The spiral plate heat exchanger (Non-detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. Thespiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

Nominal heat transfer areaNominal heat transfer areaNominal heat transfer area | Channel Spacing | Calculate heat transfer area | handling capacity(flow rate: 1m/sec) | Nozzle nominal diameter | Model | I6T quality II6T quality | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

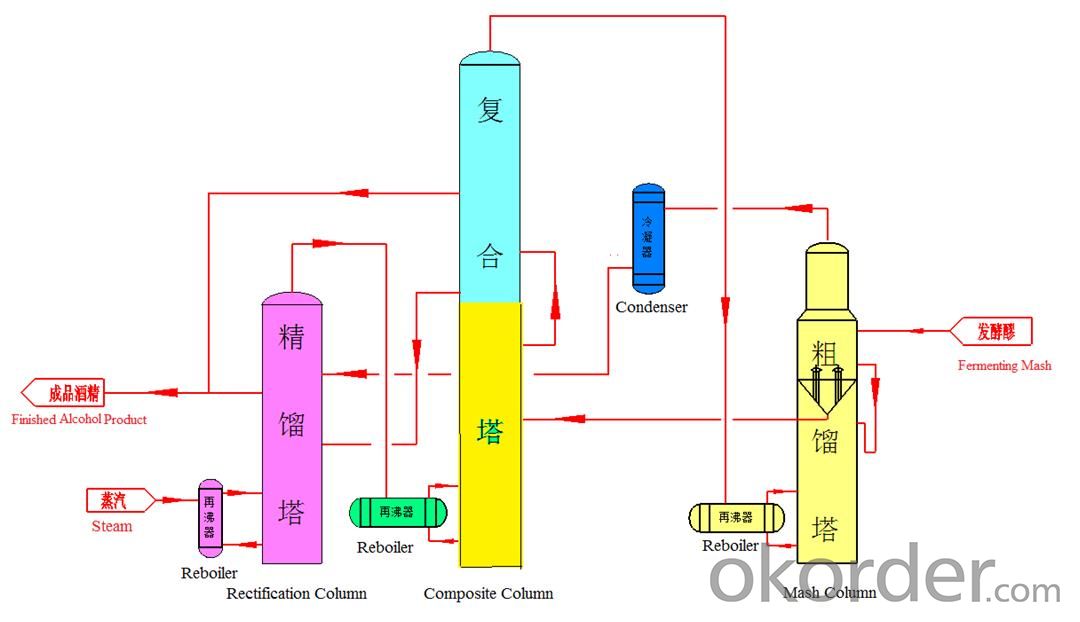

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q:we were given a hot tub but the motor and i think pump but we are not sure, do not work. We have no idea about hot tubs. All the model info and quot;stuffquot; has been worn off the actual piece with info.Here is the info we have from the pieces left.HEATFLO HEAT TRANSFER SYSTEM, ULTRA JET...can anyone help us and tell us what we need to get this going?a motor and pump?we do not have a lot of money so were looking for a used one...any assistance would be appreciated!thank you

- Hire a hot tub mechanic to help you. You state you don't have a lot of money. So don't waste what you have by replacing parts you don't need in an attempt to fix something that may not be broke. And yahoo is full of silly people who have no clue what they are talking about. Taking advise seen on here is rather silly.

- Q:The unit is only about 6 years old. I had the ducts and A/C unit cleaned two days ago. Could they have done something to break it? or else what could it be? It should not break after 6 years...

- Well when i bite into a york pepper mint patty I get a coooool sensation your heating element or thermostat is out or going out

- Q:and shall it be vertical/horizontal? where shall I put alcohol in shell or tube? I do have a 110 C temp difference do I have to use a floating head?

- I don't agree that the cooling or heating medium is on the shell side. Typically these are on the shell side. That is specially true when boiling or evaporating a liquid. You want to have an extra large shell to permit the separation of the vapor from the boiling liquid. In the case of a cooling medium (usually water) you want to be able to clean the heat transfer area and that is easier to do if the cooling medium is on the tube side. As to the floating head. Most of the time the designer would rather build a U-tube bundle if possible in a kettle type design. That eliminates problems with a floating head that can leak and have other problems. This would be a BKU TEMA configuration. It would also be a horizontal design because that best for easy access for maintenance.

- Q:I have a hot tub that contains approximately 500 gallons of water and would like to try heating it with a wood fire. I currently have a 20 pound propane tank that I have cut holes in that I was thinking I could place over the fire and have water run through it. Another thing I have seen is a big spiral of soft copper tube placed in the fire. How I understand it, it is simply the surface area that I care about. To heat the water in any sort of efficient way, do I need to go buy copper tube, or will the propane tank work. I understand that the water coming out of the copper spiral would be much hotter, but would they eventually heat the hot tub in about the same amount of time?

- As you probably know, there are several factors to account for, but let's talk about the major ones. Since you're going to use the same circulator pump with either the tank or the tubing, let's assume that you'd have roughly the same flow rate for each option. And let's say I also take your statement at face value: I understand that the water coming out of the copper spiral would be much hotter . . . The circulating water is the carrier for the heat calories from the fire to the tub. If it's much hotter coming out of the tubing than the tank, then, for a given amount of time, the tubing will carry many more calories than the tank solution would. So, roughly speaking, if the water output from the tubing is twice as hot as that from the tank, then it will be transporting twice as many calories per unit time, and the tub will heat up twice as fast--i.e. in ~ half the time. Regardless of the material you use, the ideal geometry for a heat exchanger will expose each molecule of the conducting fluid to the heat source as long as it takes to make them the same temperature before it leaves the exchanger. That's why automobile radiators are built like a fine honeycomb mesh--a molecule of water has a good chance of being exposed to the cooling air before it exits the radiator. That's where the surface area guideline comes in: The more the surface area of the exchanger (for a given flow rate), the more heat will be exchanged simply because of physical contact. In a sense, the tank you're proposing to use would be one of the worst exchangers, because very few of the water molecules would have direct contact with the wall of the tank before they exit the other end. The second factor is the thermal conductivity of the exchanger, which measures how fast heat flows through the material. Here copper, with a k = 400, has a big advantage over, say, steel, where k = 43. (See Source 1.) .

- Q:does anyone know how to size duct work using heat exchanger with outside wood furnace?

- I need to know the cfm of the air handler.If you don't know what size air handler,then I need to know the square footage of the area you are heating.

- Q:The concept (Buoyancy Assisted Airship) deserves a single syllable word that describes a rigid airship whose buoyancy is controllable or variable.I suggest zep. It's in usage already, but undefined. One might incorrectly call a blimp a zep.

- The term zep is illiterate slang, and should not be used. Please don't insult the memory of Count Ferdinand von Zeppelin by using that flippant little expression. Thank you very much. Please do an internet search on rigid airship and learn more about airships: what they are, how they work, and what has been tried in the past, before you start asking questions that don't make a whole lot of sense. How would you use waste heat from an engine to increase the lift of an airship? There does not seem to be any practical way, and the question seems-frankly-nonsensical. Engines provide forward thrust to move the airship. Lift is provided by lighter-than-air gas. The airship is already full of gas and is at the maximum lifting capacity provided by its gas volume. Heating the lifting gas would only waste gas by forcing some of it to be released into the atmosphere. Please give up this line of inquiry and trust the hundreds of very smart people who have studied and experimented with all aspects of lighter than air flight now for more than 10 years. Everything that might work has been tried.

- Q:Is that a bad thing to do? Sometimes ill be waiting for someone that im giving a ride and its cold obviously but i dont want to waste gas so i turn the heat on without turning on the engine. Will that harm my car? How and to what degree? I will award a best answer. Thanks!

- The engine must be running the coolant circulating in order to have heat. The heater is a heat exchanger, meaning the hot coolant passes through a small radiator. Air is forced through the rad. The heat from the coolant is absorbed on the cooling fins of the rad. The air forced though the rad, then heats up, this is what produces heat to the interior of the vehicle. ???

- Q:does anyone know why a 2002 ford taurus would not thrwow any heat.checked the radiator and changed the thermos

- check your heat exchanger and see if the plug has come loose or see if the heater hose is plugged

- Q:I noticed my furnace occasionally making a whoosh sound and the burner flames pop out of the burner chamber (but still inside the unit). My friend, an HVAC guy says that the heat exchanger is bad and it is sucking air into the system. He said that I need a new furnace. It still runs fine, but this sound and occasional flame are obviously worrisome. The unit is clean and there is no major debris inside. It's in a small apartment and I don't run it continuously, and it's original to the unit (24 years). Any way to avoid a major replacement by fixing?

- If it's 24 years old, you could get a much cheaper running unit, and save money. I replaced mine a couple of years ago and I've figured it will pay me back in another couple of years with fuel savings.

- Q:I don't understand why my home heating unit blow out heat then ice cold air. When I have the thermostst set to a degree and heat. Please help me with answers

- As your furnace cycles off, the burner shuts off but the flue blower keeps running to exhaust the burner chamber. At the same time the circulation blower stays on until after the flue blower shuts off. During this time there is no air being heated and the only air being circulated is unheated return air.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

The spiral plate heat exchanger (Non-detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords