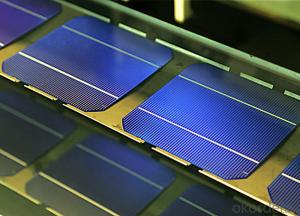

High Current Solar Cell 18.2% Polycrystalline Silicon Solar Cell Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

4 Bus Bars 156*156 17.6% efficiency poly solar cell

PHYSICAL CHARACTERISTICS

Dimension: 156mm x 156mm ± 0.5mm

Wafer Thickeness: 180um+20um and 200um+20um

Front(-) Four 1.2mm silver busbar

Silicon nitride blue anti-reflection coating

Back(+) aluminum back surface field

1.75mm(silver) wide segment soldering pads

Typical Electrical Characteristics

Efficiency | W(Pmpp) | V(Umpp) | A(Impp) | V(Uoc) | A(Isc) |

17.4-17.5 | 4.234 | 0.517 | 8.231 | 0.622 | 8.759 |

17.5-17.6 | 4.259 | 0.519 | 8.243 | 0.623 | 8.769 |

17.7-17.8 | 4.283 | 0.521 | 8.256 | 0.625 | 8.779 |

17.8-17.9 | 4.307 | 0.523 | 8.268 | 0.626 | 8.788 |

17.9-18.0 | 4.332 | 0.525 | 8.281 | 0.627 | 8.798 |

18.0-18.1 | 4.380 | 0.529 | 8.306 | 0.629 | 8.808 |

18.1-18.2 | 4.405 | 0.531 | 8.318 | 0.632 | 8.818 |

18.2-18.3 | 4.429 | 0.533 | 8.331 | 0.633 | 8.837 |

18.3-18.4 | 4.453 | 0.535 | 8.344 | 0.634 | 8.847 |

18.4-18.5 | 4.478 | 0.537 | 8.356 | 0.636 | 8.856 |

18.5-18.6 | 4.502 | 0.539 | 8.369 | 0.637 | 8.866 |

Efficiency | W(Pmpp) | V(Umpp) | A(Impp) | V(Uoc) | A(Isc) |

20.90-21.00 | 5.06 | 0.557 | 9.007 | 0.653 | 9.688 |

20.80-20.90 | 5.04 | 0.556 | 9.062 | 0.652 | 9.683 |

20.70-20.80 | 5.02 | 0.554 | 9.055 | 0.651 | 9.684 |

20.60-20.70 | 4.99 | 0.552 | 9.033 | 0.651 | 9.672 |

20.50-20.60 | 4.97 | 0.550 | 9.002 | 0.650 | 9.673 |

20.40-20.50 | 4.94 | 0.548 | 9.012 | 0.649 | 9.674 |

20.30-20.40 | 4.92 | 0.546 | 9.009 | 0.649 | 9.655 |

20.20-20.30 | 4.89 | 0.543 | 9.012 | 0.648 | 9.634 |

20.10-20.20 | 4.87 | 0.541 | 8.998 | 0.648 | 9.617 |

20.00-20.10 | 4.85 | 0.540 | 8.977 | 0.647 | 9.600 |

*Data under standard testing conditional (STC):1,000w/m2,AM1.5, 25°C , Pmax:Positive power tolerance.

3 Bus Bars 156*156 17.4% efficiency poly solar cell

Dimension: 156 mm x 156 mm ± 0.5 mm

Wafer Thickeness: 156 mm x 156 mm ± 0.5 mm

Typical Electrical Characteristics:

| Efficiency code | 1660 | 1680 | 1700 | 1720 | 1740 | 1760 | 1780 | 1800 | 1820 | 1840 | 1860 |

| Efficiency (%) | 16.6 | 16.8 | 17.0 | 17.2 | 17.4 | 17.6 | 17.8 | 18.0 | 18.2 | 18.4 | 18.6 |

| Pmax (W) | 4.04 | 4.09 | 4.14 | 4.19 | 4.23 | 4.28 | 4.33 | 4.38 | 4.43 | 4.48 | 4.53 |

| Voc (V) | 0.612 | 0.615 | 0.618 | 0.621 | 0.624 | 0.627 | 0.629 | 0.63 | 0.633 | 0.635 | 0.637 |

| Isc (A) | 8.42 | 8.46 | 8.51 | 8.56 | 8.61 | 8.65 | 8.69 | 8.73 | 8.77 | 8.81 | 8.84 |

| Imp (A) | 7.91 | 7.99 | 8.08 | 8.16 | 8.22 | 8.27 | 8.33 | 8.38 | 8.43 | 8.48 | 8.53 |

* Testing conditions: 1000 W/m2, AM 1.5, 25 °C, Tolerance: Efficiency ± 0.2% abs., Pmpp ±1.5% rel.

* Imin : at 0.5 V

Production:

Package:

FAQ:

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangsu

2. Q: How can I visit your factory?

A: Before you visit,please contact us.We will show you the route or arrange a car to pick you up.

3. Q: Do you provide free sample?

A: Commenly we provide paid sample.

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we accept it.And need an Authorization Letter from you.

5. Q: Do you accept custom design on size?

A: Yes, if the size is reasonable.

6. Q: How can I be your agent in my country?

A: Please leave feedback. It's better for us to talk about details by email.

7. Q: Do you have solar project engineer who can guide me to install system?

A: Yes, we have a professional engineer team. They can teach you how to install a solar system.

- Q:What are the different types of solar silicon wafers available?

- The different types of solar silicon wafers available include monocrystalline, polycrystalline, and thin-film. Monocrystalline wafers are made from a single crystal structure, making them highly efficient but more expensive. Polycrystalline wafers are made from multiple crystal structures and are slightly less efficient but more affordable. Thin-film wafers are made by depositing a thin layer of silicon on a substrate and offer flexibility and lower production costs, but they have lower efficiency compared to crystalline wafers.

- Q:Can solar silicon wafers be used in solar-powered drones?

- Yes, solar silicon wafers can be used in solar-powered drones. These wafers are commonly used in the production of solar cells and can efficiently convert sunlight into electricity. Solar-powered drones can utilize these wafers to generate the required energy for their operation, allowing them to fly for extended periods without relying on traditional fuel sources.

- Q:Are there any regulations or standards for solar silicon wafers?

- Yes, there are regulations and standards for solar silicon wafers. These standards are established by various organizations such as the International Electrotechnical Commission (IEC) and the American Society for Testing and Materials (ASTM). These standards ensure the quality, efficiency, and reliability of solar silicon wafers, covering factors such as dimensions, electrical properties, and material purity. Compliance with these regulations and standards is crucial for the solar industry to maintain consistency and facilitate widespread adoption of solar technology.

- Q:Are solar silicon wafers affected by voltage fluctuations?

- Yes, solar silicon wafers can be affected by voltage fluctuations. Fluctuations in voltage can impact the performance and efficiency of solar panels, as they rely on a stable and consistent voltage to generate electricity. Variations in voltage can cause fluctuations in current, which can lead to reduced power output or even damage to the solar cells. Therefore, it is important to ensure a stable and well-regulated voltage supply for optimal performance of solar silicon wafers.

- Q:What is the role of anti-reflective coating on solar silicon wafers?

- The role of anti-reflective coating on solar silicon wafers is to minimize the amount of reflected sunlight, thereby increasing the amount of light that can be absorbed by the solar cells. This coating helps to improve the overall efficiency of the solar panels by allowing more light to pass through and be converted into electricity.

- Q:What is the role of light trapping in solar silicon wafers?

- The role of light trapping in solar silicon wafers is to increase the absorption of sunlight within the wafer, thereby enhancing the overall efficiency of the solar cell. By incorporating light trapping structures or techniques, such as textured surfaces or anti-reflective coatings, more light is effectively captured and confined within the wafer, allowing for a greater number of photons to be converted into electricity. This improves the performance of the solar cell by maximizing the utilization of available sunlight.

- Q:How are solar silicon wafers protected from fire or overheating?

- Solar silicon wafers are protected from fire or overheating through a combination of design features and safety measures. First, the solar panels themselves are typically made with non-flammable materials, such as tempered glass, to minimize the risk of fire. Additionally, the wafers are often encapsulated in a protective layer or surrounded by an insulating material to provide thermal insulation and prevent overheating. Furthermore, solar panels are designed with heat dissipation mechanisms, such as ventilation or cooling systems, to regulate temperatures and prevent excessive heat buildup.

- Q:It is said that monocrystalline silicon, polycrystalline silicon wafer cutting requirements and problems are still quite a lot of

- During the cutting process, the wafer quality and rate of finished products played a major role in the grain type, viscosity of silicon carbide powder cutting fluid and particle size, the viscosity of mortar, mortar flow, steel wire speed and wire tension and workpiece feed speed.TTV: and TTV stria stria and is a headache in the wafer processing, from time to time there will be a knife, impossible to guard against. TTV is when the knife into the line, and is easy to appear in the time line bow.

- Q:How are solar silicon wafers handled and stored to prevent contamination?

- Solar silicon wafers are typically handled and stored in a cleanroom environment to prevent contamination. Cleanroom facilities are designed to minimize the presence of particles and other contaminants in the air, ensuring the wafers remain clean and free from impurities. Additionally, personnel working in cleanrooms wear specialized cleanroom garments, including gloves, masks, and coveralls, to prevent any potential contamination from their bodies. The wafers are typically stored in sealed containers or trays, further protecting them from airborne contaminants and potential damage. Stringent procedures and protocols are followed to maintain a controlled environment and minimize the risk of contamination throughout the handling and storage processes.

- Q:How does the efficiency of a solar silicon wafer change with snow cover?

- The efficiency of a solar silicon wafer decreases with snow cover. Snow acts as an insulator, preventing sunlight from reaching the wafer and reducing its ability to generate electricity. Additionally, snow can also cause shading on the surface of the wafer, further reducing its efficiency.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Current Solar Cell 18.2% Polycrystalline Silicon Solar Cell Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords