threading holders, grooving holders, cartridge and micro turning tools.

As the first product, our turning cutting tools has the following impassable advantages:

· our turning cutting tools cover a wide application range with a full line-up of ISO cutting tools that produce high quality and high precision cutting tools and parts for all manufacturers’ requirements.

· Main cutting tool’s type include external turning tool holders, boring bars, threading holders, grooving holders, cartridge and micro turning tools.

· All the spare cutting tools are made by ourselves, stable and controllable quality can reduce the wear of the insert and adjustment time.

Application

· Mainly use for turning machine, boring, grooving and threading in NC Lathe.

- Q:What's the difference between a milling cutter and a blade?

- Milling cutter is a rotating cutter with one or more blade teeth for milling. At work, each blade of the knife cuts the amount of the workpiece intermittently. The milling cutter is mainly used in milling machine to process planes, steps, grooves, forming surfaces and cutting off workpieces.

- Q:Lathe tool welding method!! Concrete action steps!! Precautions should be taken!

- To make the handle Find the alloy to be welded You want acetylene and oxygen to ignite Burn the copper strip in the position of welding Sprinkle powder before it is set (a white powder is not good for me) Put the alloy on it. Waiting for him to cool

- Q:The tip of the tool tip

- The tip of the blade determines the smooth finish of the cutting workpiece, and the tip of the blade has different functions, and it is necessary to grind a small circular arc to the tip of the blade.

- Q:What is the best vehicle for threading

- According to the analysis; The toughness of the material is not very high hardness materials, the main cutting edge on the cutting dosage is too large to the chip breaker of cutting not, this case can be on the main cutting edge grinding out R1.5 deep 1 chip breaker groove.

- Q:How to install the external turning tool

- Steps: The tip of the knife is about one to two millimeters above the workpiece. The cutter should not be perpendicular to the workpiece, the resistance is large. 3, props slightly backwards to reduce resistance. 4, the less the knife stick, the better the blade should not be too weak, at least with two screws. Supplement: About 90 degrees f: Inner 8: the slot of the former small size, groove deep 1 to 2mm. Outer 8: the slot of the former big, groove deep 1 to 2 millimeter.

- Q:The lathe tool is not moving when the thread of the CNC lathe thread

- This is the thread head signal missing from the main shaft encoder, and the thread knife is at the starting point. The knife occasionally moves because the signal line is not in contact. You can twist the attachment of the main shaft encoder, move it to see if there is any change, or see if there is a broken line, find fault here.

- Q:Can the welding tool be welded with 2.5 copper wire

- S221 tin brass wire, copper wire welding is 2.5 and 3.0 can choose according to need to use, brass is about 890 ℃, melting point, gas welding, brazing carbide tool bit are available, and can also be brazing of copper, steel, cast iron, etc

- Q:What is the advantage of a convertible car knife compared to a regular one

- Improve the cutting performance, improve the efficiency and stability of the mechanical clamps, extend the life of the cutter, save the blade, the cutting time, save the hilt

- Q:What kind of car knife works well?

- Such questions are too wide to be answered by 3,000 points.I hope my answer will help you.

- Q:Make a simple stationary lathe tool for diy lathe

- The guideway is the track that is used to support and guide the parts of the machine on a certain trajectory. The accuracy of the track and the accuracy of the movement directly affect the machining accuracy of the machine. There are slide guide, roller guide and static pressure guide. The shape of the guideway is mainly V, rectangle, dovetail, cylindrical and planar

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Turning Tools Metal Lathe Cutting Tools Diamond Cutting Tool

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords