Re-boiler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Re-boiler is ahigh-efficient heat exchanging equipment used in alcohol, solvent, foodferment, pharmaceutical, petrochemical, refrigeration, organic chemistry, metallurgicalindustry, suitable for convection heat transfer of liquidtoliquid,gas to gas,gas to liquid. Re-boiler is made of carbon steel and stainless steel.

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

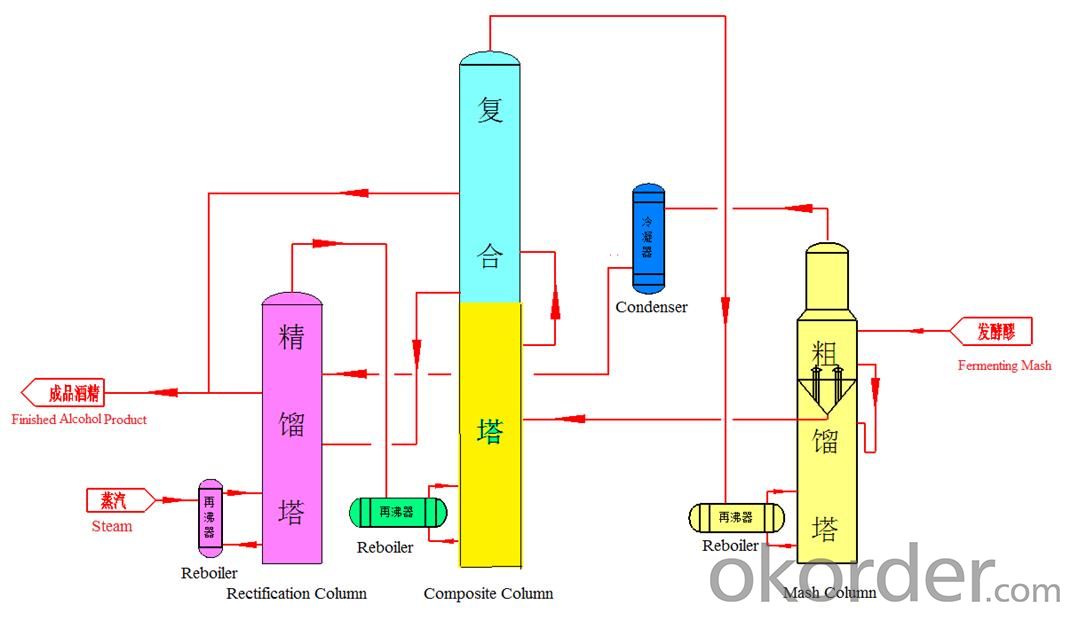

Double-Mash-Column Three-Effect DistillationProcess

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

Weown advanced machining equipment and product testing equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q:Hi,If we have a high efficiency furnace that is getting fresh air from the oustide, would there be any use for an air to air heat exchanger?Thanks in advance.

- No it is a waste of money. They are for homes that have very very tight seales on doors and windows where outside air is not getting in anywhere

- Q:Central gas heat. Sequence is: (1) t-stat asks for heat, (2) exhaust blower kicks in and makes exhaust pressure switch (3) glow plugs fire (4) gas flow starts (5) flames, heat exchanger heats up (6) fan limit kicks in and heats house.This works fine ... sometimes. It's easy to find a broken component, harder to find a temperamental one. Where would you start?

- Start by eliminating components. First jumper out the t-stat. Take it out of the loop. See if the furnace acts up. Next the pressure switch, etc. etc. Sooner of later you will find the culprit. Pressure switches rarely go bad. And if the vent is partially blocked it could cause intermittent problems. Check the filter. That could cause random limit issues. May be a dirty flame sensor that turns off the burners. T-stat problems will turn off the exhaust blower. If the exhaust blower still runs and burners shut off, may be vent or sensor issues! God luck! Hope this helps!

- Q:Process water with a specific heat capacity of 4.182 KJ Kg-1 K -1 flows at a rate of 0.050 Kg s-1 through a heat exchanger where its temperature is increased from 16C to 85C. Heat is supplied by exhaust gases (mean specific heat capacity of 1.075 KJ Kg-1 K-1) which enter the heat exchanger at a temperature of 420C. If the mass flowrate of the exhaust gases is 0.044 kg s-1, determine their outlet temperature.

- Heat taken up by water = W = 0.05 ? 4.182 ? (85-16) = 14.43 kJ/s = 14.43 kW. Let outlet temperature of exhaust gas = T The above power (= heat quantity per second) is removed from the gas, so we may write: (420-T) ? 1.075 ? 0.044 = 14.43 giving T = [(420 ? 1.075 ? 0.044) – 14.43]/(1.075 ? 0.044), i.e. T = 114.93?C.

- Q:why the temperatures of water decreases after come out from the heat exchanger?

- That is the work of a heat exchanger! The temperature of the water will decrease if the other fluid that is exchanging heat is colder than that of the water. Heat will simply flow from the water, through the tubing to the other fluid whose temperature will increase depending on its heat capacity or phase

- Q:I am using three passes for the heat exchanger. The water flows due to gravity. The tube carries hot water and the shell, cold water. The type of flow is counter flow. The hot stream loses heat to the cold stream twice, as the length is limited and i want to ensure that maximum amt of heat is transferred. The problem is, i don't want the reverse to happen, in case the cold stream is already hotter than the hot stream at exit of the first pass. How do i determine the temperature of the streams at the outlet, for a given mass flow rate, length and dia of pipes, specific heats of the pipe material?? The tubes are horizontally placed, with an inlet on the top and outlet at the bottom.

- understand the flow arrgt graph.

- Q:wath is ,inox-radial heating surface?

- An inox-radial heating surface is a round, compact heat exchanger which is used primarily in water heating systems. It has been described as a hollow slinky. Its just the same as any other heat exchanger just a different shape.

- Q:why bypass system used on heat exchanger?

- reckoning on the popular of the steam, it ought to have deposited minerals contained in the exchanger tubes and blocked them off. reckoning on the rigidity topersistent the steam by the tubes, there would no longer be sufficient to do the activity if the tubes become complete of steam condensate. How is the steam bypass managed? Do it use a administration valve? steam capture? or is it in simple terms open to the ambience?

- Q:The house I live in has fan-forced heating that consists of a fan blower and a gas heater. When the thermostat goes on, the fan and gas unit turns on. If the circut for the fan blower is cut off when the thermostat kicks on and the heat is supposed to be on, will the gas unit burn out because the fan isn't blowing?

- Some space heaters have accessory blowers or fans that can be added but are not required. It is not clear from your description weather you have this type or a typical forced air furnace that has duct work attached. A forced air furnace needs airflow or the burners will cut out shortly after the burners come on due to limit switches that detect overheating.

- Q:Spent steam from an electric generating plant leaves the turbines at 120 degrees C and is cooled to 90 degrees C liquid water by water from a cooling tower in a heat exchanger. How much heat is removed by the cooling tower for each kg of spent steam?

- specific heat water is 4186 J/kgC heat of vaporization of water is 2.256 MJ/kg specific heat of steam is 2100 J/kgK energy is removed to cool it to 100 C (assuming atmospheric pressure), then energy to condense it to liquid, then more to cool it from 100 to 90 C part 1) E = 2100 J/kgK x 1kg x 20C = 42000 J part 2) E = 2.256 MJ/kg x 1kg = 2256000 J part 3) E = 4186 J/kgC x 1 kg x 10 = 41860 J adding them up total = 2339900 J

- Q:I am trying to size a plate heat exchanger. I want to heat water from 22C to 90C. The flow rate of the water is 3.333kg/s.Help!

- Download okorder /.. Its a trial version and design it with the help of it easily.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Re-boiler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords