Gantry Machining Center For Boring Drilling Milling Tapping

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1. The machine tool foundation is made of high-quality and high-strength cast iron gantry frame structure, with good rigidity, seismic resistance, and accuracy retention.

2. Fixed beam structure, the beam adopts a composite guide rail form of "linear hardway" combination of vertical orthogonal linear guide rail and sliding hard rail, with good rigidity.

3. The X and Y axes adopt heavy-duty linear rolling rails with large bearing capacity and high accuracy. The Z-axis is a six-sided hard rail structure, ensuring the rigidity of the Z-axis feed and the retention of high-precision feed.

4. Taiwan's famous high-speed spindle unit (6000 rpm) has optional rotational speeds of 3000, 4000, 6000 rpm.

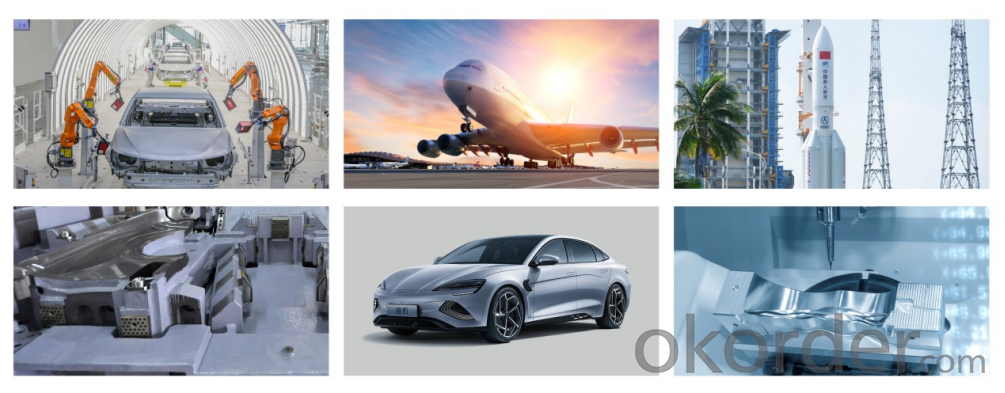

5. Suitable for precision machining of large workpieces such as aerospace, automobiles, textile machines, molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Dispose

Technical Parameter

Application Area

Suitable for precision machining of large workpieces such as aerospace, automobiles, textile , molds, packaging machinery, mining equipment, etc. It can automatically complete complex machining processes such as boring, drilling, milling, tapping, etc.

Package

Global Sales Market

Cooperative Clients

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-180 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q:How does the law processing center use online processing?

- In the mdi state, press the offset key, set the IO to 4, run the way to DNC, press the PROG key, press the extended key (>) to find the display program list, according to the previous serial number 0001 input 1 call 0001 program

- Q:Machining center z axis tooling

- And then in the relative coordinates of Z to zero. Behind the second to the third ... ... and so on, are in accordance with the length of the first tool to compensate

- Q:Number of CNC lathes, controlled bed and machining center?

- CNC milling machines are generally processing parts of the waist hole, keyway, plane;

- Q:Machining center M19

- The purpose of the boring tool is to stop the automatic positioning of the hole at the bottom of the hole (the direction of the tool nose is the direction when you put the knife) and then move the Q value to lift the workpiece surface G98 to G50 Z50.H * in the Z50.

- Q:What brand of domestic machine tools? Is there a five-axis machining center

- Innovation and development of a large number of new products into the important areas of national economy.

- Q:Which big god gets advice, cnc processing center g code g28g98g99 in the end what is the meaning. To be detailed. Have labor Thank you

- G99: After drilling a hole, the tool returns to point R to move quickly to the next hole.

- Q:Comparison of CNC milling machine and CNC machining center machine differences

- The machining center has the function of automatic exchange of tools. By installing different tools in the magazine, it can change the machining tool on the spindle by means of automatic tool changer in one clamping, realize drilling, boring, hinge, tapping,

- Q:Five-sided machining center and five-axis machining center What is the difference

- Refers to the general horizontal machining center, plus a shaft. Refers to the table has five movement direction.

- Q:Are there any differences between CNC and machining centers and CNC milling machines?

- The specification is also the official statement is also the basis of the function of the machine to define.

- Q:How does the machining center handle the taper hole?

- You can use the round nose knife from the D120MM from top to bottom or from before and after (according to your processing center is vertical or horizontal) and other high processing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gantry Machining Center For Boring Drilling Milling Tapping

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches