Gate Valve DN350 Non-rising BS5163 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

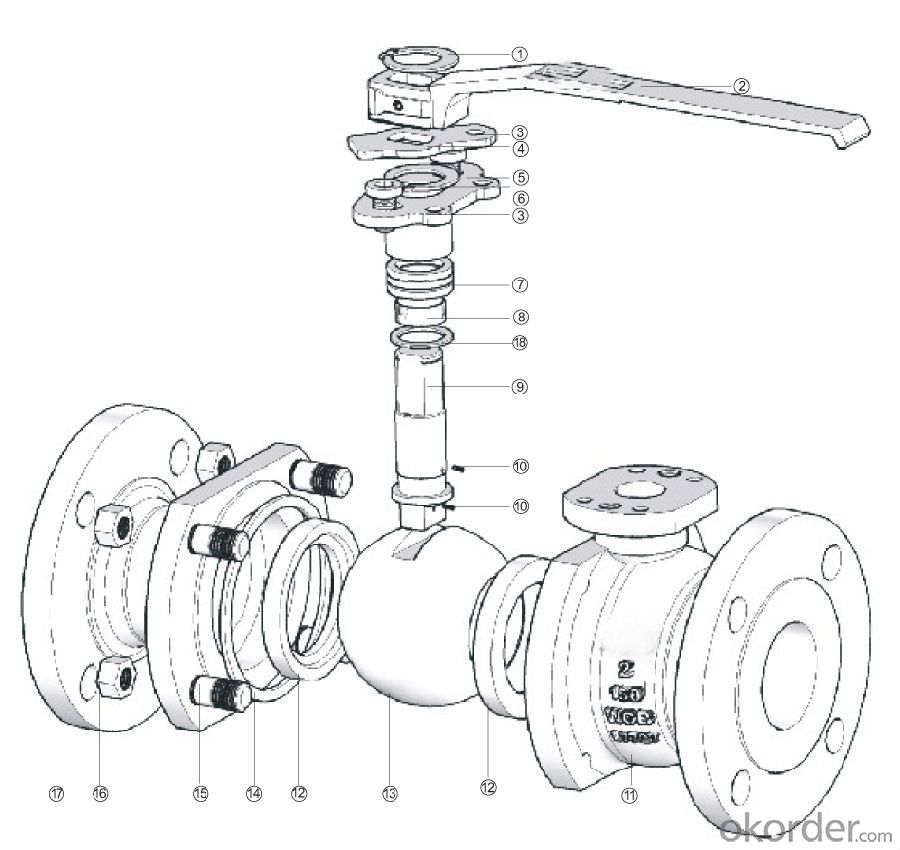

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q:What's the difference between D71X-16 and D71H-16 butterfly valves?

- D71X-16 and D71H-16 butterfly difference is that the cut-off is not the same, the latter is stainless steel seal, corrosion resistance, friction, acid or impurities can be medium fluid. The former is rubber sealed, only through the general temperature of the medium, not acid, with more, you can ask Luoyang crown Ning

- Q:Who can give me a download UG butterfly valve, needle valve, diaphragm valve standard model address, Japanese standard, American Standard.

- Give you the address bar, this is a three-dimensional CAD model library of an online version of the real registered mail, free of charge, there are hundreds of Chinese and foreign manufacturers of the product model is available for download, such as ABB, SMC, FESTO, AIRTAC, CAMOZZI, MISUMI etc..

- Q:What's the difference between a clip on handle butterfly valve and a turbo butterfly valve? Where are they used?

- Depending on the size of the valve and the opening and closing torque, the transmission mode is different (handle or turbine).

- Q:Butterfly valve in the use of the difference? Caliber?

- According to the function and use of the valve and butterfly valve, gate valve, small flow resistance, good sealing performance, the valve plate and the flow direction of the medium is the vertical angle, if the valve is not in place in the valve plate switch, wash medium on the valve plate of the valve plate is easy to fibrillation, according to valve seal damage.Also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the flow of air, water, steam steam, all kinds of corrosive medium, mud, oil, metals and radioactive liquid media and other types of fluid. On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation.

- Q:The flow ratio of area and maximum flow area of the valve is? If it refers to the opening of the valve rotation angle? Butterfly linear closure refers to the butterfly valve at constant angular velocity close? When the change trend of flow is what? These valves problem bothering me for a long time,

- Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis rotation, so as to achieve the opening or closing or adjustment; actuators have electric or pneumatic, and so on, through the transmission device to drive the stem, valve plate rotation;

- Q:Who was the first doctor to discover Pulmonary Valve Stenosis? Also, who was the first doctor to perform surgery for it? Please and thank you for your help.P.S. I have this condition.

- 1761 - Pulmonary valvar or valvular stenosis is one of the more common forms of congenital heart malformations and it has been extensively studied since the original description of pulmonary valve stenosis by John Baptist Morgagni in 1761. 1888 - Tetralogy of Fallot, first characterized by Dr.Etienne Fallot in 1888, is present in about 3000 children born each year in the United States. It is a combination of four heart abnormalities. Dodrill and his colleagues employed it with success for the open correction of a stenotic pulmonary valve in October 1952.

- Q:e.g. a patient with a prosthetic aortic valve and a patient with a prosthetic mitral valve. Also, can you get stenosis of mechanical valves or just tissue grafts?Thanks!

- mechanical okorder /

- Q:I have put a new pressure valve and replaced both thermostat

- If it is not overheating due to a stuck thermostat or bad heating element and you changed the TP valve then it is possible you have a problem with thermal expansion. When water is heated it expands and the more it is heated the more volume it will need to expand. Since the water heater and the piping are not designed to expand the water only has one place to go (well two if count the faucet) and that is out the TP valve. This problem is not uncommon and the solution is to have an expansion tank installed on the hot water heater in the piping near the tank.

- Q:1988 volkswagon cabriolet, rabbit tried mystery oil let sit for a week having trouble with stuck valves even taken a wrenrch to manually unstick. help any suggestions 4 cyclinder car has been sitting up for about 4 years

- The only reason for a stuck valve is if it bent from a thrown timing belt. Sitting 4 years will not cause valves to stick usually, because there is always some oil leakage from the head, that prevents rust. How do you know the valve is stuck? Have you done a compression test, checked the valve clearance? When you say you take a wrench to manually unstick it, it would help to know what you mean, because there is no place to put a wrench that would help unstick a valve that was stuck. You need to tell us much more.

- Q:I did a compression check on my 350 chevy. I have low compression of 175psi on one cylinder.The other seven cylinders range from 195psi to 205psi Could the valves be too tight on the cylinder with 175 psi compression?

- Chev engines have hydraulic lifters, keeping the valves adjusted correctly at all times. 20 lbs isn't much to worry about anyway, but if you want dump a little oil (about a tablespoons worth) into that cylinder and recheck it. If the compression jumps up, then your rings are getting weak. If not, you may have a leaky valve.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gate Valve DN350 Non-rising BS5163 Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products