Mapei Waterproofing Membrane

Mapei Waterproofing Membrane Related Searches

Wavy Plastic Roofing Copper Roofing Material Concrete Foundation Waterproofing Membrane Industrial Roofing Spray Foam Roofing Waterproofing Concrete Floors Material Waterproofing Spray Commercial Roofing Systems Shake Roofing Materials Synthetic Felt RoofingHot Searches

Geotextile Membrane Suppliers Bituminous Waterproofing Membrane Manufacturers Waterproofing Company Names Pvc Roofing Sheets Price India Pvc Roofing Sheets Price Plastic Flower Buckets Wholesale Wholesale Plastic Hanging Baskets Plastic Planter Liners Wholesale Grp Roofing Prices Geotextile Membrane Suppliers Breathable Roofing Felt Prices Roofing Tar Prices Bitumen Roofing Felt Suppliers Roofing Resin Suppliers Bituminous Waterproofing Membrane Manufacturers Waterproofing Company Names Grp Roofing Prices Geotextile Membrane Suppliers Breathable Roofing Felt Prices Roofing Tar PricesMapei Waterproofing Membrane Supplier & Manufacturer from China

Okorder.com is a professional Mapei Waterproofing Membrane supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Mapei Waterproofing Membrane firm in China.Hot Products

FAQ

- Waterproofing membranes are generally resistant to salt damage, as they are specifically designed to create a barrier against moisture and water infiltration, offering protection against saltwater as well. Saltwater can be highly corrosive and cause harm to different materials, but waterproofing membranes are typically constructed using materials that can withstand the corrosive effects of salt. These membranes often consist of reinforced PVC, modified bitumen, or EPDM rubber, all of which have proven their durability and reliability in saltwater environments. In fact, waterproofing membranes are commonly used in areas like basements, swimming pools, and marine structures, where they are regularly exposed to saltwater. Thus, it can be concluded that waterproofing membranes are generally resistant to salt damage and effectively shield against saltwater infiltration.

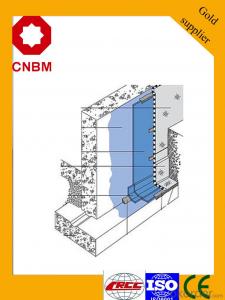

- Yes, a waterproofing membrane can be used for below-grade parking structures. Waterproofing membranes are commonly used in construction to prevent the ingress of water and protect structures from water damage. In the case of below-grade parking structures, which are underground or partially underground, there is a higher risk of water infiltration due to the surrounding soil and groundwater. Waterproofing membranes are applied to the exterior surfaces of the structure, creating a barrier that prevents water from seeping through the walls and floors. These membranes are typically made of materials such as bitumen, rubberized asphalt, PVC, or polyurethane, which are highly resistant to water penetration. Additionally, some membranes may also have additional properties like crack-bridging capabilities or protection against chemicals or gases. It is important to consult with a qualified engineer or waterproofing specialist to determine the most suitable membrane for a specific below-grade parking structure, taking into consideration factors such as soil conditions, hydrostatic pressure, and local building codes.

- Yes, a waterproofing membrane can be used for sealing pipe penetrations. Waterproofing membranes are specially designed to create a barrier against water intrusion and can effectively seal various types of penetrations, including pipes. They are commonly used in construction projects to prevent water leaks and damage. By applying the waterproofing membrane around the pipe penetration, it creates a watertight seal that prevents water from entering or escaping through the opening. This helps to maintain the integrity of the building envelope and protect against potential water-related issues, such as leaks, mold growth, and structural damage. Additionally, waterproofing membranes are often flexible, allowing them to adapt to the shape and size of the pipe penetration, ensuring a secure and durable seal.

- Yes, a waterproofing membrane can be used for retaining walls. Retaining walls are structures designed to hold back soil or water, and it is essential to prevent water penetration to avoid potential damage or structural failure. Waterproofing membranes are commonly used to provide a barrier against water infiltration, thereby protecting the retaining wall and ensuring its stability over time. These membranes are typically made of materials like rubber, PVC, or bituminous compounds, and they are installed on the inner side of the retaining wall to prevent water from seeping through. Additionally, some waterproofing membranes also offer additional benefits such as resistance to root penetration, UV protection, and flexibility to accommodate movement in the retaining wall. However, it is important to note that the specific type of waterproofing membrane used should be selected based on factors such as the type of retaining wall, the level of water pressure, and local climate conditions. Consulting with a professional engineer or contractor is recommended to ensure the appropriate waterproofing solution for your particular retaining wall project.

- Yes, a waterproofing membrane can be tiled over. Tiling over a waterproofing membrane provides an additional layer of protection against water damage and helps create a durable and moisture-resistant surface.

- Waterproofing membranes effectively combat mold and mildew by acting as a barrier against water infiltration. This barrier reduces moisture, which is essential for mold and mildew growth. By sealing the surface, these membranes prevent water intrusion and the subsequent moisture buildup that fosters mold and mildew formation. Some waterproofing membranes even have anti-microbial properties that specifically hinder the growth of mold and mildew. Nevertheless, it is crucial to remember that in order to achieve long-term prevention, proper building ventilation and maintenance are also imperative, despite the significant risk reduction provided by waterproofing membranes.

- Concrete block walls can indeed benefit from the use of waterproofing membranes. It is actually quite common and highly advised to employ such membranes on concrete block walls in order to ward off water infiltration and potential moisture-related harm. These membranes are specifically engineered to establish a barrier against water and can be effectively applied to either the exterior or interior surface of the concrete block walls. In doing so, they furnish an added layer of safeguarding, thereby preventing moisture from penetrating the walls and causing issues such as the growth of mold, efflorescence, and the deterioration of the concrete blocks themselves. By opting for the utilization of waterproofing membranes, you can effectively ensure the long-lasting resilience and durability of your concrete block walls.

- A waterproofing membrane typically handles construction joints by providing a seamless and continuous barrier that seals and protects the joints from water infiltration. It is applied over the construction joint and adheres to both sides, ensuring no gaps or openings for water to enter. This helps to prevent water damage and maintain the structural integrity of the building or structure.