Butterfly Valve DN200 Turbine Type Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

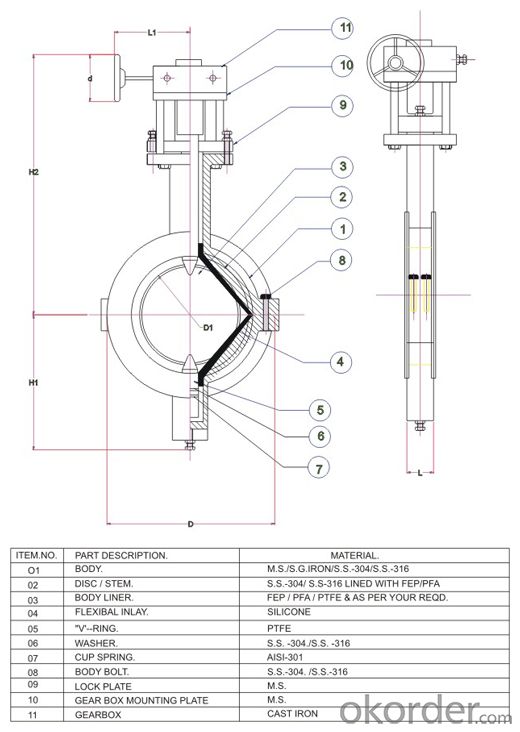

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:How do you draw the butterfly valve in the engineering drawing?

- Butterfly valve there are many kinds of painting, according to the design institute out of the icon, below we together to understand the icon, which has the butterfly drawing.

- Q:What do you mean, handle, butterfly valve, hard back and soft back?

- The butterfly valve of the handle butterfly valve is installed in the direction of the diameter of the pipe. In the butterfly valve body cylindrical channel, the disc shaped butterfly plate revolves around the axis, the rotation angle is between 0 degrees -90 degrees, when rotates to 90 degrees, the valve is fully open. This valve is mounted horizontally.Butterfly valve has an elastic seal and metal seal two types of seals. Resilient sealing valve. The sealing ring can be mounted on the valve body or attached to the periphery of the disc.The hard back is the metal seal, and the soft back is the elastic seal.

- Q:Butterfly valve structure and working principle

- The clip type butterfly valve is connected with the two pipe flange with a stud bolt. The flange type butterfly valve is provided with a flange on the valve, and bolts are used to connect the flanges at the ends of the valve to the pipe flange.

- Q:Butterfly valve D71X-1.6C, DN50, there is no difference between C and no C? What do you mean by "concrete"?

- D stands for butterfly valve. 71 represents the clamp type, X represents the sealing surface material, and 16 represents the valve to bear the pressure 1.6MPA, C position is the valve body material code, omitted to represent gray cast iron valve; C represents the valve body material is carbon steel.

- Q:Not the cold and hot water shut off valves. The one with a tiny handle and it looks like a T. what does it do? should I mess with it?

- Well definitely should not mess with it, especially if you do not know exactly what it is and more important what it controls. If not water, then it could possibly be the shut off for a near by gas appliance. It would help if you described the size and color of the pipe. Maybe you could try to trace it , where does it come from and where does it go to ?

- Q:Butterfly valve, two-way pressure and one-way pressure what is the difference?

- One way sealing butterfly valve is the front of the butterfly valve. When it closes, it must face the direction of the medium. The medium flows only in one direction, and the arrow on the valve body indicates the direction of the flow direction of the medium. Attention should be paid to the flow direction of the medium during installation. Two way butterfly valve is butterfly plate can face or back to the media flow direction, installation without attention to medium flow direction, in the valve body also does not indicate the direction of the medium flow arrow. Two way sealing butterfly valve stem force is greater than one-way butterfly valve stem. Design, the same diameter, pressure butterfly valve, two-way sealing butterfly valve rod diameter than one-way sealing butterfly valve stem diameter.

- Q:What's the material of the butterfly valve seat?

- Tianjin saide valve limited company can provide all kinds of valve seat material for the majority of users: white food gum X1 - X2 - X3 - Hypa EPDM rubber X4 rubber X5 - resistant rubber X6 - fluorine rubber X7 - heat resistant ethylene propylene rubber X9 silicone rubber and PTFE F4.

- Q:Butterfly valve common faults and treatment methods?

- Three, summary:Only familiar with every detail of circulating water pump outlet valve and butterfly valve equipment, timely and thorough maintenance and strict debugging, to ensure the safety and reliability of equipment operation, to ensure the healthy and orderly operation of equipment.

- Q:What's the difference between turbine butterfly valve and manual butterfly valve?

- Butterfly (Manual butterfly) butterfly plate installed in the direction of the diameter of the pipe. In the butterfly valve body cylindrical channel, the disc shaped disc rotates around the axis. The angle of rotation is between 0 and -90 degrees. When rotating to 90 degrees, the valve is fully open.Butterfly valve structure is simple, small size, light weight, only by a few parts. The utility model can be rapidly opened and closed only by rotating 90 DEG, the operation is simple, and the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the butterfly plate thickness is the only resistance when the medium passes through the valve body, so the pressure drop produced by the valve is very small, so the flow control characteristic is better. Butterfly valve has an elastic seal and metal seal, two types of seals. Resilient sealing valve. The sealing ring can be mounted on the valve body or attached to the periphery of the disc.

- Q:I was wondering if someone could tell me the manufacturing date on this aircraft engine valve.

- Wow Hannah! That's a cool find for sure! It appears to be possibly a valve for a radial aircraft engine as it looks very similar to ones i've seen used in Pratt+Whitney R3350's etc. It looks like it could probably date to the 1940's up thru the 1950's. Look for a Part Number stamped on the valve or on the box. After WW2 there were all kinds of manufacturers making parts for airplanes. Many were gobbled up by competitors, converted to manufacturing other products or went out of business altogether. However, a few did hang on....and I think this may be what has become of Thompson Aircraft today.... Thompson Aerospace, Inc 22431 Antonio Parkway B160-102 Rcho Sta Marg, CA 92688-2804

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butterfly Valve DN200 Turbine Type Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords