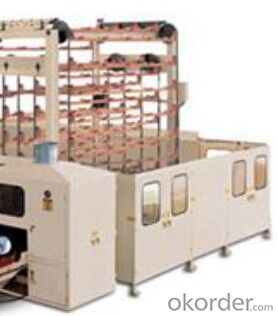

YD-PL350E Non-stop JRT/Industrial Roll Rewinding Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

This line is the newest model which is upgraded on base of our quondam automatic re-winder and foreign technology.

A lot of advanced control technology are used in this line,such as: Program Logic Control System;HMI,;one button Chinese-English switch;synchronous frequency conversion drive;integration of mechanics,electrics and photo.It is equipped with whole trouble information.It can detect and adjust every action of the rewinder automatically to keep the rewinder in optimal situation.For example:There is a web tension system in the line,It can control speed according to the tension of web so it can adapt different type of jumbo roll.So it is the best choice to produce JRT/Industrial roll for paper company. The characteristics of the rewinder are as follows:

1、Unwind is equipped with closed loop frequency conversion control system.

2、When the webs do not align,you can operate on the touch button screen to move the jumbo roll till webs align.

3、When the core unit can not detect core or core will use up, the machine will alarm to tell operator or workers to put some cores on the core bracket.

4、When the machine is running, web break off suddenly for reason of speed change sharply of problem from jumbo roll.

5、Degree of tightness can be adjusted while a log is rewinding.It can produce different degree of tightness in one log.

6、When a log is rewinding,the next core is ready.

7、For the reason of using advanced technology:Program Logic Control System; synch-ronous frequency conversion drive;integration of mechanics,electrics and photo.

8、When the finished log come to tail sealer, trimming, glue spraying and sealing can be finished at the same time.

9、embossing unit and glue applicator、edge embossing unit、printing system is order by customer.

ITEM | 2900 |

Jumbo roll width(mm) | 2850 |

Dimension | Depend on the model and configuration |

Weight | Depend on the model and configuration |

Jumbo roll diameter(mm) | ≤Φ2000(>Φ2000 to order) |

Jumbo roll core diameter | Φ76mm(other size to be specified) |

Finished product dimension | Φ150-280mm |

Finished roll core size(mm) | Φ76 |

Perforation pitch | 4blades:90~160mm(other size to be specified) 2blades:180~320mm(other size to be specified) |

Perforation | 2/4PCS sprial upper perforated |

Rewind | Non-stop |

Parameter setting | HMI |

Finished roll rewinding | Very convenient for with core and coreless interchange |

Control system | PLC,inverter,integration of mechanic,electrics and photo |

Web tension system | Encoder,PLC,inverter |

Transmission system | Gear,timing belt,flat belt |

Compressed air | 0.5~0.8MPa(customer provide) |

Machine speed | Design speed: 350m/min, Produce speed: 300m/min |

Unwind stand | 1-3ply(to be specified),independent drive |

option | |

Embossing unit | Steel to rubber embossing,point to point embosser with lamination,nested embosser with lamination,deco embosser with lamination |

Edge embossing | Steel to steel |

Printing unit | 1~2colors(customer provides pattern) |

Automatic seal unit | Automatic positive web-cut inside and automatic sealing outside machine |

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you have your own website here, through the optimization and promotion, to promote their products out, the customer concern, love content search, when people search through GG to see your home site, you may consult. There are many ways

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- Hello, in recent years, Chinese packaging industry, although the annual growth rate ranked in the traditional industry for the first time, but in line with the international market, to accelerate the development of packaging technology, make its development to the economic, efficient, multi-functional direction. According to the development plan of Chinese national economy and to realize well-off life level, this year a few years for the packaging industry, the food industry to provide equipment for 100 billion yuan to 200 billion yuan, 80 billion yuan to 100 billion yuan to provide equipment for the "vegetable basket", this is a good opportunity for development of enterprises. At the same time, I learned from the relevant ministries, "95" period, will invest 10 billion yuan in the packaging industry to support and transform large and medium-sized packaging enterprises.

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: What machine does the packing carton machine have?

- Packaging equipment including: automatic strapping machine, automatic sealing machine, winding (wrapping) machine, sealing and cutting / shrink machine, vacuum packing machine, automatic strapping machine band and hand tools. Transport equipment mainly include: conveyor belt, roller conveyor, conveyor chain plate, plug-in production line, chain conveyor, conveyor belt etc..

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;Can use blister sealing machine or high frequency plastic welding machine hot pressing;

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- This is really not sure, it can be said that any group, as long as the packaging products are required to use packaging machinery. Most of the products are now in need of packing. So it can be said that any group.

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Different conceptsCompression molding refers to hot forming: mainly for thermoplastic materials (sheet), the use of hot forming machine, Blister molding, I think it should also be considered as a branch of hot stamping, vacuum or high-pressure gas will be used to assist. Hot pressing sheet forming a relatively small depth, relatively simple structure, low precision products, such as packaging materials, plastic pallets, plates in the dishes and so on. There are also forming plate pressing molding (lamination)

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- (especially the telephone communication, stop talking no worries) I think you should understand the specific situation, your target customers first, for example: mechanical models currently in use and the time of purchase, production efficiency, what will be improved after the replacement, can recover the cost of even a few years, these are all what you should do in advance homework.

Send your message to us

YD-PL350E Non-stop JRT/Industrial Roll Rewinding Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords