Roof EPDM Waterproofing Membrane Width from 1.2mm to 2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM waterproofing membrane

1. Brief Introduction:

This waterproof membrane is made from ternary ethylene-propylene rubber. Weadopts the world advanced equipment of cold feeding extrusion and continuous valcanization technology.

With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

2. Characters:

1)Good flexibility, creep properties and malleability, and the superior adapting ability to the deformation of the primary stress generated.

2). Tight adhesion between waterproof layer and basic layer, no channeling water. Having self healing ability after piercing.

3).Operation without heating. And possessing the reliability of pasting by itself with super strong connection of sheet materialand adhesion of same base.

4). Convenient and safe operation, no pollution to the environment.

3. Application:

1),Roofs, Basement, Toilet

2),Industrial and civil building waterproofing

3),Geosynthetic liner for swimming pool, channels, irrigation system

4),Especially suit for projects with high requirements in durability, anti-corrosion anddeformation

4. Package and Storage:

Each Roll with one plastic bag with or without pallets.

Keep in dry and ventilated place. Avoid shining and raining. Height of stack not more than 5 layers. Shelf life:12 months.

5. Specification:

Type | EPDM Waterproof Rubber Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

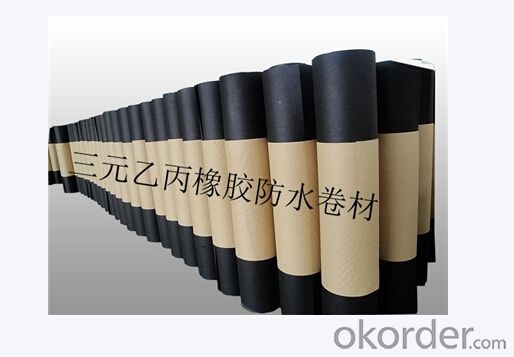

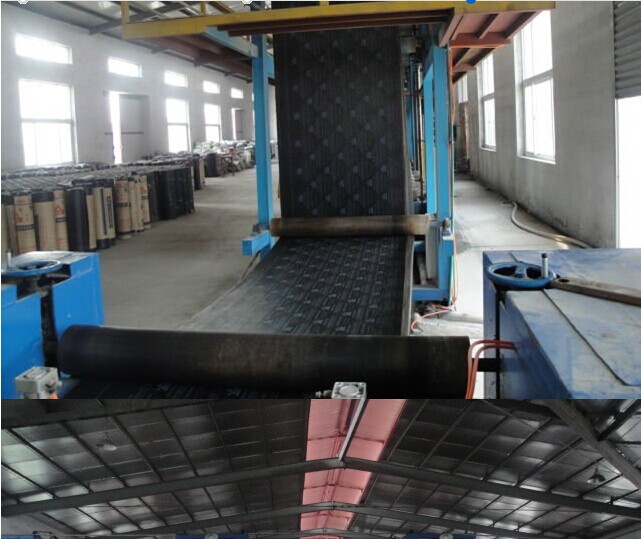

5. Some photos:

- Q:Are waterproofing membranes suitable for tunnels?

- Tunnels can benefit from the use of waterproofing membranes. These structures often face significant water pressure from the surrounding soil and groundwater, making them susceptible to water entering. Waterproofing membranes are specifically designed to create a protective barrier that prevents water infiltration into the tunnel. These membranes are typically crafted from durable materials like bitumen, PVC, or EPDM rubber. These materials possess a resistance to water penetration, making them ideal for the task. Once applied to the tunnel walls and ceiling, they form a continuous and impermeable layer that effectively keeps the tunnel dry. Additionally, the membranes are flexible, allowing them to adjust to any movement or settlement within the tunnel while maintaining their waterproofing integrity. Apart from their water-blocking capabilities, these membranes offer other advantages for tunnels. They can shield the structure from corrosion caused by water and chemicals, thereby prolonging the tunnel's lifespan. Furthermore, they can improve the indoor air quality by preventing the growth of mold and mildew, which tend to thrive in damp environments. Moreover, waterproofing membranes can be tailored to suit the specific conditions of different tunnels. For instance, in tunnels exposed to high levels of hydrostatic pressure, reinforced membranes with greater tensile strength can be used to withstand the additional stress. Similarly, tunnels that prioritize fire safety can utilize membranes with enhanced fire resistance properties. In conclusion, waterproofing membranes provide a dependable and efficient solution for ensuring the durability, safety, and longevity of tunnels. By serving as a robust barrier against water ingress, they effectively safeguard these structures.

- Q:Can a waterproofing membrane be used in historic buildings?

- Yes, a waterproofing membrane can be used in historic buildings. However, it is important to consider the specific needs and requirements of the building. The use of a waterproofing membrane should be carefully assessed and integrated into the building's preservation and conservation plans to ensure compatibility with its historic fabric and materials. Professional advice and expertise should be sought to ensure the appropriate selection and installation of the waterproofing membrane without compromising the building's historic integrity.

- Q:Are waterproofing membranes suitable for bridge abutments?

- Yes, waterproofing membranes are suitable for bridge abutments. These membranes provide an effective barrier against water infiltration, protecting the abutments from moisture-related damages such as corrosion, deterioration, and leakage. They help extend the lifespan of the bridge and ensure its structural integrity.

- Q:Can a waterproofing membrane be used on concrete surfaces?

- Concrete surfaces can indeed benefit from the application of a waterproofing membrane. These membranes are frequently employed to safeguard concrete constructions, such as basements, foundations, and roofs, against water-related harm. Their purpose is to establish a barrier that prevents water from infiltrating the concrete surface. By doing so, they aid in averting the accumulation of moisture, the growth of mold, and the deterioration of the concrete. Furthermore, these waterproofing membranes can furnish supplementary defense against chemicals, UV rays, and other environmental elements. To accomplish the desired waterproofing outcomes, it is crucial to ensure that the membrane is properly installed and compatible with the specific concrete surface.

- Q:Can a waterproofing membrane be applied in cold weather?

- Yes, a waterproofing membrane can be applied in cold weather. However, it's important to consider the specific product's instructions and limitations, as some membranes may have temperature requirements for proper installation. Additionally, cold weather conditions may affect the curing time of the membrane, so it's crucial to follow the manufacturer's guidelines to ensure a successful application.

- Q:Can waterproofing membranes be used on balconies?

- Yes, waterproofing membranes can be used on balconies. Waterproofing membranes are specifically designed to provide a protective barrier against water penetration, making them an ideal solution for balconies that are exposed to weather elements such as rain, snow, and moisture. These membranes are typically applied to the surface of the balcony to create a seamless, watertight seal, preventing water from seeping through and causing damage to the underlying structure. The use of waterproofing membranes on balconies helps to extend their lifespan, reduce maintenance costs, and ensure the overall durability and functionality of the balcony.

- Q:Are waterproofing membranes resistant to chemical solvents?

- Yes, waterproofing membranes are generally resistant to chemical solvents. Most waterproofing membranes are designed to withstand exposure to various chemicals, including solvents. They are specifically formulated to provide a barrier against moisture and also protect against damage from chemical exposures. This resistance to chemical solvents is an important feature of waterproofing membranes, as it ensures their durability and effectiveness in a wide range of applications, such as in construction, roofing, and below-grade waterproofing. However, it is important to note that the specific resistance of a waterproofing membrane to chemical solvents can vary depending on the type and brand of membrane used, so it is always recommended to consult the manufacturer's guidelines for specific information on chemical resistance.

- Q:Can a waterproofing membrane be used for a swimming pool deck?

- Yes, a waterproofing membrane can be used for a swimming pool deck. Waterproofing membranes are designed to provide a barrier against water infiltration, which makes them suitable for protecting the pool deck from water damage and ensuring its longevity.

- Q:Are there any specific fire safety considerations for using a waterproofing membrane?

- Yes, there are specific fire safety considerations for using a waterproofing membrane. It is important to ensure that the membrane used is fire-resistant and complies with relevant fire safety codes and regulations. Additionally, proper installation techniques and fire barriers should be implemented to prevent the spread of flames and smoke in case of a fire. Regular maintenance and inspections are also necessary to ensure the membrane's fire safety integrity is maintained throughout its lifespan.

- Q:Is a waterproofing membrane resistant to algae or moss growth?

- A waterproofing membrane is usually resistant to the growth of algae or moss. Its purpose is to form a barrier against water infiltration, preventing moisture from seeping into the underlying structure. These membranes are typically composed of materials that are not favorable for the growth of algae or moss, such as synthetic polymers or rubberized compounds. Furthermore, they are often treated with additives that hinder the growth of organic matter, including algae or moss. Nevertheless, it is crucial to acknowledge that if the membrane is consistently exposed to moisture or damp conditions over time, it may become a breeding ground for algae or moss. Therefore, it is important to regularly maintain and clean the waterproofing membrane to ensure its longevity and effectiveness.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roof EPDM Waterproofing Membrane Width from 1.2mm to 2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords