Ziplock bag No. 0 X500

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

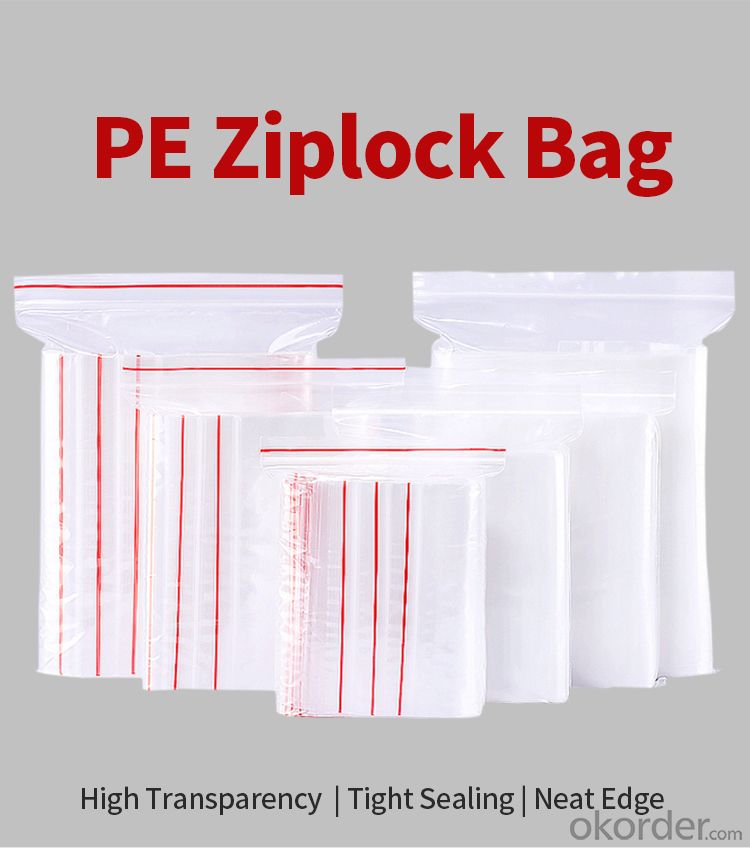

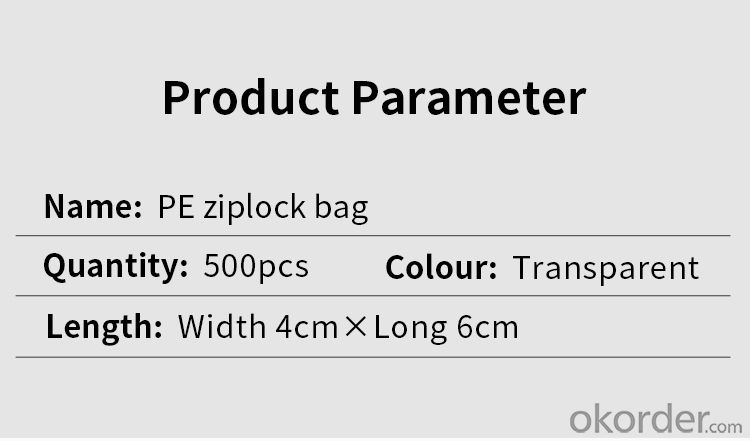

No. 0 ziplock bag, PE material, size: 4*6cm, 500 pcs per pack, transparent bag packaging, the bag is stuck on the surface of the finished product label, our company provides artwork, factory printing, product weight 0.1kg, product length 11.5cm, product width 10cm product Height 3cm

Q&A

Q:Does our product support customization?

A:Our products can support customization, but there are requirements for the quantity, you can contact us for details.

Q:When you call or send a quotation request, what information do you need to provide?

A:Your needs for the product, and what you want to know in detail.

- Q: What does "TM" mean in a food package?

- TM is common in foreign trademarks. It is the abbreviation of "trade mark" in English. "Trade mark" means "commercial mark" in Chinese, so "TM" means "trademark""

- Q: How do I remove the self-adhesive label affixed to the plastic bag?

- Use the lighter directly on the other side of the metal label to burn for a while. The glue on the label will melt quickly. This method works fastest and works best, but it only works for metals.

- Q: Is the packet in the food package a reducing agent or an oxidizing agent?

- The small bag inside the food package is an antioxidant. Belongs to reducing agent.

- Q: What about the use of plastic bags?

- Now all walks of life have the use of plastic packaging bags, only grades, such as the food market is the worst, supermarkets in general, and then to food packaging non-toxic environmentally friendly plastic bags.

- Q: What's the raw material of the cement packing bag?

- Plastic recycling machine is the role of the crushed cleaning waste polypropylene, polyethylene block, sheet, pipe, bottle, film, weaving, silk, pressurized heated in the machine, drawing into strips, the cutter into granular for other plastic processing machinery use.

- Q: What are the soft and hard sides of plastic bags? Material or process technology?

- The quality of plastic packaging is determined by both the material and the process. The material is no better than the good one. But the hardness of plastic is not a decisive factor in determining the quality of plastic, mainly to see what the use of what needs to keep products

- Q: What is the difference between LDPE and PE-LD in a package?

- LDPE is low density polyethylene, and PE-LD should be low density polyethylene. Because according to the PE classification, LDPE (low density polyethylene), MDPE (medium density polyethylene), HDPE (high density polyethylene), VLDPE (low density polyethylene), LLDPE (linear low density polyethylene (mPE), metallocene PE). See, "LD" means "low density".

- Q: How big is the vacuum pack 28*40cm?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: What about the table of nutrition values on food packages?

- serving sizeThe nutrition information displayed in the nutrition information column is based on "every" or "every 100 grams". For foods such as bread, one may be one or two tablets, but for other foods, it may be a little more complicated. A portion that may be only part of the package, or may be part of the normal portion of the meal. Therefore, you need to multiply the actual amount of the food you eat by multiplying the values listed in the nutrition information. 100 grams or 100 milliliters each

- Q: What kind of packaging bag does polysilicon use?

- Polysilicon shall be packed in a clean polyethylene packing bag and sealed;

Send your message to us

Ziplock bag No. 0 X500

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords