Heat Resistant Borosilicate Glass 3.3 used for Projector lens

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description:

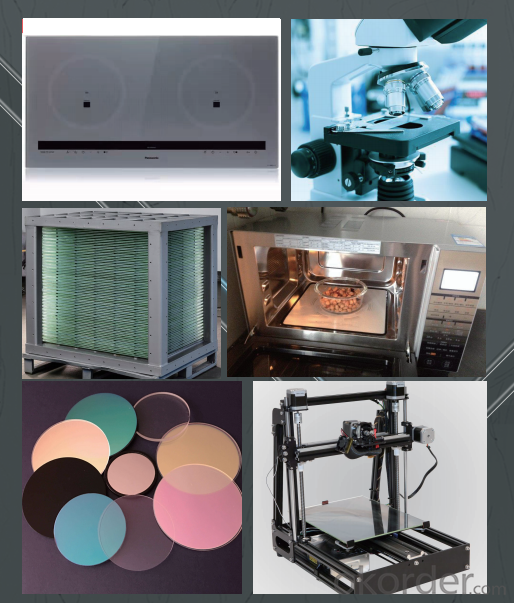

Borosilicate 3.3 serves as a material of truly functional and wide applications:

1). Household electrical appliance (panel for oven and fireplace, microwave tray etc.);

2). Environmental engineering and chemical engineering (Lining layer of repellence, autoclave of chemical reaction and safety

spectacles);

3). Lighting (spotlight and protective glass for jumbo power of floodlight);

4). Power regeneration by solar energy (solar cell base plate);

5). Fine instruments (optical filter);

6). Semi-conductor technology (LCD disc, display glass);

7). Iatrology and bio-engineering;

8). Safety protection (bullet proof glass)

Name | Borosilicate Glass 3.3 |

shape | can make as customer’s request |

Glass Type | Heat resistant Glass |

place of origin | China |

Structure | solid |

Packing | Meet customer's personal requirement |

Color | clear |

Size | 600*800 2200*1650 2440*1830 3300*2140 3660*2140 3660*2440 |

Packing | Wooden box |

Application | Projector lens |

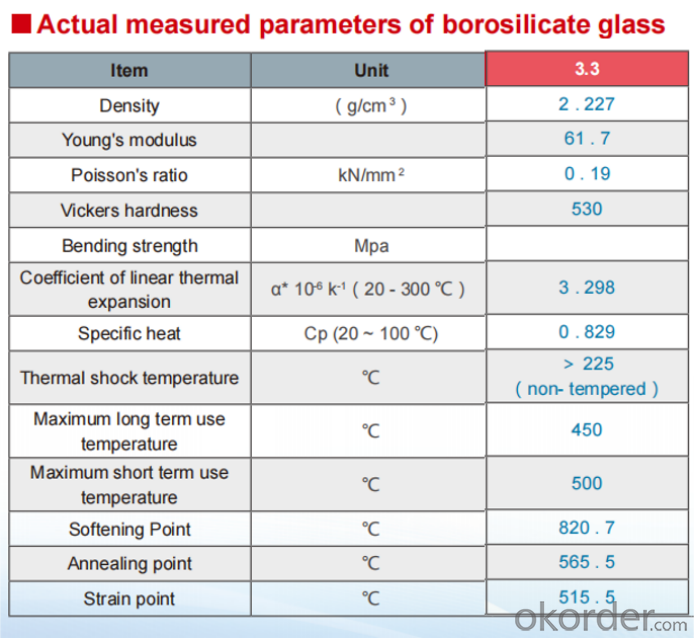

2. Actual measured parameters of Borosilicate Glass:

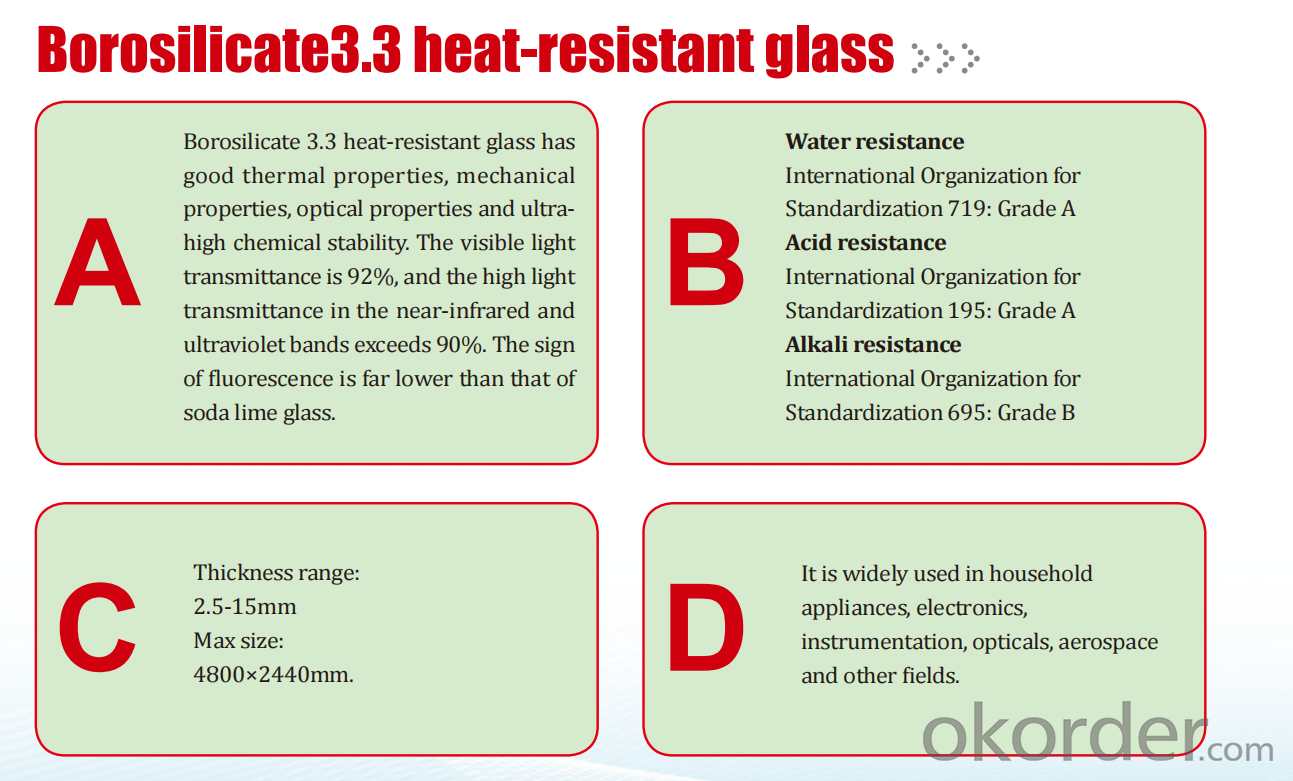

3. Main features:

1. Great heat resistance performance, stable chemical properties

high strength;

2. High light transmittance;

2. High light transmittance;

3. Super acid and alkali resistant;

4. Wide optical applications.

4. Advantage:

Because of the ionic bond, it has good thermal properties, mechanical properties and chemical stability, such as low expansion coefficient, high softening temperature, high strength, low density, and not easy to mold and fog.

CNBM’s largest Size: 4800X2440mm

5. Application Area:

Can be used in fireproof curtain walls, partition walls, platforms, day lighting roofs, smoke-proof vertical walls, railings, doors and windows, elevator shafts, rail transit platform screen doors, rail locomotive doors and windows and other fields. Equipped with water spray, it can be used to replace Class A insulation type fireproof glass system, which can be widely used in building atrium, pedestrian street fireproof glass and building fireproof partition.

More Applications:

l The scope of application:

a) Indoor heating/The windows panel heaters

b) Cover glass heating radiator

c) Reflecting cupand High performance pan light lamp cover

d) Infrared dryer cover

e) Projector protection cover

f) UV shield

g) Barbecue machine panel

6. Process:

7. Packing and Shipping:

All the glass will pack in strong export plywood crates, and load in container strong firmly, to make sure safety delivery.

8. Test Report:

9. Company Brief:

10. FAQ:

Q1:What’s your MOQ?

A: Generally, there is 2 tons for MOQ , CNBM will give you more discount if quantity more.

Q2:Can you send me some samples to check your quality?

A:Sure, CNBM Glass could send the free samples (except special deep processing glass) for you any time. we will refund the courier charge for you once we start business.

Q3:What's the fast production time you can do?

A: It depends on the quantity of building glass you need. Normally it takes 15-45 days after drawing confirmed.

Q4:How can you make sure the glass won't broken during transportation?

A: For all the glass from our factory,we will pack them into strong export plywood crates and load the crates into container with metal belt as stable as possible. If unfortunately by accident, the glass broken, we will have insurance to cover the risk, because for all the glass from our company, we will purchase the insurance to cover all the risk for customers freely.

Q5:How can i get the best price?

In order to offer our best price for you, please send all the details as below for us:

a. what size and thickness of clear float glass/tempered glass/laminated glass are you looking for?

b. How about the approximate quantity?

c. Do you have any special requirement like drill holes, cut notches,cutouts, acid etched, silkscreen?

d. When do you need those glass?

- Q:Which glass factory has good glass?

- If the original piece of glass with good quality of Qingdao Jin Jing, Jiangmen farun, TGI, CSG, luoyang.... These glass plants are relatively stable, and is a large enterprise, if the processing technology is good, it depends on the processing unit of the process, this is not recommended.

- Q:Polypropylene short fiber and glass fiber if different

- Polypropylene fiber is resistant to acid and alkali, and glass fiber has poor alkali resistance.

- Q:Method for cutting thick glass

- Mechanical cutting glass:Mechanical cutting glass is the mechanical property of glass with low tensile stress. The diamond or emery is used to cut the surface, and the force is cut off because of tension.(1) when glass cutters do not cut very thick glass, they use diamond glass cutters inlaid with diamond at the ends of brass and cut ordinary flat glass, and often use super hard knife wheels. In addition, when cutting, adding kerosene and other liquids, the incision and tool life are better protection. In addition, to lead the soft glass tube, but also useful to cut the file.(2) diamond saw cutting diamond saw is not limited to glass, but also widely used in the cutting of germanium, silicon, ceramics, crystal and so on. Compared with common grit or ordinary abrasive saw, diamond saw has high cutting efficiency. Generally, grinding fluid is used during cutting. The bonding materials of diamond saw include metal, thermosetting resin, ceramic and so on. But the metal saw such as brass is usually cut. The thickness of saw blade is about 0.2 ~ 7ram. Cutting method is divided into outer circle cutting, inner circle cutting and band saw cutting.

- Q:What are these things that belong to the reactor's raw materials?

- The oil immersed reactor is also wound with aluminum (copper) wire, and the insulation is insulated paper and then soaked in oil.

- Q:I want to ask, if the home is already hollow glass, that still need to foil it?

- Insulating glass insulation effect is very good, but insulation, UV effect is not good. If a glass film is attached to the inner glass, the heat insulation effect is more marked, and the harmful ultraviolet ray can be effectively separated from the 99%, and the glass can be prevented from splashing after breaking.

- Q:The main raw material for the impact of float glass cost?

- Fuel prices: heavy oil, natural gas or coal, etc., because of the large number of long-term consumption, so it is also an important factor affecting product costs.

- Q:The benefits of natural thin wood planks

- Sheet material means a flat rectangular building material plate with a width of more than 2 times its thickness, usually made of flat rectangular building material, used as a wall, ceiling, or floor member. Also refers to the forging, rolling or casting of the metal plate, divided into thin plate, medium plate, thick plate, thick plate, usually made of standard size flat rectangular building material board.

- Q:What's the raw material for goldfish bowl?

- As for other containers: as long as you can hold water, do not fade, no smell, no harmful substances can be raised

- Q:FRP process piping manufacturing process?

- Glass tube wall structure from inside to outside are: glass fiber reinforced plastic lining layer, glass fiber reinforced plastic sub lining layer, glass fiber reinforced plastic winding layer, glass fiber reinforced plastic external protection layer.

- Q:May I ask what specific aspects of German foam glass and foam glass made in China are?

- Germany first foam glass from the production process is automatic production line, proportion of raw materials, mixing, grinding, into the furnace foaming, stripping, pipeline operations, and 24 hours of uninterrupted production, full computer monitoring, the whole process of online cutting, according to the requirements of automatic generation of the required thickness and size. 100% waste glass as raw material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heat Resistant Borosilicate Glass 3.3 used for Projector lens

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products