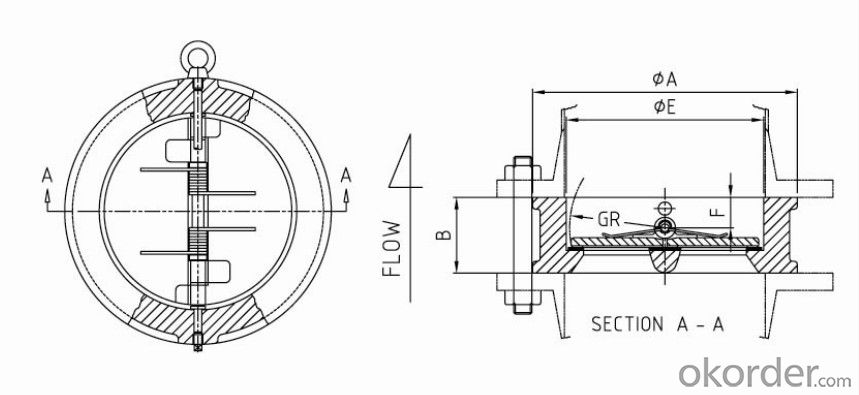

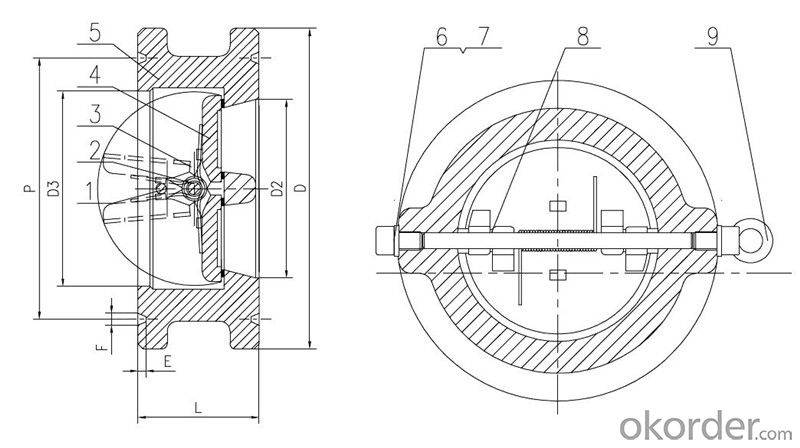

Swing Check Valve Wafer Type Double Disc DN 650 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q:my check engine light tells me that i need an egr valve, if i install one will that cut the light off????

- Possibly. If you don't go out then you need to have someone hook up a code reader and clear the SES light.

- Q:To control a double solenoid valve, what do you recommend to use in my PLC program .... Do you recommend to use the SetReset coils or to use the normal coils?

- You may want to check with the company that manufactured the valve - that would be your most likely source.

- Q:okay, where the dome is on the head (where the flat part of the valves sit) the intake is uneven and the air+gas mixture escapes threw the open space when the piston goes up into the compression stage, and ignites shooting flames out of my exhaust port. the space is small but u can see light threw it when the valve sits there. Would some kind of Liquid metal work? or gas+heat resistant epoxy work to take the place of the missing space? I would file it but that would not be precise and time consuming, and i would buy a new head for $150, but the dealer doubles that price! and no way am i paying $300 for a new head. any comments would be well appreciated!

- take bike to dealer and get it fixed right.

- Q:I just fixed a clog in my bathroom sink by taking off the p-trap. I had turned off the water valve beforehand, and when I was done I turned it back on. After this, all that came out of the faucet was a trickle. Turning the valve in the off position does not stop the trickle. When I first turned the valve off before taking off the pipe, the valve was not turned all the way left or right. It was in the middle, but the water flowed fine. When I turned the valve all the way to the right, the water shut off at the faucet. My apartment is pretty old. Is this valve most likely broken?

- Could be a 3-way valve. Try putting it back in the middle. If that doesn't work, it probably broke.

- Q:I have a training I will be attending on Valve actuator and subsequently an exam. I need fundamental knowledge of ROV. What are the types of ROV. The Maintenance Of ROV ? and the different Type of ROV actuators

- The term remote operated valve is slightly misleading, as it really means remotely controlled valve. Normally the valve actuator is mounted directly on the valve body so that it can open and close the valve. The majority of valves are either rotary ball or sliding gate type. Valve actuators can be operated by electrical methods, pneumatic or hydraulic, or by a combination. The most common types of actuator for industrial use are motorised electrical and pneumatic. Motorised valves will have a reversible motor for opening and closing, whilst pneumatic types will have a double acting cylinder with a 5 port 2 position or 3 position control valve. The control contactors and valves would be located in a control room, possibly controlled by a PLC or similar automation controller. In most cases position feedback will be supplied from the valve by means of limit switches to indicate its position, and in the case of motorised actuators, the running current can be monitored as an indicator of valve condition. If a pneumatic valve is jammed, the actuator will simply stall without damage, but for electrical actuators some form of overload protection is required to prevent excessive current load and overheating. The majority of industrial valves require little maintenance, but regular inspection for security, electrical connections, gland sealing etc should be scheduled at intervals suitable for the working environment.

- Q:How come my boiler supply valve isnt letting water into my boiler, i have a cold water supply hooked up to it with the valve on i have tested the copper pipe goin into it and water flows into it, but when It reaches the valve it stops. I understand that it my have a backflow preventer in it and I am wondering if that could be malfunctioning. The hole you see on the front is where my expansion tank screws in. Also where could I get a new Valve. Thanks.http://img149.imageshack.us/i/boilerfillvalve.jpg/

- I work on antique steam boilers and engines for a hobby and if your supply valve isn't letting feedwater into the boiler, I'm going to tell you right now that you potentially have a VERY dangerous situation on your hands. Until you get this issue resolved, I would recommend that you not steam this boiler up under any circumstances, unless you have a backup feedwater delivery system that is working correctly. Many people don't know this, but a low water condition in a boiler under steam is essentially a ticking time bomb and can result in a fatal explosion. As to what may be causing it, I would say it's possibly one of two things: 1.) The check valve has been installed backwards and the flow of water is basically pushing it shut. 2.) The check valve is installed correctly, but is frozen shut due to corrosion and scale. Either way, I would have a certified boiler inspector come out and take a look at it; he can probably tell you more than I can.

- Q:Hi. I am planning to install new kitchen faucet and noticed that there are two shut off valves under the sink. One of them is badly rusted and needs to be replaced. I noticed that it is connected to three pipes (one of which is kitchen faucet). The other is clearly water coming in. What is the third one connected to wall? Also how should I go about replacing this? Anything that I should be careful of?

- it looks like a 1/2 inch galvanized pipe out of the wall, and the valve is screwed on to it. kinda hard to see the back side of the valve and pipe. it could be a 1/2 inch copper pipe and the valve could be a compression type. anyway, you will have to cut the water off unless this is the hot line in and if so you can cut the water off at the water heater. its probably a cold line in and obviously you cant take the valve off without cutting off the main supply line some where. take off the two small lines and don't move them around to much, they are compression fittings so just reattach them to the new valve. then unscrew the valve, you may have to hold the incoming pipe but just try the valve first. take the valve to a plumbing supply, Lowe's, or home depot and get one just like it. if one place doesn't have it go to another and find the same valve. if it screws on get a small tube of pipe dope to coat the threads. if you anticipate problems get a 1/2 inch galvanized cap [if that is the pipe you have coming out of the wall] so you can plug the pipe and cut the water back on temporally. this is general info so you will have to deal with your special situation. good luck.

- Q:so, im a day away from getting a 2002 748 and im super excited, iv always wanted a ducati, and i cant wait to have one of my own. i understand that ducks have a reputation of breaking and im prepared for it. I also understand the valves need to be adjusted every 50-100 feet :P all kidding aside i know every 6k miles they need to be adjusted. i dont know however how much it costs to have the valves adjusted. im sure it varys from shop to shop but a ball park quote would be really helpful just so its not a kick in the gut when i take it in for the first time. thanks

- believe it or not a desmodromic valve adjustment takes like 8 hours.So its kinda costly to do that job.

- Q:I have presta valves on my mountain bike now and only Presta valves can fit through the hole in the rim where the valve goes. If i want to start using Shrader valve tubes, because they are way more common and i can get them at Walmart, is it ok if i bore out the hole in my rim in order to get the Shrader valve to fit

- Yes you can. Many people have done so. Make sure you file the hole after drilling so you will not have any burrs. BTW most tubes come from China so if you want to put in walmart specials or from a reputable bike shop it will do the job. If you want to put presta valves again, then you can buy a grommet that reduces the hole size. If you have an expensive bike and want to keep it original, then I advise not to drill

- Q:What is the function of valves between atrium and ventricle in the heart?thanks

- the atrioventricular valves (AV valves) separates the atria from the ventricles. the AV valves perform a very important function in the heart by maintaining the blood flow in one direction. they are subjected to tremendous strain during every heart beat, and are uniquely designed to withstand this strain through a person’s lifetime. the right AV valves is called the tricuspid valve. the left AV valve is called the mitral valve. the opening and closing of the AV valves is dependent on pressure differences between the atria and ventricles. when the ventricles relax, atrial pressure exceeds ventricular pressure, the AV valves are pushed open and blood flows into the ventricles. however, when the ventricles contract, ventricular pressure exceeds atrial pressure causing the AV valves to snap shut. :)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 650 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords