Square Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Square Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel in Hot Sale

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel Square Steel Billet

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

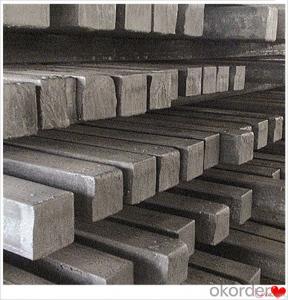

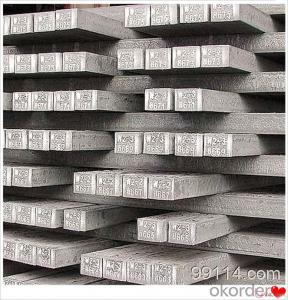

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q:What are the different types of surface defect detection equipment for steel billets?

- There are several types of surface defect detection equipment for steel billets, including ultrasonic testing (UT), magnetic particle inspection (MPI), visual inspection, eddy current testing, and automated optical inspection (AOI). Each of these methods has its own advantages and limitations when it comes to detecting and evaluating surface defects in steel billets.

- Q:Can steel billets be used in the production of bicycles?

- Yes, steel billets can be used in the production of bicycles. Steel is a commonly used material in bicycle manufacturing due to its strength, durability, and affordability. Steel billets can be shaped and manipulated to form various bicycle components such as frames, forks, and handlebars.

- Q:What are the different types of surface finish defects found in steel billets?

- There are several types of surface finish defects that can be found in steel billets. These defects can occur during the manufacturing process or as a result of handling and transportation. Some common types of surface finish defects in steel billets include: 1. Scale: Scale is a type of oxide layer that forms on the surface of steel billets during the heating and rolling process. It appears as a rough, flaky layer that can vary in thickness. Scale can be removed through various surface cleaning methods. 2. Pitting: Pitting is the formation of small, localized depressions or craters on the surface of the steel billet. It can be caused by various factors such as corrosion, improper handling, or contamination during processing. Pitting can weaken the steel and compromise its integrity. 3. Scratches: Scratches are visible marks or lines on the surface of the steel billet. They can occur during handling, transportation, or processing. Scratches can be superficial or deep, depending on the severity. Deep scratches may require further inspection or surface treatment. 4. Roll marks: Roll marks are impressions or patterns left on the surface of the steel billet by the rolling process. These marks can be caused by improper alignment or wear and tear of the rolling equipment. Roll marks can affect the aesthetic appearance of the billet but generally do not impact its structural integrity. 5. Lamination: Lamination is the separation of layers or flakes within the steel billet. It can be caused by inadequate bonding during the manufacturing process or as a result of excessive rolling. Lamination can weaken the steel and compromise its performance. 6. Decarburization: Decarburization is the loss of carbon from the surface of the steel billet. It occurs when the billet is exposed to high temperatures or oxidizing environments. Decarburization can lead to reduced hardness and strength of the steel. 7. Surface irregularities: Surface irregularities refer to any distortion or unevenness on the surface of the steel billet. These can include dents, bulges, or uneven textures. Surface irregularities can be caused by various factors such as improper handling, machining, or defects in the manufacturing process. It is important to note that these surface finish defects can vary in severity and impact on the steel billet. Some defects may be cosmetic and have minimal effect on the performance of the steel, while others may require further inspection or treatment to ensure the structural integrity of the billet.

- Q:What are the specifications for stainless steel billets used in the marine industry?

- The specifications for stainless steel billets used in the marine industry typically include a specific grade of stainless steel, such as 316 or 316L, which offers excellent corrosion resistance in marine environments. These billets are often required to meet certain standards, such as ASTM A276 or ASTM A484, which outline the chemical composition, mechanical properties, and dimensional tolerances for stainless steel products. Additionally, the billets may need to undergo specific heat treatment processes, such as annealing or solution treatment, to ensure optimal strength and corrosion resistance.

- Q:What are the different types of cutting processes used for shaping steel billets?

- There are several different types of cutting processes used for shaping steel billets. These processes include: 1. Bandsaw cutting: Bandsaw cutting is a widely used method for cutting steel billets. It involves using a continuous band of toothed metal blade to cut through the billet. Bandsaws are known for their ability to cut through thick sections of steel quickly and accurately. 2. Abrasive cutting: Abrasive cutting involves using an abrasive wheel or disc to cut through the steel billet. This method is commonly used for cutting smaller billets or for cutting shapes and contours into the billet. Abrasive cutting is known for its versatility and ability to produce smooth and precise cuts. 3. Plasma cutting: Plasma cutting is a thermal cutting process that uses a high-velocity jet of ionized gas to melt and remove the steel from the billet. This method is often used for cutting thick sections of steel or for cutting intricate shapes. Plasma cutting is known for its speed and ability to produce clean cuts. 4. Waterjet cutting: Waterjet cutting is a process that uses a high-pressure jet of water to cut through the steel billet. In some cases, abrasive particles may be added to the water to enhance the cutting ability. Waterjet cutting is known for its ability to cut through thick sections of steel without creating heat-affected zones or distortion. 5. Laser cutting: Laser cutting involves using a high-powered laser beam to melt and vaporize the steel billet. The laser beam is guided by computer controls to cut the desired shape. Laser cutting is known for its precision and ability to cut intricate shapes with minimal distortion. These are just a few examples of the different types of cutting processes used for shaping steel billets. Each process has its own advantages and is chosen based on factors such as the size of the billet, the desired shape, and the required accuracy.

- Q:What are the different types of steel billet manipulation equipment?

- There are several types of steel billet manipulation equipment, including billet lifting devices, billet transfer cars, billet rotating equipment, and billet storage racks.

- Q:What are the main factors affecting the machinability of alloy steel billets?

- The machinability of alloy steel billets is influenced by several key factors. Firstly, the alloy composition of the steel plays a significant role. Different alloying elements, such as chromium, nickel, molybdenum, and vanadium, can affect the machinability of the steel. Elements that form hard carbides, such as chromium and molybdenum, tend to decrease machinability, while elements that promote the formation of softer carbides, such as nickel and vanadium, can enhance machinability. Secondly, the heat treatment of the alloy steel billets can greatly impact machinability. Heat treatment processes like annealing, normalizing, or quenching and tempering can alter the microstructure and hardness of the steel. Proper heat treatment can improve machinability by reducing hardness and increasing toughness, while improper heat treatment can result in increased hardness and decreased machinability. Thirdly, the presence of impurities and inclusions in the alloy steel billets can affect machinability. Inclusions, such as sulfides, oxides, and non-metallic particles, can cause tool wear and chip breakability issues during machining. Therefore, the cleanliness and purity of the alloy steel billets are crucial factors in determining machinability. Furthermore, the mechanical properties of the alloy steel, such as hardness, strength, and ductility, can influence machinability. Higher hardness and strength levels can make machining more challenging, while increased ductility and toughness can improve machinability. Lastly, the cutting conditions and machining parameters, such as cutting speed, feed rate, depth of cut, and tool material, also impact machinability. Optimal cutting conditions should be selected based on the specific alloy steel composition and desired machinability. Adequate cooling and lubrication during machining are also essential to reduce friction and heat, preventing tool wear and improving machinability. In conclusion, the machinability of alloy steel billets is influenced by factors such as alloy composition, heat treatment, impurities and inclusions, mechanical properties, and cutting conditions. Proper consideration of these factors can help optimize the machinability of alloy steel and ensure efficient and effective machining processes.

- Q:Billet heating furnace prices?

- Look at the video case, you can consult the advisory.

- Q:What are the dimensions of a typical steel billet?

- The dimensions of a typical steel billet can vary depending on its intended use and the specific manufacturing process. However, generally speaking, steel billets usually have a rectangular shape with widths ranging from 100mm to 300mm, heights ranging from 100mm to 400mm, and lengths ranging from 6m to 12m. These dimensions allow for easy handling and transportation, as well as flexibility in shaping and forming the steel billet into various end products like bars, rods, or sheets. It's worth noting that these dimensions are not set in stone and can be tailored to meet the specific requirements of the production process or the customer's preferences.

- Q:What is the maximum length of a steel billet?

- The length of a steel billet can differ based on multiple factors like the manufacturing process, equipment capabilities, and specific industry demands. Typically, steel billets can vary in length from a few inches to several meters. Nevertheless, it is crucial to acknowledge that longer billets pose more difficulties in their production and handling due to their heavier weight and potential for distortion. Hence, determining the maximum length of a steel billet is usually based on practical considerations and operational constraints within the steel industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Square Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords