hollow plastic construction formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

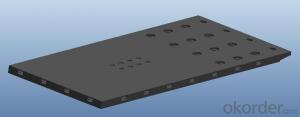

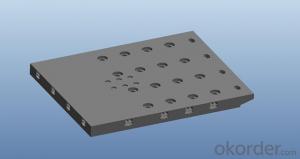

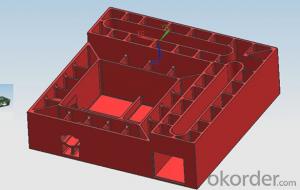

PP Hollow Concrete Template:

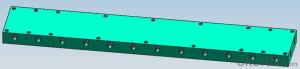

Standard measure:1830*915*15mm,other size can be customized.

National Patent,Authority Attestation,Quality Assurance.

Wear-resisting,Corrosion resistance.

Nonabsorbent,nondeformable.

Environmental protection.

Recycling and reuse,repeated times more than 30 times.

Small deformation, high stiffness, bearing capacity is strong.

Can be processing, can be saw, plane, can be nailed.

One smooth surface,and one decorative pattern surface.

Smooth surface can make the concrete tamping body smooth and level off, without secondary plaster, save material and time, reduce the cleaning and maintenance cost, used in damp environment such as basement and bridge piers.

Decorative Pattern is helpful to combine with plaster layer, special diffuse reflection effect of the light, avoid strong light reflection.

Comprehensive use of cost :Kaili Lang PP hollow concrete template than ordinary wooden template can save more than 30%.

Item | Kaili Lang PP Hollow Concrete Template (A) | Ordinary Wooden Template (B) | Ordinary Bamboo Template (C) | Comparative advantage |

Thickness(mm) | 15 | 15 | 15 | Equal |

Weight(kg/㎡) | ≦10 | 11.6 | 12.7 | A better than B\C |

Repeated Times | 30-40 | 3-5 | 4-7 | A better than B\C |

Impact Strength | High | Low | Low | A better than B\C |

Range of Application | Wall\Pillar\Girder \ Slate\Bridge | Wall\Pillar\Girder\Slate | Wall\Pillar\Girder\Slate | A better than B\C |

Surface Quality | Flat and Glabrous | Roughness | Roughness | A better than B\C |

Efficiency of Construction | High | Low | Low | A better than B\C |

Abrasive Resistance | Antiwear | No Wear | No Wear | A better than B\C |

Recyclable | Yes | No | No | A better than B\C |

Maintenance Charge | None | A Release Agent is required | A Release Agent is required | A better than B\C |

Corrosion Resistance | Acid and Alkali Resistant | No | No | A better than B\C |

Drop Test(10m) | Not Broken | Broken | Broken | A better than B\C |

Hydroscopicity & Deformation | Nonabsorbent & Nondeformable | Water Absorption & Deformation | Water Absorption & Deformation | A better than B\C |

Environmental Pollution | No Pollution | Pollution | Pollution | A better than B\C |

Advantages of hollow plastic construction templates

Stable product quality

The new hollow plastic construction templates produced by Kaili Lang Technology have canonical size, less deformation, high stiffness, strong bearing capacity, acid/alkali resistance. It will not be deformed after long time’s immersion of water, and can make the quality of architectural structure more stable. Both of architectonic size’s accuracy and the concrete’s qualified rate which adopted by the new hollow plastic building construction template system are above the national standard.

Energy-Efficient Innovation

The new hollow plastic construction template produced by Kaili Lang Technology adopts different surface treatment technology which can make templates have smooth and pattern side in the same time. It can meet fair-faced decoration requirement and save the cost of two coat work if we use smooth side during our construction; If we use pattern side, we can not only met the fair-faced decoration requirement, but also reduced the thickness of floated coat because the pattern increased the binding between concrete and floated coat. It simplified the construction difficulty and made assembly and disassembly of components more easy and simple. Thus the technical requirement for workers is not high, and there’s no dependence of equipments. There’s also no need of brushing release agent, which has greatly improved the efficiency, shortened the construction period, reduced the manpower cost and saved the material cost.

Economic benefit

The new hollow plastic construction templates produced by Kaili Lang Technology turnover time can more than 30 times, which reduced 12% work compared to the traditional wood templates. The comprehensive cost can reduced more than 30% and obviously reduced the usage of construction material such as river sand, wood, cement, and reduced the production of construction waste. It have paid an unprecedented role in energy saving and emission reduction.

Social benefit

In present, most templates used in Chinese building engineering are wooden templates. In 2011, wooden templates’ market scale has more than 300 million square meters, which need to cut 16 million trees whose diameter is more than 30cm. It means to use 10,000 hectare to meet the market demand for wood templates. With the continuous increase of building quantity, which also increased at the rate of at least 10%, the massive usage of wooden templates not only destroys forest resources, but the subsequent waste will cause the secondary environmental pollution. The new hollow plastic construction templates produced by Kaili Lang Technology adopt high-tech production process. All product raw materials are from the production and processing of secondary materials. All obsolete templates after clients’ use can be recovered and reused, which means a real energy and environmental revolution.

- Q:I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- You do not explain your product is to open a metal mold or plastic mold, the two mold materials are not the same! I do plastic mold, we mainly use the factory S136 quenching material as a mold material, the slider generally use 718. And you also have the output of the product requirements of the mold, the production will choose a better point of the material.

- Q:Plastic building template where there is an urgent need to solve

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q:How does the concrete on the plastic template remove (already glued to the concrete)

- Water, washed with water, rubbing with things, spend time slowly removed

- Q:Will the plastic building template on the builders really do not use the price is how much price

- Low foaming high strength plastic building template. The template rigid plastic combination, high strength, light weight, impact strength, can be sawable nail can be welded, industrial temperature up to -15 ℃ to 75 ℃ can be applied without cracking. 10 meters high vertical drop does not break, can be used 40 times to 100 times, waste plate can be recycled, more than 30% of the cost savings than the wood template, is the twenty-first century to plastic and wood ideal plastic building template.

- Q:Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- The lower the density of the foam board is easier to deform.Crust foam can be changed to coextrusion foam. General cross-linking or blending halogenation and other methods to improve Vicat. Reduce traction override

- Q:Why the floor is not plastic building materials square wood and template

- Is the plastic strong? The environment on the site you know, throw off how to do, have to find strong and durable.

- Q:Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- The reason why the use of the template is to use the template template is the accuracy of the template, that is, after the mold can be set to ensure that the finished product finished shape regular, flush. While the plastic film version is not damaged, the completion can achieve this requirement. But the crux of the problem is that the biggest weakness of the plastic film is too brittle. Those who have done the work know that when the demolition of the template, the workers removed the template directly down to throw. And this throw to lead to the plastic film version of the broken, it is very difficult to film in the film. This is also the reason why the plastic film from the interview more than 10 years can not always develop the root causes. And then plastic film board in the mold when it is very strenuous, must drill with a drill, or can not die, not convenient construction. This is also a plastic film version can not become a mainstream template and a fatal weakness. The third weakness is its flammability. Construction site of the steel connections are required welding, welding flowers gradually to the plastic film board, at least in its surface to form a deep pit (or even lead to fire), a direct impact on the finished product surface finish and flatness.

- Q:Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- This is mainly to see how the use of workers in the process of operation by standard, 50 times is entirely possible. The use of plastic templates a little bit, the most important thing is to focus on cost savings, integrated plastic template cost is the lowest. But the price is more expensive than the wood template, long-term, large-scale use is cost-effective.

- Q:Who used it, how not universal.

- 4. The product pouring concrete surface smooth, bright as a mirror, to meet the requirements of decorative and decorative water, eliminating the need for secondary plastering process. 5. Turnover times more than 50 times, the template each time the amortization cost is less than 3 yuan, steel frame plastic template turnover times more than 300 6. The material is non-toxic, harmless, pollution-free, 100% recovery, green products The 7. The product acid, alkali, anti-corrosion performance. Product use temperature of -80 ℃ ~ 100 ℃, good weather resistance.

- Q:Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- The general building materials market have to sell, I hope my answer can help you ~

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

hollow plastic construction formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords