All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

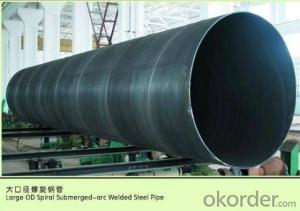

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can welded steel pipes be used for aerospace manufacturing?

Yes, welded steel pipes can be used for aerospace manufacturing. They are often used in various applications within the aerospace industry, such as structural components, fuel systems, and hydraulic systems. However, the specific usage and requirements may vary depending on the specific application and the aerospace manufacturer's specifications.

What are the different types of end connections used for welded steel pipe?

The different types of end connections used for welded steel pipe include butt-welded, socket-welded, and threaded connections.

How are welded steel pipes protected against external damage?

Welded steel pipes are protected against external damage through various methods such as coating, wrapping, and cathodic protection. Coating involves applying a protective layer on the pipe's surface, typically with materials like epoxy or polyethylene, to create a barrier against corrosion and physical damage. Wrapping, on the other hand, involves using materials like tape or thermal sleeves to provide an additional layer of protection. Cathodic protection involves connecting the steel pipe to a sacrificial anode, typically made of zinc or magnesium, which corrodes instead of the pipe, further shielding it from external damage.

Are there any limitations on the transportation and storage of welded steel pipes?

Yes, there are limitations on the transportation and storage of welded steel pipes. Some common limitations include weight restrictions during transportation, which may vary depending on the mode of transport and local regulations. Additionally, the length and diameter of the pipes can also pose limitations on transportation logistics. When it comes to storage, factors such as the environment, handling equipment, and stacking methods need to be considered to ensure the pipes remain undamaged and in good condition.

How is the hardness of welded steel pipe measured?

The hardness of welded steel pipe is typically measured using a standardized test called the Rockwell hardness test. This test involves pressing a diamond or steel ball indenter into the surface of the pipe and measuring the depth of penetration. The hardness value is then determined based on the depth of penetration.

Wholesale Welded Steel Pipe from supplier in Honduras

Thank you for considering us as your leading supplier of Welded Steel Pipe in Honduras. We take pride in offering a comprehensive range of products and services to meet all your needs.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the expertise and resources to fulfill your requirements effectively. Our dedicated team is committed to providing exceptional sales, quotation, and technical support services specifically tailored to the Honduras region.

Whether you need Welded Steel Pipe products for industrial, commercial, or residential purposes, we have you covered. Our years of market development in Honduras have provided us with valuable experience that sets us apart from our competitors. This experience enables us to provide valuable insights and recommendations for your projects, ensuring their success.

By choosing us as your trusted supplier, you can enjoy the convenience of our one-stop procurement services. We are fully equipped to handle your requirements, regardless of the scale or complexity of your project.

Partner with us today and experience the highest quality Welded Steel Pipe products, unmatched customer service, and a seamless procurement process. We are excited to serve you in Honduras and exceed your expectations.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the expertise and resources to fulfill your requirements effectively. Our dedicated team is committed to providing exceptional sales, quotation, and technical support services specifically tailored to the Honduras region.

Whether you need Welded Steel Pipe products for industrial, commercial, or residential purposes, we have you covered. Our years of market development in Honduras have provided us with valuable experience that sets us apart from our competitors. This experience enables us to provide valuable insights and recommendations for your projects, ensuring their success.

By choosing us as your trusted supplier, you can enjoy the convenience of our one-stop procurement services. We are fully equipped to handle your requirements, regardless of the scale or complexity of your project.

Partner with us today and experience the highest quality Welded Steel Pipe products, unmatched customer service, and a seamless procurement process. We are excited to serve you in Honduras and exceed your expectations.