All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

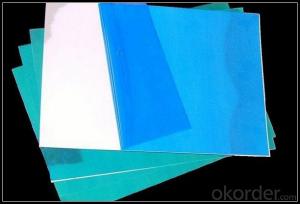

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Aluminum StripsView More

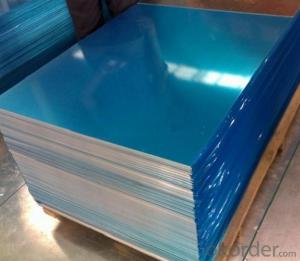

Aluminum SheetsView More

Aluminum CoilsView More

Aluminum FoilsView More

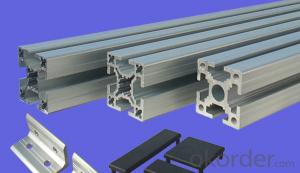

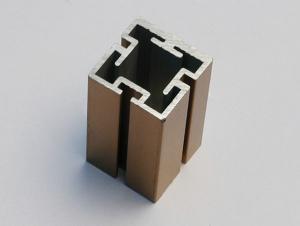

Aluminum ProfilesView More

Q & A

How is aluminum used in the production of aircraft?

Aluminum is widely used in the production of aircraft due to its lightweight, high strength, and corrosion resistance properties. It is used for constructing the airframe, wings, and fuselage as it helps reduce the overall weight of the aircraft, which in turn enhances fuel efficiency and increases payload capacity. Additionally, aluminum alloys are used for various structural components, such as landing gear, engine mounts, and structural supports, ensuring safety and stability during flight.

What are the differences between different aluminum materials?

The differences between different aluminum materials mainly lie in their composition, strength, and properties. Aluminum alloys are created by adding different elements to pure aluminum, resulting in variations in strength, durability, corrosion resistance, and other characteristics. Different alloys are designed for specific applications, such as 6061 aluminum alloy being commonly used in structural applications due to its high strength and weldability, while 5052 aluminum alloy is preferred for marine and automotive parts due to its excellent corrosion resistance. Additionally, tempering processes can further modify the mechanical properties of aluminum, making it softer or harder depending on the desired application.

How to select the width of system window aluminum materials?

When selecting the width of system window aluminum materials, it is important to consider factors such as the size of the window opening, the desired aesthetic, and the structural requirements. The width should be chosen to ensure proper support and stability for the window, while also aligning with the overall design and functionality of the system. Consulting with a professional or supplier can provide valuable guidance in selecting the appropriate width for your specific needs.

Wholesale Aluminum from supplier in Honduras

Whether you are in need of aluminum sheets, profiles, extrusions, or any other aluminum products, we have you covered. Our team of experts is dedicated to providing you with accurate and competitive quotations, ensuring that you receive the best value for your investment.

In addition to our sales and quotation services, we also provide technical support to assist you in choosing the right aluminum products for your specific applications. Our knowledgeable staff can guide you through the selection process, taking into consideration factors such as strength, durability, and corrosion resistance.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, allowing us to source high-quality aluminum products at competitive prices. Our strong relationships with these suppliers enable us to offer you a wide range of options to suit your needs.

Furthermore, our years of experience in the Honduran market have given us valuable insights into local regulations, standards, and industry trends. We can provide you with guidance and expertise to ensure the success of your projects, helping you navigate any challenges that may arise.

At our company, we prioritize customer satisfaction and strive to exceed your expectations. We understand the importance of timely delivery and reliable service, and we are committed to providing you with the best possible experience.

Whether you are a contractor, architect, or distributor, we are here to support your aluminum procurement needs in Honduras. Contact us today to discuss your requirements and let us demonstrate how our expertise and comprehensive services can benefit you.

In addition to our sales and quotation services, we also provide technical support to assist you in choosing the right aluminum products for your specific applications. Our knowledgeable staff can guide you through the selection process, taking into consideration factors such as strength, durability, and corrosion resistance.

As a subsidiary of CNBM, we have access to a vast network of suppliers and manufacturers, allowing us to source high-quality aluminum products at competitive prices. Our strong relationships with these suppliers enable us to offer you a wide range of options to suit your needs.

Furthermore, our years of experience in the Honduran market have given us valuable insights into local regulations, standards, and industry trends. We can provide you with guidance and expertise to ensure the success of your projects, helping you navigate any challenges that may arise.

At our company, we prioritize customer satisfaction and strive to exceed your expectations. We understand the importance of timely delivery and reliable service, and we are committed to providing you with the best possible experience.

Whether you are a contractor, architect, or distributor, we are here to support your aluminum procurement needs in Honduras. Contact us today to discuss your requirements and let us demonstrate how our expertise and comprehensive services can benefit you.