All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

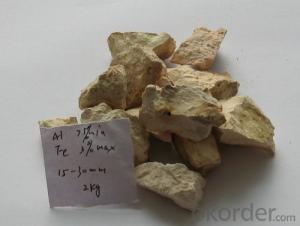

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the differences between acidic and basic refractory materials?

The main differences between acidic and basic refractory materials lie in their chemical compositions and their ability to withstand different types of environments. Acidic refractory materials are made of silica (SiO2) and alumina (Al2O3), and they have high resistance to acidic environments such as those found in metal smelting and processing industries. On the other hand, basic refractory materials are composed of magnesia (MgO) or dolomite (CaMg(CO3)2), and they are highly resistant to basic environments like those encountered in cement and lime kilns. Additionally, acidic refractories tend to have higher melting points and are more resistant to thermal shock, while basic refractories have better resistance to high temperatures and mechanical stress.

How do refractory materials prevent the leakage of molten metals?

Refractory materials prevent the leakage of molten metals by withstanding high temperatures and exhibiting excellent thermal insulation properties. These materials have a high melting point and low thermal conductivity, which helps to contain the molten metal within the desired area. Additionally, refractory materials form a protective barrier between the molten metal and the surrounding environment, preventing the metal from corroding or reacting with the surrounding materials.

How do refractory linings protect against thermal shock?

Refractory linings protect against thermal shock by providing a barrier between high temperatures and the underlying material. These linings are designed to withstand extreme heat and rapid temperature changes, preventing the transfer of thermal energy to the substrate. This insulation property allows the refractory lining to expand and contract without cracking or fracturing, reducing the risk of thermal shock damage to the underlying structure.

Wholesale Refractory Materials from supplier in Honduras

Our team of professionals is highly knowledgeable and skilled in the field of refractory materials. We work closely with our customers to understand their specific needs and provide customized solutions that meet their requirements. Whether you are in the steel, cement, glass, or any other industry requiring refractory materials, we have the expertise to deliver the right products.

In addition to our wide range of refractory materials, we also offer services such as technical support, installation assistance, and maintenance advice. Our goal is to ensure that our customers have a seamless experience from start to finish, and we are always available to answer any queries or provide guidance whenever needed.

At CNBM, we prioritize quality and reliability. We source our refractory materials from trusted suppliers and conduct rigorous quality checks to ensure that every product meets the highest standards. We understand the importance of timely delivery, and we have a robust supply chain system in place to ensure that our customers receive their orders on time.

We take pride in our customer-centric approach and strive to build long-lasting relationships with our clients. Our commitment to excellence and continuous improvement sets us apart in the market, and we are dedicated to providing the best possible solutions for your refractory materials needs in Honduras.

Contact us today to discuss your requirements and let us be your trusted partner for all your refractory materials needs in Honduras.

In addition to our wide range of refractory materials, we also offer services such as technical support, installation assistance, and maintenance advice. Our goal is to ensure that our customers have a seamless experience from start to finish, and we are always available to answer any queries or provide guidance whenever needed.

At CNBM, we prioritize quality and reliability. We source our refractory materials from trusted suppliers and conduct rigorous quality checks to ensure that every product meets the highest standards. We understand the importance of timely delivery, and we have a robust supply chain system in place to ensure that our customers receive their orders on time.

We take pride in our customer-centric approach and strive to build long-lasting relationships with our clients. Our commitment to excellence and continuous improvement sets us apart in the market, and we are dedicated to providing the best possible solutions for your refractory materials needs in Honduras.

Contact us today to discuss your requirements and let us be your trusted partner for all your refractory materials needs in Honduras.

Hot Search

- Monolithic Refractories in Mauritania

- Ceramic Fiber Products in Hungary

- Refractory Bricks in Ecuador

- Raw Materials For Refractory in Peru

- Ceramic Fiber Products in Vanuatu

- Refractory Bricks in Tanzania

- Monolithic Refractories in Cyprus

- Raw Materials For Refractory in Tunisia

- Ceramic Fiber Products in Nigeria

- Monolithic Refractories in Latvia