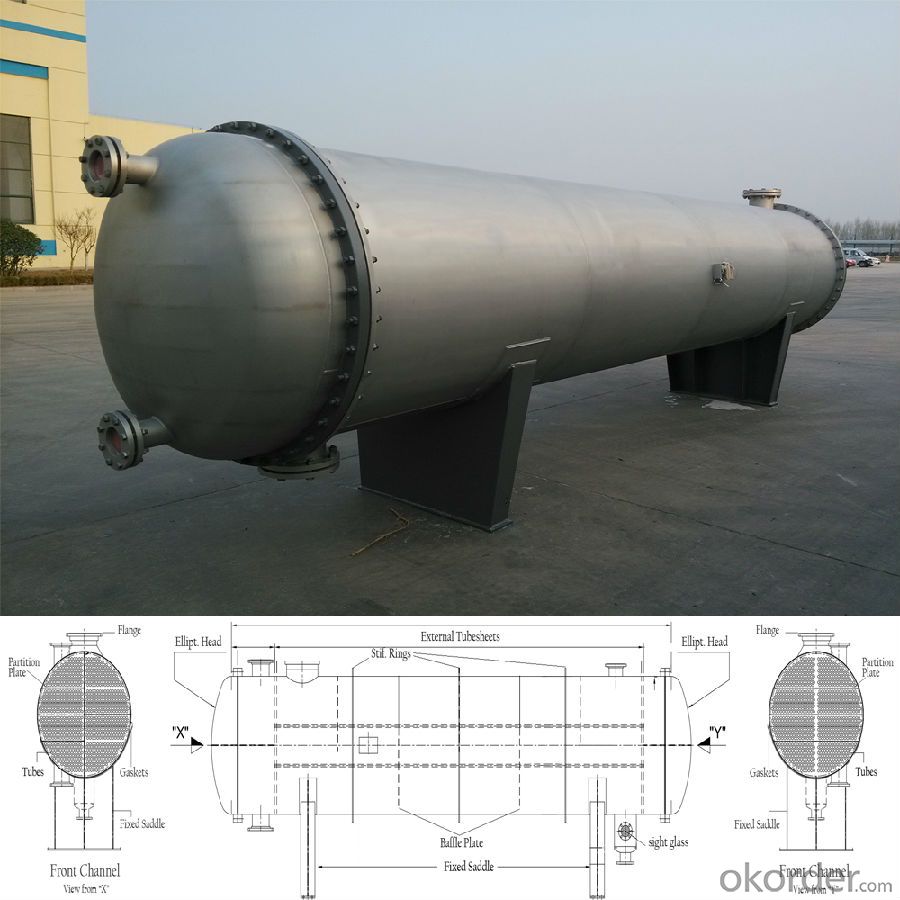

pre-heater

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-heater is a high-efficient heat exchanging equipment used in alcohol, solvent, foodferment, pharmaceutical, petrochemical, refrigeration, organic chemistry, metallurgicalindustry, suitable for convection heat transfer of liquidtoliquid,gas to gas,gas to liquid.

The heatexchangeris divided into tubular heat exchanger, spiral plate heat exchanger.And the tubular heat exchanger comprises condenser, Pre-heater, Re-boiler,Evaporator, drying machine. The spiral plate heat exchanger comprisesnon-dismountable and dismountable exchanger.

The heatexchanger is made of carbon steel and stainless steel.

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latest Five-Column Three-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

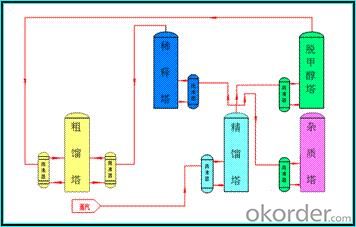

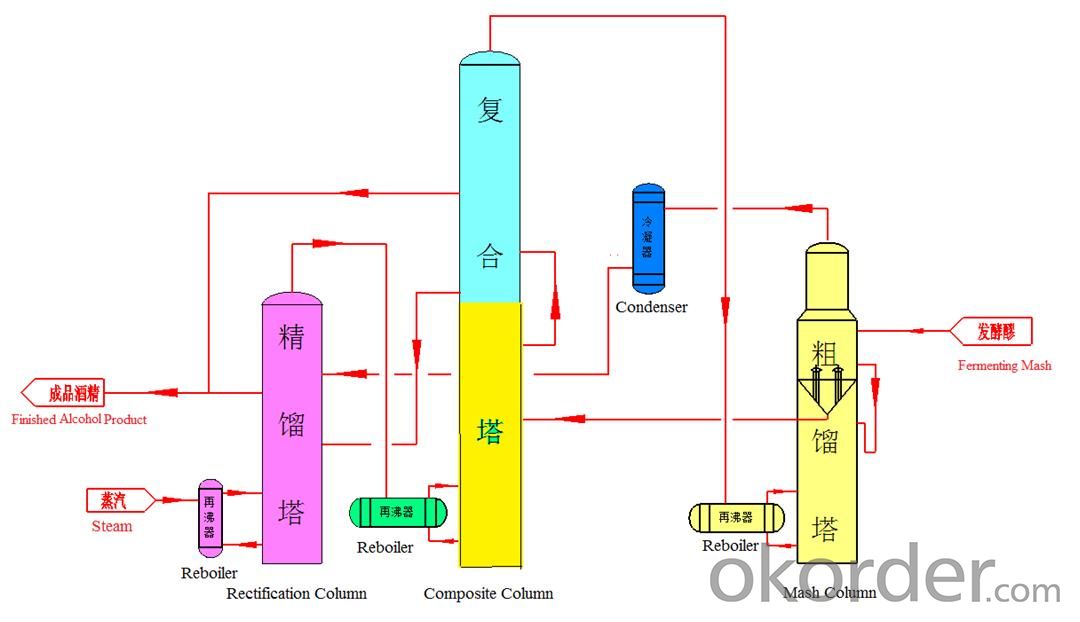

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;it saves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce 6 full sets of equipment (including crushing section, liquefying saccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2).We can reach the project site after receiving the user’s notification.

6.Package & Transport

- Q:I need to heat about 3500 gallons of biodeisel from 20°C to 45°C, i was thinking in using a Fired Heater and a Heat Exchanger, this is only for femonstrational purposes, but can anyone tell me an alternative mean to heat Biodiesel, less complicated and for god sake cheaper!!

- A fired heater will probably be the cheapest way. You could try electric heaters (you can buy the elements from water heaters at appliance repair shops - they use 240V), but the electricity cost will probably be more than for the fuel (if you were thinking gas/petrol, maybe propane or natural gas will be cheaper). I also don't know if I'd be comfortable putting electric elements in 3500 gallons of biodiesel - I've seen a few kitchen fires, and burning oil is never pleasant. You could also consider solar heating - it would be cheaper in the long run, but any efficient installation would have to involve heating panels, piping, pumps, and a lot of water. You could try painting your tank black, but that probably won't work very well unless you live in the desert or high plains.

- Q:The home is an older home that I am going to use as a rental. I know nothing about forced air or whether there is duct work. Should I assume there is and in that case only need a unit? Thanks!

- G--o--o--l-l-lly!! Are you asking for an out-and-out quote in final cost $s? There are ALL KINDS of specific information that anyone would have to know before giving you even the WILDEST estimate of cost, e.g.: 1. Is it a true forced-air heating system with a fixed furnace and ducting to the various rooms? Does the blower have enough capacity to overcome the extra resistance of forcing the air past the new cooling coil for central heating cooling? 2. Is the furnace in a basement or on the floor level of the house and is it in good operating condition with no problems in proper air circulation to all outlets and insulation on the outside of all ducts in good, SEALED condition? 3. Is the fuurnace of the type that is designed to accept a new add-on cooling coil for air conditioning and have enough clearance between it and a ceiling or floor above before the connection to the existing plenum chamber? 4. How many BTU/hr. heat removal that will be required to do the job will determine the cost of the new refrigeration compressor/heat exchanger unit, complete with 220+V electrical hook-up and connecting cooling gas piping to and from the cooling coil necessary to provide the needed heat removal (usually with a little extra capacity)? 5. How many manhours of expensive electricians, plumbers, carpenters, and very probably insulators, etc. will be required to finish the job? I don't know, but as you can see, it will be a fairly complex project and I believe you would be well-advised to seek a good reputable and reasonable general contractor to do the job. For it to be done RIGHT it ain't gunna be cheap!

- Q:I'm trying to compare the advantages and disadvantages of using a steam jacket on a reactor vs. an external heat exchanger. The steam jacket would be directly heating the reactor and the external heat exchanger would be heating the two inlet streams to this reactor. Please give a few advantages and disadvantages to each.

- The steam jacket will give you much less surface area than an external heat exchanger. In addition, the heat transfer coefficient on the steam jacketed vessel will be poor unless you have a very high degree of mixing, and even then, I doubt you can get the velocity at the vessel wall to be in the same range of a properly sized external heat exchanger The only possible advantage of the steam jacketed vessel is the cost. You will save the cost of the heat exchanger. Since you will already have a pump to transfer the vessel contents, you don't save money there, and if you have an agitator installed, you probably won't save that much.

- Q:engineering

- It seems your question has to do with when does a heat exchanger get fouled enough to require cleaning. That is strictly a matter of economics. You can simply look at the inlet and outlet temperatures and do a heat transfer calculation to determine when the cost of shutting down and cleaning is less than the amount of heat (or cooling) you are losing.

- Q:I have two fluids entering a shell and tube heat exchanger.One enters at 393K and leaves at 323KThe other fluid enters at 353K and leaves at 308K.Is this even possible?

- It is not clear if these are measured numbers or calculated numbers. In the case of measured numbers I have seen such things happen due to errors in temperature measurement. In the case of calculated numbers I can only see a case where a fluid can enter an exchanger at a given temperature and leave at the same temperature while the other fluids is cooled down. That is the case of liquid such as a refrigerant liquid that enters the exchanger at its boiling temperature, boils and then leaves the exchanger at the boiling temperature.

- Q:I need help!

- You have to google this one to get a decent explanation of how it works, because it is kind of extensive. The basic premise is that tubes of glycol are circulated in about 1000 feet of tubing to pick up the heat of the earth which is about 55 degrees in the northern areas of the country all the time. This glycol is circulated thru the condenser of the air conditioner/heat pump to make the refrigerant 55F instead of relying on the air temperature. Heat pumps that get their heat from the air don't work well when the air temperature drops to below 40F, so this is where geothermal shines because it doesn't drop below 55F and the cooling fluid is a liquid instead of a gas, like air , so it transfers heat much better. Heat pumps get more energy from the glycol earth heat than it takes to run the compressor. So if your compressor uses 2 kwh of power it might be able to get 8 kwh of heat from the ground temperature. That is the big attraction. A normal electric heater would use 2 kwh of electricity to make 2 kwh of heat. A geothermal heat pumps works by using the earth heat of 55F to boil the refrigerant which boils at maybe -40F. So the temp of the earth at 55F looks downright balmy. When the refrigerant is boiled it is compressed and condensed which releases the heat of the compression plus the heat from the earth. The downside is the expense. At a minimum, for a small house it is about $7000 dollars as opposed to an air heat pump which would be about $3500. Big systems for large houses can run close to $20000

- Q:Why is the heat exchanger on a fridge painted matt black?

- Black absorbs heat the most efficiently of all colors. White reflects it the most. You want the exchanger to be as efficient as possible.

- Q:I m doing a Project on designing a heat exchanger for a evporative cooling. any idears?

- You could use courrogated cardboard from a box and a small fan. Place the cardboard in a tray of water, the water be drawn into the cardboard by capillary action. The courrogations gives you more surface area for evaporation. Use the fan to blow air across the cardboard. As the water evaporates, it will remove heat from the system. I seem to remember a man in Arizona built a full scale evaporative cooling tower for his house back in the 80's using this technology. JeffM

- Q:My furance runs, but the Firebox is damaged with Rust. Furance company told me to get a new one. The furnace runs but I am not using it. Can the box be replaced? and Who would do such a repair if it's possible. Unit is from 95, and has an energy star label on it. Unit is only used for Heat, not hot water.

- If this is a forced air furnace; I'll tell you a secret .....Furnace heat exchanger is probably still under warranty. Problem is that its a major job to replace because most of the time the furnace has to be pulled, completely disassembled, and then put back in place. The contractor is going to make his money either way and its going to be most of the cost of a new one anyway when you take all things into consideration. You will spend all that money and still have a 12 year old piece of equipment that has no warranty on any parts other than the heat exchanger. When you consider that a call to repair any other part is going to be several hundred by the time its done, sometimes its just good economics to replace it when you can buy a standard furnace that has a 10 year warranty on everything and just be done with the problem.

- Q:I cleaned the burners but still doing the same thing. My video of it.

- front not attached completely

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

pre-heater

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords