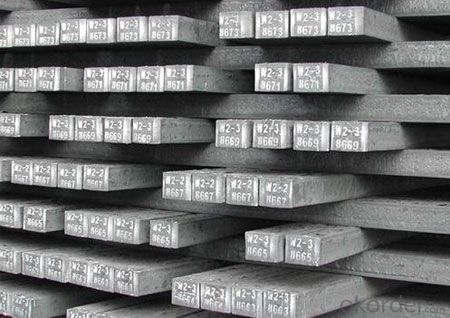

Steel Billets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Continue casting round billets

Process: EAF+LF+VD+Continue CASTING,Delivery condtion:Hot forged+Normalzied+Rough Machined+Q/T.

Boiler Pipe Billets

Forging Steel Ingots

Stainless Steel Round Billets

Billets for Structural Seamless Pipe

Casing Steel Billets

Billets for Oil Well Casing Pipe

Stainless Steel Square Billets

Forging Square Steel Billets

Carbon Steel Square Billets

Stainless Steel Round Billets

Forging Round Billets

Line Pipe Steel Billets

Forging Ingot | |

| Range | Material |

| 5t-150t | Carbon Steel Ingot、Alloy Steel Ingot、Bearing Steel、Wind Power Steel、Nuclear Power Steel、Steel Mould Or Special Material |

Heavy Casting Or Forging Steel Billets | |

Casing Steel Billets: Min QTY 200 Ton、Forging Steel Billets: Min QTY 60Ton | Cooperative development according to customer requirements. |

The Continuous Casting Round Billet | ||

Name | Material | Size |

Billets for Structural Seamless Pipe | 10#、20#、35#、45#、345B、27SiMn、20Mn2 | φ180mm-φ600mm |

Billets for Low&Medium Pressure Boiler Pipe | 20# | φ180mm-φ600mm |

Billets for high pressure boiler pipe | 20G、SA-192、SA-106B、SA-106C、SA-210A1、SA-210B、SA-210C、37Mn、34Mn2V、30CrMo、35CrMo、34CrMo4、SA335-P2、SA335-P11、SA335-P12、16MnG、25MnG、15MoG、16Mo3、13CrMo4-4、10CrMo9-10、15CrMoG、12Cr1MoVG | Φ180mm-Φ600mm |

Billets for Oil Well Casing Pipe | 37Mn5、34Mn6、25Mn2V、30Mn2V-36Mn2V、26CrMo4、32CrMo4、29MnCr6、29CrMo4-4、40CrMo4 | Φ180mm-Φ600mm |

Billets for Line Pipe | L245(B)、L245NB、X42(L290)、X46(L320)、X52(L360)、L320NB、L360NB、L245NCS、L290NCS、L360NCS | Φ180mm-Φ600mm |

Forging Round Steel Billets & Square Billets | 45#、50Mn、40Cr、GCr15、GCr15SiMn、Q345E、35CrMo、42CrMo、42CrMo4 | Round Steel Billets:φ180mm-φ600mm |

Stainless Steel Round Billets &Square Billets | 1Cr13、2Cr13、3Cr13、4Cr13、1Cr18Ni9Ti | Round Steel Billets:φ180mm-φ600mm |

- Q:What are the different types of defects that can occur during casting of steel billets?

- There are several types of defects that can occur during the casting of steel billets. These include shrinkage cavities, porosity, cracks, inclusions, surface irregularities, and segregation. Shrinkage cavities occur due to the solidification process and can result in voids or cavities in the billet. Porosity refers to the presence of gas or air pockets within the billet, which can weaken its structure. Cracks can occur due to thermal stresses or improper cooling, leading to structural weaknesses. Inclusions are foreign materials such as oxides or non-metallic particles that can be trapped within the billet, impacting its quality. Surface irregularities refer to imperfections on the surface of the billet, which can affect its appearance and structural integrity. Segregation is the uneven distribution of alloying elements within the steel billet, leading to variations in the material's properties. These defects can impact the overall quality and performance of the finished steel product.

- Q:What are the advantages of using steel billets in the oil and gas industry?

- There are several advantages of using steel billets in the oil and gas industry. Firstly, steel billets offer exceptional strength and durability, making them suitable for withstanding extreme conditions and high-pressure environments commonly found in the industry. Secondly, steel billets can be easily shaped and machined into various components, allowing for customization and flexibility in designing equipment and structures. Additionally, steel billets have excellent resistance to corrosion, which is crucial in preventing damage caused by exposure to harsh chemicals and corrosive environments. Lastly, steel billets have a high melting point, making them suitable for applications that involve high temperatures, such as refining and processing operations in the oil and gas industry.

- Q:How long do steel billets typically last?

- Steel billets typically last for a very long time. The lifespan of a steel billet depends on various factors such as the quality of the steel, the environment it is exposed to, and how it is used. Generally, high-quality steel billets that are properly stored and handled can last for several decades without any significant deterioration. However, if the billets are exposed to harsh environments or are not properly maintained, their lifespan may be shortened. It is important to note that steel billets can be recycled and reused, further extending their overall lifespan.

- Q:How are steel billets used in the production of railway components?

- Steel billets are an integral part of the production process for railway components. These billets, which are essentially semi-finished steel products, are used as the raw material for manufacturing various railway components such as rails, wheels, axles, and other structural parts. To produce railway components, the steel billets are first heated to a specific temperature to make them more malleable. This heating process is crucial as it allows the steel to be easily shaped and formed into the desired component. Once the billets have reached the required temperature, they are then transferred to the next stage of the production process. Here, they are subjected to various processes such as rolling, forging, and machining to transform them into the final shape and size required for the specific railway component. For instance, in the production of railway rails, the heated steel billets are passed through a series of rolling mills where they are gradually shaped and elongated into the desired rail profile. Similarly, for the production of wheels and axles, the billets are forged and machined to achieve the required dimensions and surface finish. The use of steel billets in the production of railway components ensures that the final products are strong, durable, and capable of withstanding the heavy loads and stresses associated with railway operations. The quality and characteristics of the steel billets play a vital role in determining the performance and longevity of the railway components. Overall, steel billets are crucial in the production of railway components as they provide the raw material that is shaped, formed, and processed to create the final products that are essential for the safe and efficient functioning of the railway system.

- Q:What are the different types of heat treatment processes used for steel billets?

- There are several different types of heat treatment processes used for steel billets. Some commonly used methods include annealing, normalizing, quenching and tempering, and case hardening. Each process has its own purpose and is used to achieve specific properties in the steel billets.

- Q:What are the properties of steel billets?

- Steel billets are semi-finished products that are typically rectangular in shape and serve as the starting point for the production of various steel products. They possess several distinct properties, including: 1. High strength: Steel billets have exceptional strength due to the presence of carbon and other alloying elements. This enables them to withstand heavy loads and provide structural integrity in various applications. 2. Ductility: Steel billets can be easily deformed without fracturing, making them highly ductile. This property allows for the shaping and forming of the billets into different products through processes such as rolling, forging, and extrusion. 3. Thermal conductivity: Steel billets have good thermal conductivity, meaning they can efficiently transfer heat. This property is particularly useful in applications that involve heat treatment or require heat dissipation, such as in the manufacturing of automotive parts or machinery. 4. Corrosion resistance: Steel billets can exhibit a certain level of corrosion resistance depending on their composition and surface treatment. However, they are generally prone to rusting if not properly protected, so additional measures like coatings or galvanization may be necessary. 5. Machinability: Steel billets are known for their machinability, which refers to their ability to be easily cut, drilled, or milled into desired shapes and sizes. This property makes them suitable for a wide range of machining operations, facilitating the production of intricate parts and components. 6. Recyclability: Steel billets are highly recyclable due to the inherent recyclability of steel as a material. This property not only reduces waste and environmental impact but also contributes to the sustainability of steel production. Overall, the properties of steel billets make them an essential and versatile material in various industries, including construction, automotive, machinery, and manufacturing.

- Q:What are the main uses of steel billets in the automotive industry?

- Various applications in the automotive industry make steel billets widely used. One of their primary uses involves the production of forged components, such as crankshafts, connecting rods, and camshafts. These components demand high strength and durability, qualities that steel billets possess and meet these requirements. Gears, axles, and transmission shafts also rely on steel billets for their manufacturing. These parts must withstand heavy loads and ensure smooth and efficient power transmission within the vehicle. Steel billets possess excellent mechanical properties, including high tensile strength and toughness, which make them the ideal choice for such applications. Furthermore, suspension components like control arms, steering knuckles, and suspension links depend on steel billets. These components play a crucial role in maintaining vehicle stability, control, and comfort. Steel billets are preferred for these parts due to their exceptional strength, stiffness, and impact resistance. Moreover, body and chassis components, such as pillars, beams, frames, and reinforcements, benefit from the use of steel billets. These components provide structural integrity and crash protection to the vehicle. Steel billets offer a superior strength-to-weight ratio, corrosion resistance, and formability, making them a popular choice for these safety-critical components. In conclusion, steel billets find applications in the automotive industry for forged components, gears and transmission parts, suspension components, and body and chassis components. Their exceptional mechanical properties are indispensable for building durable, reliable, and safe vehicles.

- Q:What are the different types of steel billet casting processes?

- There are several different types of steel billet casting processes, each with its own advantages and disadvantages. Some of the most commonly used processes include continuous casting, ingot casting, and direct chill casting. Continuous casting is a widely used method that involves pouring molten steel into a water-cooled mold, which then solidifies into a continuous strand or billet. This process offers high production rates, improved quality control, and reduced energy consumption compared to other methods. Continuous casting is ideal for producing large volumes of steel billets with consistent dimensions. Ingot casting, on the other hand, is an older and less commonly used method. It involves pouring molten steel into individual molds called ingot molds, which solidify into solid blocks or ingots. Once solidified, the ingots are then reheated and shaped into billets through processes like rolling or forging. Ingot casting allows for greater flexibility in terms of alloy composition and size, but it typically requires more energy and has a slower production rate compared to continuous casting. Direct chill casting is another popular process, especially for producing aluminum alloys. It involves pouring molten steel into a water-cooled mold, similar to continuous casting. The main difference is that direct chill casting uses a rotating mold to create a cylindrical, or sometimes rectangular, billet. This process offers better control over the solidification process, resulting in improved microstructure and mechanical properties of the billet. Other less common steel billet casting processes include electromagnetic casting, where an electromagnetic field is used to control the flow of molten steel, and centrifugal casting, which involves pouring molten steel into a rotating mold to create cylindrical billets. These methods are typically used for specialized applications and are not as widely adopted as continuous casting or ingot casting. In conclusion, the different types of steel billet casting processes include continuous casting, ingot casting, direct chill casting, electromagnetic casting, and centrifugal casting. Each method offers unique advantages and is suitable for different production requirements and steel grades. The choice of casting process depends on factors such as desired billet size, production volume, alloy composition, and cost considerations.

- Q:How are steel billets different from steel ingots?

- Steel billets and steel ingots are both semi-finished steel products, but they differ in terms of their shape, size, and manufacturing process. Firstly, the shape of steel billets and steel ingots is different. Steel billets are typically square or rectangular in shape, with specific dimensions that are determined by the production requirements. On the other hand, steel ingots have a more irregular shape, often resembling a large block or loaf. The shape of the ingot is determined by the mold in which it is cast. Secondly, the size of steel billets and steel ingots also varies. Steel billets are generally smaller in size compared to ingots. Billets are typically produced in smaller cross-sectional areas and lengths, making them more suitable for further processing. Steel ingots, on the other hand, are larger and heavier, as they are cast in molds that can accommodate a greater volume of molten steel. Lastly, the manufacturing process for steel billets and steel ingots differs. Steel billets are typically produced through a process called continuous casting, where molten steel is poured into a water-cooled mold to solidify into the desired shape. This process allows for a more controlled and efficient production of billets. On the other hand, steel ingots are generally produced through casting in open or closed molds, where the molten steel is poured and left to solidify. This process is often slower and less precise compared to continuous casting. In summary, steel billets and steel ingots differ in terms of their shape, size, and manufacturing process. Billets are square or rectangular in shape, smaller in size, and produced through continuous casting, while ingots have an irregular shape, larger in size, and produced through casting in molds. Both products serve as essential raw materials for the production of various steel products.

- Q:What are the different types of steel billet rolling techniques?

- There are several different types of steel billet rolling techniques, including hot rolling, cold rolling, and continuous casting.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Billets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords