YHX LSF Safety Lock

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Guangdong Yuhuaxing Construction Machinery Manufacture Co., Ltd., established in March 1997, is a private enterprise specializing in R&D, designing, manufacturing, selling and leasing of construction machinery. Headquartered in Baiyun District of Guangzhou, it is the council unit of Decoration and Aerial Work Machinery Branch of China Engineering Machinery Industry Association and a member of Guangdong Standardization Association, mainly producing builder hoist, mast climbing work platform, superdeck loading platform, temporary suspended platform, building maintenance unit etc.

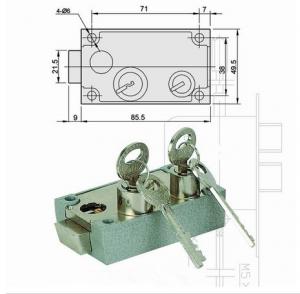

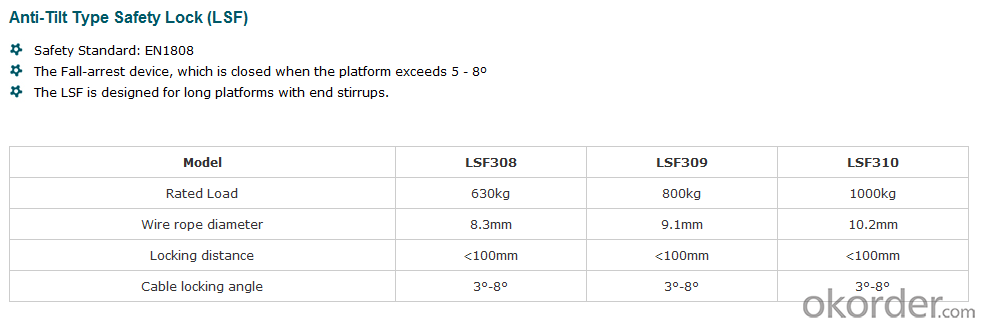

Description of Safety Lock

1. It is a kind of basic component of Suspended Access Platform. Based upon the working principle, it can be divided into LSB30 anti-tilt ones and LSL30 fall arrest ones.

2. When the steel wire is broken or the platform tilts up to 3 - 8 degrees, the safety lock can automatically and securely lock the steel wire and prevent any person from falling. Even the platform falls down, the safety lock is able to lock the wire within 100mm before it is late. Additionally, it can be powered manually when the hoister or motor goes wrong

Key Features and applications of Safety Lock

–well-designed structure, made by superb materials

–easy to manipulate

–ideal for protection against any falls during work in places of high altitude

- manufactured to the latest GB19155-2003 National Safety Standard

Technical Parameters of Safety Lock

Model Pattern Load capacity permitted Wallop permitted Fall distance permitted Tilt angle permitted Required speed

LSB30 Swinging arm lock >800kg 30 kN <100mm 3°~8°

LSL30 centrifugal lock >800kg 30 kN <100mm ≥22mm/min

- Q: This question asks if a building hoist is capable of repeatedly lifting and lowering objects.

- <p>Yes, a building hoist is specifically designed for lifting and lowering objects repeatedly. It is a type of crane used in construction to move materials vertically. The hoist is engineered to handle multiple cycles of lifting and lowering, making it an essential tool for efficient construction work. It is equipped with a motor and a system of pulleys or gears that enable it to perform these tasks safely and effectively, as long as it is properly maintained and operated according to its specifications.</p>

- Q: Is it possible to utilize building hoists in environments with high altitudes?

- <p>Yes, building hoists can be used in high-altitude environments, but their performance may be affected. At high altitudes, reduced air density can lead to decreased efficiency in hoist operations, particularly those powered by combustion engines. It's crucial to select hoists designed for high-altitude use, which may include features such as high-altitude ignition systems and special lubricants. Additionally, regular maintenance and adjustments to the hoist's operation parameters are necessary to ensure safety and optimal performance.</p>

- Q: This question asks about the measures taken to guarantee the safety and reliability of lifting equipment prior to its use in construction.

- <p>To ensure that lifting equipment is safe and reliable before using it in construction work, several key steps must be taken. Firstly, regular inspections and maintenance are crucial to identify any potential issues or wear and tear. Secondly, all equipment should be thoroughly tested and certified by qualified personnel to meet safety standards. Thirdly, proper training for operators is essential to ensure they understand how to use the equipment safely. Additionally, having a comprehensive safety plan in place, including emergency procedures, can help prevent accidents. Lastly, using equipment from reputable manufacturers and ensuring all components are in good working order are also vital for maintaining safety and reliability.</p>

- Q: This question asks for a description of the process of using an emergency stop button specifically in the context of a building hoist.

- <p>To use an emergency stop button on a building hoist, first, ensure you are familiar with the hoist's controls and safety features. Locate the emergency stop button, which is typically a red mushroom-shaped button or switch, prominently placed and easily accessible. In an emergency, press and hold the button firmly. This action will immediately stop all hoist functions, including movement and operation. After pressing the emergency stop, evacuate the area if necessary and notify the appropriate personnel to address the situation. Remember, the emergency stop should only be used in situations where immediate action is required to prevent harm or damage. Regular training and drills can help ensure you are prepared to use the emergency stop button correctly and effectively.</p>

- Q: Is it possible to use a hydraulic cylinder as a substitute for the cylinder in a building hoist?

- <p>While it may be tempting to consider a hydraulic cylinder as a replacement for a building hoist cylinder, it is generally not advisable. Hydraulic cylinders and hoist cylinders serve different purposes and have distinct design specifications. A building hoist cylinder is specifically engineered to handle the vertical lifting and lowering of heavy loads in construction settings, ensuring safety and reliability. Hydraulic cylinders, on the other hand, are used for a variety of applications and may not meet the specific requirements of a hoist, such as load capacity, stroke length, or safety features. Using an inappropriate replacement could lead to mechanical failure, accidents, or even fatalities. It is crucial to use the correct, certified parts for any equipment to maintain safety and functionality.</p>

- Q: This question asks for the method to determine the maximum weight an object can safely be lifted by a lifting device.

- <p>To calculate the weight of an object that can be safely lifted by a lifting device, you must consider several factors. First, determine the lifting capacity of the device, which is the maximum weight it is designed to handle. This information is typically provided by the manufacturer. Next, account for the weight of any additional equipment, such as slings or cables, that will be used in the lift. Subtract this from the lifting capacity to find the maximum weight the object can be. Ensure all safety margins and regulations are observed, as these can affect the safe weight limit. Always err on the side of caution to prevent overloading the lifting device.</p>

- Q: Is it possible to use a building hoist for the purpose of lifting heavy objects?

- <p>Yes, a building hoist can be used for lifting large objects. These hoists are specifically designed to handle heavy loads and are commonly used in construction for lifting materials, equipment, and other heavy items. They are engineered with safety features to ensure secure lifting and are operated by trained personnel. However, it's crucial to ensure the hoist's capacity matches the weight of the object being lifted and that all safety protocols are followed to prevent accidents.</p>

- Q: This question asks whether it is safe to operate a building hoist in adverse weather conditions such as wind and rain.

- <p>The use of a building hoist in windy or rainy weather is generally not recommended due to safety concerns. Wind can cause instability and swaying of the hoist, while rain can lead to slippery conditions and electrical hazards. Most hoist manufacturers and safety guidelines advise against operating hoists in such conditions. However, if absolutely necessary, it should be done with extreme caution, following specific safety protocols, and ensuring all necessary weatherproofing and stability measures are in place. Always consult the manufacturer's guidelines and local regulations before operating a hoist in adverse weather.</p>

- Q: This question asks for a comparison of the pros and cons associated with the use of building hoists in construction projects.

- <p>Building hoists offer several advantages, including increased efficiency in material transportation, reduced labor costs, and improved safety by minimizing the need for manual handling at height. They can also be used for personnel transport, enhancing site accessibility. However, there are disadvantages such as high initial costs, the need for regular maintenance and inspection, and potential downtime due to mechanical issues. Additionally, they require space for installation and can obstruct views or access during operation. Safety concerns also arise if not properly managed, as accidents can occur due to operator error or mechanical failure.</p>

- Q: Is it permissible to use personal manual equipment for lifting objects instead of a construction hoist?

- <p>While it might be tempting to use your own manual equipment for lifting objects, it's generally not recommended for construction purposes. Building hoists are specifically designed for heavy lifting and are equipped with safety features that manual equipment may lack. Using manual equipment can pose significant safety risks, including the potential for accidents and injuries. Always follow safety regulations and use the appropriate equipment for the task at hand to ensure the safety of everyone on site.</p>

Send your message to us

YHX LSF Safety Lock

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords