Solar Cell for Electricity 3KW Off-grid Solar Energy Generator System for Home

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

156x156 A Grade B Grade PV Silicon Solar Cell for Solar Panel

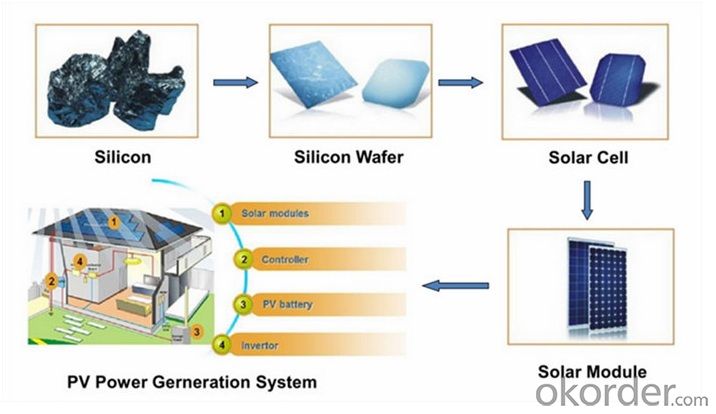

Solar Module Summarize

Solar Module is the core part of solar PV power systems,also is the highest value part of it. The function of Solor Module is to convert the sun's radiation to electrical energy, or transfer it to battery and store in it, or to drive the load running.

The Product has been widely used in space and ground, it mainly used for power generation systems, charging systems, road lighting and traffic signs areas. It could offer a wide range of power and voltage, and with high conversion efficiency, and long service life.

Physical characteristics

Dimension | 156mm X 156 mm ±0.5mm |

Wafer Thickness | 200um ±30um |

Front(-) | Four 1.1mm wide bus bars(silver) with distance 39mm, Acid texturized surface with blue silicon nitride AR coating. |

Back(+) | 2.4mm wide silver/aluminum soldering pads, aluminum back surface field. |

Product Pictures

- Q:What are the different wafer orientations used in solar silicon wafer production?

- The different wafer orientations used in solar silicon wafer production are mainly three: (1) the most commonly used orientation is the <100> orientation, where the crystal structure is aligned along the <100> crystallographic direction; (2) the <111> orientation, which has a different crystal structure alignment; and (3) the <110> orientation, which is less commonly used but still finds some applications in certain solar cell designs.

- Q:Can solar silicon wafers be used in concentrated photovoltaic systems?

- Yes, solar silicon wafers can be used in concentrated photovoltaic systems. Concentrated photovoltaic systems use lenses or mirrors to concentrate sunlight onto smaller, more efficient solar cells. These systems can utilize traditional silicon-based solar cells, including silicon wafers, to capture and convert the concentrated sunlight into electricity.

- Q:How long does a solar silicon wafer typically last?

- A solar silicon wafer typically lasts for several decades, with an average lifespan ranging from 25 to 30 years.

- Q:Can solar silicon wafers be used in concentrated solar power (CSP) systems?

- Yes, solar silicon wafers can be used in concentrated solar power (CSP) systems. These wafers can be used to create photovoltaic cells that convert sunlight into electricity. However, it is important to note that CSP systems typically utilize other technologies, such as mirrors or lenses, to concentrate sunlight onto a receiver. So while solar silicon wafers can be a component of CSP systems, they are not the sole technology used in these systems.

- Q:How is a glass cover attached to a solar silicon wafer?

- A glass cover is typically attached to a solar silicon wafer using a specialized adhesive or encapsulant material. This material is applied between the glass cover and the wafer, creating a strong bond that ensures the cover stays securely in place. Additionally, the adhesive or encapsulant also provides protection against moisture, dust, and other environmental factors, safeguarding the delicate solar cells within the wafer.

- Q:Can solar silicon wafers be used in thin-film solar cell technology?

- No, solar silicon wafers cannot be used in thin-film solar cell technology. Thin-film solar cells use different materials, such as amorphous silicon, cadmium telluride, or copper indium gallium selenide, to capture sunlight and convert it into electricity.

- Q:Can solar silicon wafers be used in smart city infrastructure?

- Yes, solar silicon wafers can be used in smart city infrastructure. Silicon wafers are the key component in solar panels, which can be integrated into various aspects of smart city infrastructure such as smart streetlights, smart grids, and solar-powered sensors. These solar panels generate clean energy from sunlight, providing sustainable power for different smart city applications.

- Q:What is the expected efficiency improvement for thin-film solar silicon wafers?

- The expected efficiency improvement for thin-film solar silicon wafers is anticipated to be significant, with estimates suggesting a potential increase of around 50% in efficiency compared to traditional silicon wafers.

- Q:What is the cost of manufacturing a solar silicon wafer?

- The cost of manufacturing a solar silicon wafer can vary depending on various factors such as the size, quality, and production volume. However, on average, the cost can range from a few dollars to around $10 per wafer.

- Q:What is the typical lifetime energy yield of a solar silicon wafer?

- The typical lifetime energy yield of a solar silicon wafer varies depending on various factors such as the efficiency of the solar cells, the geographical location, and the maintenance of the solar panel system. On average, a solar silicon wafer can generate enough energy to offset its initial embodied energy within 1-4 years. Over its lifetime, a solar silicon wafer can produce around 10-20 times more energy than was used in its manufacturing process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Solar Cell for Electricity 3KW Off-grid Solar Energy Generator System for Home

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords