Mono Solar Cells156mm*156mm in Bulk Quantity Low Price Stock 20.0

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

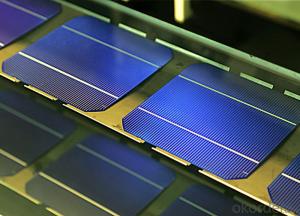

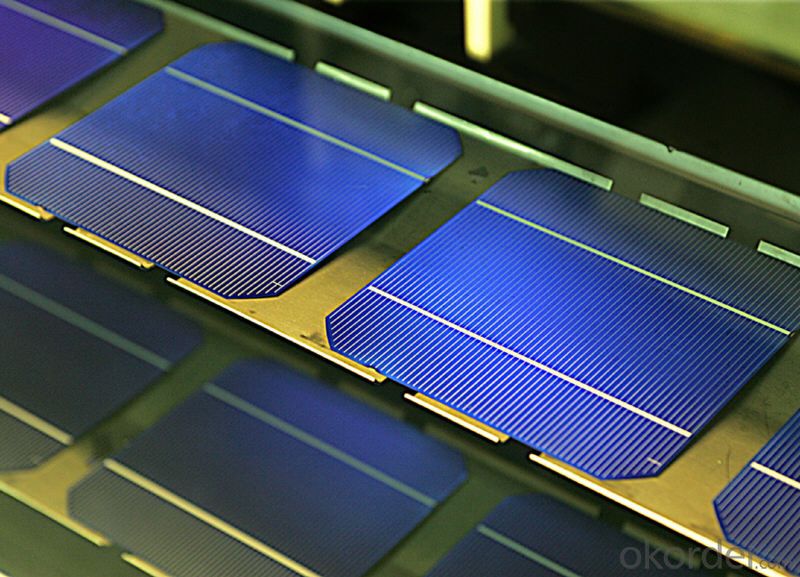

- Up to 20.0% efficiency, one of the highest performing mono crystalline cells on the market

- Three bus bars boosts current collection over the entire cell area, leading to higher fill factors

- Blue anti-reflecting coating allows more sunlight be captured and converted to electricity

- Finer, closer fingers improves charge collections for improved energy yield

- Lower light-induced degradation leads to greater power output over the entire module lifetime

- All solar cells are tightly classified to optimize output of module

- Maximum yield and longevity due to hotspot prevention

- Premium appearance results in a highly uniform and aesthetically appealing module

Specification

- Product Mono-crystalline silicon solar cell

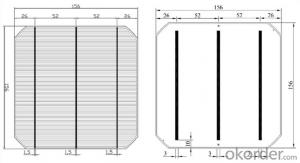

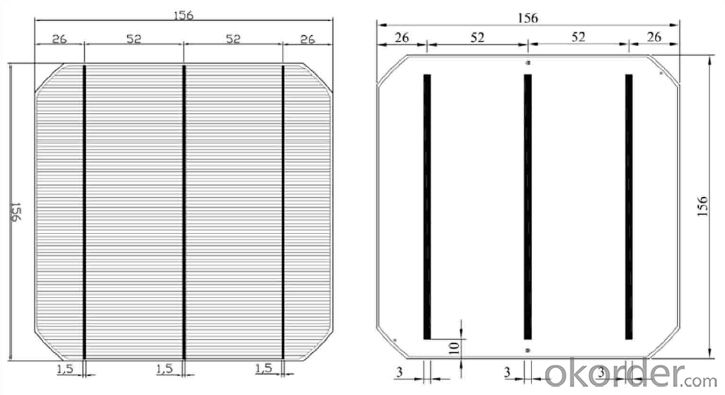

- Dimension 156 mm x 156 mm ± 0.5 mm

- Thickness 200 μm ± 30 μm

- Front 1.5 ± 0.1 mm busbar (silver)

- Silicon nitride antireflection coating

- Back 3.0 mm continuous soldering pads (silver)

- Back surface field (aluminum)

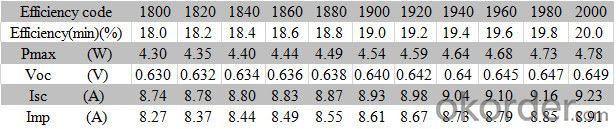

Electric performance parameters

- Testing conditions: 1000 W/m2, AM 1.5, 25 °C, Tolerance: Efficiency ± 0.2% abs., Pmpp ±1.5% rel.

- Imin : at 0.5 V

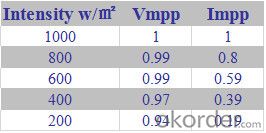

Light Intensity Dependence

Soldering Ability

- Peel Strength: > 1.0 N/mm (Pull soldered ribbon from busbar in 5 mm/s of 180°)

Dimension Figure

Quick Response

- Any time and anywhere, reply clients' email and solve all problems happen in the work at the first time.

- Remove clients doubts and offer the best solution at the first time.

- Give our clients the lastest news of the photovoltaic, update the newest stock informtion.

Production and Quality Control

- Precision cell efficiency sorting procedures

- Stringent criteria for color uniformity and appearance

- Reverse current and shunt resistance screening

- ISO9001,ISO14001 and OHSAS 18001,TUV Certificated

FAQ:

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangsu

2. Q: How can I visit your factory?

A: Before you visit,please contact us.We will show you the route or arrange a car to pick you up.

3. Q: Do you provide free sample?

A: Commenly we provide paid sample.

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we accept it.And need an Authorization Letter from you.

5. Q: Do you accept custom design on size?

A: Yes, if the size is reasonable.

6. Q: How can I be your agent in my country?

A: Please leave feedback. It's better for us to talk about details by email.

7. Q: Do you have solar project engineer who can guide me to install system?

A: Yes, we have a professional engineer team. They can teach you how to install a solar system.

- Q:What is the expected lifespan of a solar silicon wafer in a solar panel?

- The expected lifespan of a solar silicon wafer in a solar panel is typically around 25 to 30 years.

- Q:Are solar silicon wafers affected by power grid fluctuations?

- No, solar silicon wafers used in solar panels are not directly affected by power grid fluctuations. Solar panels generate electricity through the photovoltaic effect, which relies on sunlight to produce electricity. The power grid fluctuations, typically caused by variations in demand or supply, do not directly impact the functioning or efficiency of solar silicon wafers. However, solar panels can be indirectly affected by power grid fluctuations if the grid is unstable or experiences sudden voltage changes, which may affect the overall performance of the solar power system.

- Q:How to make monocrystalline silicon solar panels? Begged: specific steps

- Wafer inspectionSilicon wafer is the carrier of solar cell, the quality of silicon wafer directly determines the conversion efficiency of solar cell. This procedure is mainly used to measure the technical parameters of silicon wafer on line. These parameters mainly include the surface roughness of the silicon wafer, the lifetime of the minority, the resistivity, the P/N type and the micro crack. The device is divided into four parts: automatic loading and unloading, silicon wafer transmission, system integration part and. The silicon photovoltaic detector on the silicon wafer surface roughness were detected, and the size and appearance of diagonal parameter detection chip; micro crack detection module is used to detect silicon micro cracks; another two detecting module, a [url=] module [/url] online test mainly test wafer resistivity and wafer type, on the other a module for lifetime test wafer. The detection of the diagonal and micro cracks of the silicon wafer is needed before the sub lifetime and resistivity measurement. Wafer inspection equipment can automatic loading and unloading, and substandard products in a fixed position, so as to improve the detection accuracy and efficiency.

- Q:The higher the resistivity of silicon wafers, the better?!!! 1 experts please answer me!

- Low resistivity is helpful to improve the opening pressure, high resistivity and help to improve the short-circuit current, the best match between the two is about 1 -3! Own understanding!

- Q:How does the temperature affect the performance of a solar silicon wafer?

- The temperature directly affects the performance of a solar silicon wafer. Higher temperatures reduce the efficiency of the solar cell, resulting in lower power output. This is because the increase in temperature causes an increase in electron-hole recombination, reducing the overall number of electrons available for current generation. Thus, maintaining lower temperatures is crucial to optimize the performance and efficiency of solar silicon wafers.

- Q:Specific kind of industry to use the reference price is what?!I have a ton of silicon chips, want to sell, do not know what the price, do not know what the company needs!

- List of productsPolycrystalline silicon ingot (Figure) silicon wafer (Figure)Battery (Figure) aluminum alloy color frame components (Figure)Epoxy resin encapsulation component photoelectric curtain wall component (all glass component)Solar lawn lamp (map) solar garden lamp (Figure)Solar communication power supply (map) solar mobile power supply (map)

- Q:What is the role of solar silicon wafers in building-integrated photovoltaics?

- Solar silicon wafers play a crucial role in building-integrated photovoltaics (BIPV) as they are the key component used to convert sunlight into electricity. These wafers are made of high-purity silicon and are responsible for capturing and absorbing solar energy. They are then wired together to form solar cells, which are integrated into the building's architecture, such as rooftops or facades. The solar silicon wafers essentially act as the building blocks of BIPV systems, enabling the generation of clean and renewable energy directly from sunlight.

- Q:Can solar silicon wafers be used in disaster response vehicles?

- Yes, solar silicon wafers can be used in disaster response vehicles. They can be used to harness solar energy and power various systems and equipment in these vehicles, providing a sustainable and reliable source of power during emergency situations.

- Q:How does the efficiency of a solar silicon wafer change with temperature?

- The efficiency of a solar silicon wafer typically decreases with increasing temperature. This is because the electrical conductivity of silicon increases with temperature, leading to higher recombination rates and reduced electron-hole collection efficiency. Additionally, higher temperatures can cause an increase in the bandgap, resulting in a decrease in the number of photons absorbed by the wafer. These factors contribute to a decrease in the overall efficiency of the solar silicon wafer as temperature rises.

- Q:Pure curiosity why silicon wafer is round

- Major manufacturers are trying to expand the cross-sectional area of monocrystalline silicon, not just to cut more wafers per wafer...It's a waste of a lot of material if it's easy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mono Solar Cells156mm*156mm in Bulk Quantity Low Price Stock 20.0

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords