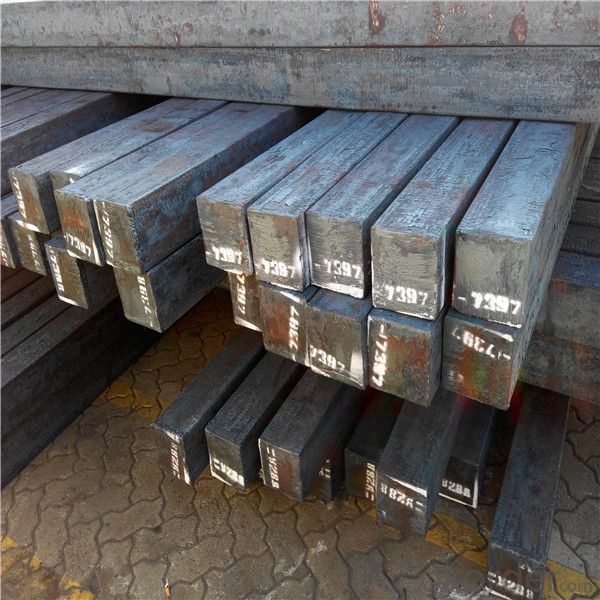

Billet steel from our own mill in good price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15250 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Steel billet

(ingot) by cogging or breakdown of semifinished products, is the raw material of all kinds of steel mill.

Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the

shape of rolled products.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base

building the support foundation pile manufacturing.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q:What are the different surface finishing techniques used for steel billets?

- Some of the different surface finishing techniques used for steel billets include shot blasting, pickling, and grinding. Shot blasting involves propelling abrasive particles at high speeds to remove rust, scale, and other surface contaminants. Pickling is a chemical process that uses acids to remove oxides, scale, and other impurities from the surface of the steel billets. Grinding is a mechanical process that uses abrasive wheels to smooth and polish the surface of the billets, creating a desired finish. These techniques help improve the surface quality and prepare the steel billets for further processing or use.

- Q:How do steel billets contribute to the overall sustainability of a structure?

- There are several ways in which steel billets are crucial for enhancing the overall sustainability of a structure. Firstly, steel is a highly durable material with a long lifespan. This means that structures built with steel billets will have a longer service life and require fewer replacements or repairs. Consequently, the consumption of resources and materials needed for construction is reduced, resulting in minimized waste and conserved energy. Moreover, steel is 100% recyclable, allowing the steel billets to be easily recovered and reused for other purposes at the end of a structure's lifespan. Compared to producing steel from raw materials, recycling steel requires significantly less energy. As a result, greenhouse gas emissions are reduced, and carbon footprints are lower. This approach of a circular economy helps conserve resources and reduces the demand for new steel production, which has a significant environmental impact. Furthermore, steel billets contribute to the overall sustainability of a structure through their strength and versatility. With a high strength-to-weight ratio, steel can support heavy loads with less material, leading to more efficient designs and reduced material consumption. This not only conserves resources but also decreases the carbon emissions associated with the transportation and delivery of steel. Additionally, steel is a non-combustible material, offering structures built with steel billets greater resistance to fires. This enhances the safety and resilience of the structure, reducing the risk of damage or collapse during unforeseen events. Furthermore, the use of steel in structures can contribute to energy efficiency by providing a thermal mass that retains and releases heat, reducing the need for excessive heating or cooling. In conclusion, through their durability, recyclability, strength, and non-combustible properties, steel billets significantly contribute to the overall sustainability of a structure. By incorporating steel into construction, we can minimize waste, conserve resources, reduce carbon emissions, enhance safety, and improve energy efficiency. This ultimately makes structures more environmentally friendly and sustainable in the long run.

- Q:How are steel billets used in the manufacturing of pressure vessel components?

- Steel billets are used in the manufacturing of pressure vessel components by being melted and formed into the desired shape through processes like casting, forging, or extrusion. These billets serve as the raw material for creating various components such as shells, heads, and nozzles, which are then further processed, machined, and assembled to construct the pressure vessel.

- Q:What are the advantages of using steel billets in the oil and gas industry?

- There are several advantages of using steel billets in the oil and gas industry. 1. Strength and Durability: Steel billets are known for their high strength and durability. They can withstand extreme temperatures, pressures, and corrosive environments, making them suitable for use in the oil and gas industry where demanding conditions are common. 2. Resistance to Corrosion: Steel billets are often made from corrosion-resistant alloys or treated with protective coatings to enhance their resistance to corrosion. This is crucial in the oil and gas industry, as it involves the handling of various corrosive substances that can degrade equipment and infrastructure over time. By using steel billets, companies can ensure their equipment lasts longer and operates efficiently. 3. Versatility: Steel billets can be easily shaped and formed into various components, such as pipes, valves, and fittings, making them highly versatile. This allows for customization and adaptability to specific oil and gas projects, enabling companies to meet the unique requirements of different operations. 4. Safety: The oil and gas industry requires materials that can withstand high-pressure environments and potentially hazardous conditions. Steel billets offer excellent safety properties due to their high strength and resistance to extreme conditions. They are less likely to fail or rupture compared to other materials, reducing the risk of accidents and ensuring the safety of personnel and assets. 5. Cost-effectiveness: While steel billets may have higher upfront costs compared to other materials, their durability and resistance to corrosion reduce the need for frequent replacements or repairs. This leads to long-term cost savings for oil and gas companies. Moreover, steel is a widely available material, making it cost-effective to source and produce steel billets. 6. Environmental Sustainability: Steel is a highly recyclable material, and steel billets can be recycled and reused multiple times without losing their properties. This promotes environmental sustainability by reducing waste and conserving resources in the oil and gas industry. In conclusion, the advantages of using steel billets in the oil and gas industry include their strength, durability, resistance to corrosion, versatility, safety, cost-effectiveness, and environmental sustainability. These properties make steel billets a preferred choice for various applications in the industry, contributing to efficient and reliable operations.

- Q:How are steel billets used in the manufacturing of electrical appliances?

- Steel billets are essential for the manufacturing process of electrical appliances, serving as semi-finished steel products in a rectangular shape. They are used as raw materials for various components of electrical appliances. One primary application of steel billets in electrical appliance manufacturing is in producing motor cores. Motor cores are crucial parts of electric motors found in appliances like refrigerators, washing machines, and air conditioners. The steel billets are processed and shaped into laminated cores, which are then stacked together to form the motor core. These cores provide the necessary structural support and magnetic properties for generating rotational motion. In addition, steel billets are also used in manufacturing electrical wires and cables, which are vital for transmitting electricity within appliances. The billets are processed and drawn into thin wires, which are then insulated and bundled to create the required electrical connections within the appliances. Furthermore, steel billets are utilized in making housings and frames for electrical appliances. These components offer structural support and protection for the internal electrical parts. The billets are processed and molded into various shapes and sizes to create durable and rigid housings capable of withstanding everyday stress and environmental conditions. Overall, steel billets play a crucial role in the manufacturing of electrical appliances, providing the necessary raw materials for motor cores, electrical wires, cables, and housing components. Their strength, durability, and magnetic properties make them an ideal choice for ensuring the quality and performance of electrical appliances.

- Q:How are the surface defects of steel billets repaired?

- The surface defects of steel billets are repaired through a process called grinding or machining. This involves removing the defective areas by using specialized tools and techniques to smoothen out the surface and make it suitable for further processing or use in various industries.

- Q:How are steel billets unloaded at the destination?

- Steel billets are typically offloaded at the destination using different techniques depending on the available infrastructure and equipment. One commonly used approach involves the utilization of cranes or forklifts that are equipped with lifting attachments. These machines have the capability to lift and move the heavy steel billets from the transport vehicle to the designated storage area or processing facility. In certain situations, a specialized unloading facility like a rail yard or port may be utilized. In these cases, cranes or gantry systems are often employed to efficiently transfer the steel billets from rail cars or shipping containers onto trucks or storage areas. This method allows for a more streamlined unloading process, especially when dealing with large quantities of steel billets. Another method that is sometimes employed involves the use of conveyor belts or rollers. This method proves particularly effective when unloading steel billets from a container or truck where they are arranged in a row. The conveyor belt or roller system permits a continuous unloading process, with the billets being moved along the conveyor to the desired location. Irrespective of the method employed, safety precautions are always implemented during the unloading process to ensure the well-being of workers and the prevention of any damage to the steel billets. These precautions may encompass the use of proper lifting techniques, securing the billets during transportation, and the wearing of appropriate personal protective equipment. In summary, the unloading of steel billets at the destination necessitates meticulous planning, efficient machinery, and adherence to safety protocols to ensure a smooth and successful operation.

- Q:What are the main challenges in the marketing of steel billets?

- One of the main challenges in the marketing of steel billets is the highly competitive nature of the industry. There are numerous suppliers and manufacturers of steel billets globally, which creates a saturated market and makes it difficult for companies to differentiate their products and stand out from the competition. Additionally, fluctuations in steel prices and demand can impact the marketing efforts, as companies need to constantly adapt their strategies to changing market conditions. Another challenge is the need for extensive product knowledge and understanding of customer requirements, as steel billets are used in a wide range of industries with specific specifications and standards. Building strong relationships with customers and providing tailored solutions is crucial in overcoming these challenges and successfully marketing steel billets.

- Q:What are the potential applications of steel billets in the medical aftermarket?

- The medical aftermarket offers a wide range of potential applications for steel billets. One important application is the manufacture of surgical instruments, such as scalpels, forceps, scissors, and orthopedic implants. Steel billets are capable of producing high-quality and durable surgical instruments due to the strength and corrosion resistance of steel. Furthermore, steel billets are also useful in the production of medical equipment and devices. For instance, they can be used to create components for X-ray machines, CT scanners, and MRI machines. The excellent conductivity and high strength-to-weight ratio of steel make it a suitable choice for these demanding applications. In addition, steel billets can be utilized in the manufacturing of medical furniture and fixtures. Steel is commonly employed in the construction of hospital beds, examination tables, and cabinets due to its durability and ease of maintenance. Steel billets can provide the necessary raw material for the production of these essential medical items. Moreover, steel billets can also be employed in the fabrication of prosthetics and orthotics. These devices often require materials that are both strong and lightweight to ensure proper functionality and comfort for patients. Steel billets can be processed into various shapes and sizes to create prosthetic limbs, braces, and other orthopedic devices. In summary, the diverse and crucial potential applications of steel billets in the medical aftermarket cannot be underestimated. From surgical instruments to medical equipment, furniture, and prosthetics, steel billets possess the necessary qualities of strength, durability, and corrosion resistance to meet the demanding requirements of the medical industry.

- Q:What is the drop per minute of the billet temperature at 850?

- Cold rolling is not considered. The initial rolling temperature (surface) of the billet is generally 1000-1150 degrees. Generally, the temperature decreases gradually during the rolling process (a small section of high speed wire has a temperature rising process), usually above 750 degrees

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Billet steel from our own mill in good price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15250 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords