Xps Foam Board Lowes - Package of Extruded Polystyrene XPS Tile Backer Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulation & waterproofing solutions - Package of Extruded Polystyrene XPS Tile Backer Board

Product name :

CMAX board (as known as construction board, tile backer board, insulation backer board, waterproof backer board, wet room backer board, XPS board.)

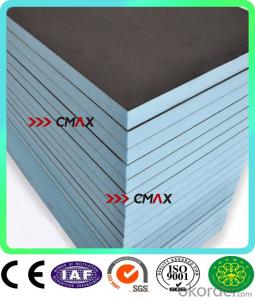

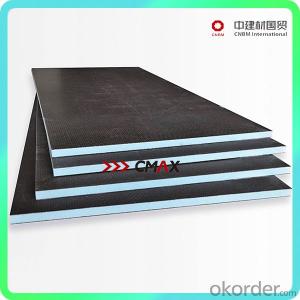

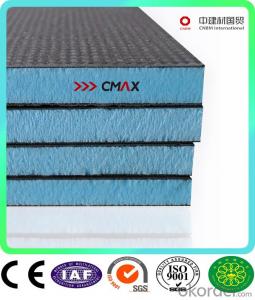

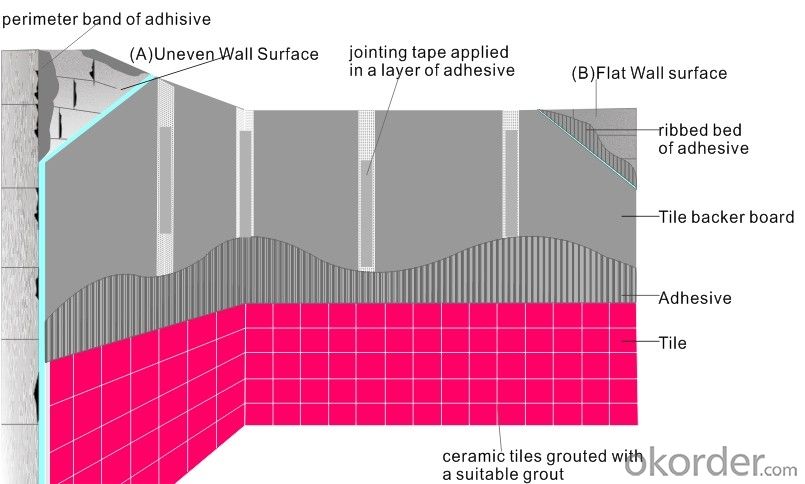

Product structure of Package of Extruded Polystyrene XPS Tile Backer Board:

CMAX boards are made of high-performance waterproof extruded polystyrene (XPS Board), it has a 0.75mm coating on either side comprising a glassfiber mesh embedded in a polymer cement mortar.

Outstanding characteristics of Package of Extruded Polystyrene XPS Tile Backer Board:

Both insulation and waterproof.

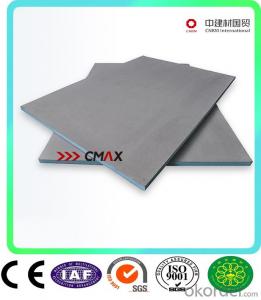

Product appearance of Package of Extruded Polystyrene XPS Tile Backer Board:

The boards have straight edges. The color of the surface is grey and the core material is light blue.

Working temperature range Package of Extruded Polystyrene XPS Tile Backer Board:

50 to +80 °C

Standard dimensions and weight Package of Extruded Polystyrene XPS Tile Backer Board:

Thickness(mm) | Weight(kg/m²) | Length by width(mm*mm) |

6 | 2,7 | 1200 x 600 |

10 | 2,9 | 1250 x 600 |

12 | 3,0 | 2500 x 600 |

20 | 3.1 | 2500 x 600 |

30 | 3,3 | 2500 x 600 |

50 | 4,2 | 2500 x 600 |

The board has the following tolerances:thickness:± 2mm width:± 2mm length:± 3mm.

Reaction to Fire Package of Extruded Polystyrene XPS Tile Backer Board:

The boards are classified as class E according to EN 13501-1. When the boards are covered with tiles, their fire performance should comply with local construction laws and regulations.

Effect on indoor environment Package of Extruded Polystyrene XPS Tile Backer Board:

CMAX board has been assessed as not emitting any particles, gases or radiation that may have a negative effect on the indoor climate or to have any significant effect on health.

Environmental declaration Package of Extruded Polystyrene XPS Tile Backer Board:

The product does not contain any substances on the observation list of dangerous substances published by the national environmental authorities.

Main applications Package of Extruded Polystyrene XPS Tile Backer Board:

Used as a watertight layer on walls and floors in houses, hotels and other wet areas such as bathroom, shower room.

Other applications Package of Extruded Polystyrene XPS Tile Backer Board:

Other places to be insulated and waterproofed.

Applications:

1. as a watertight layer on walls and floors in wet rooms and bathrooms.

2. as an insulation layer in under floor heating to avoid heat loss.

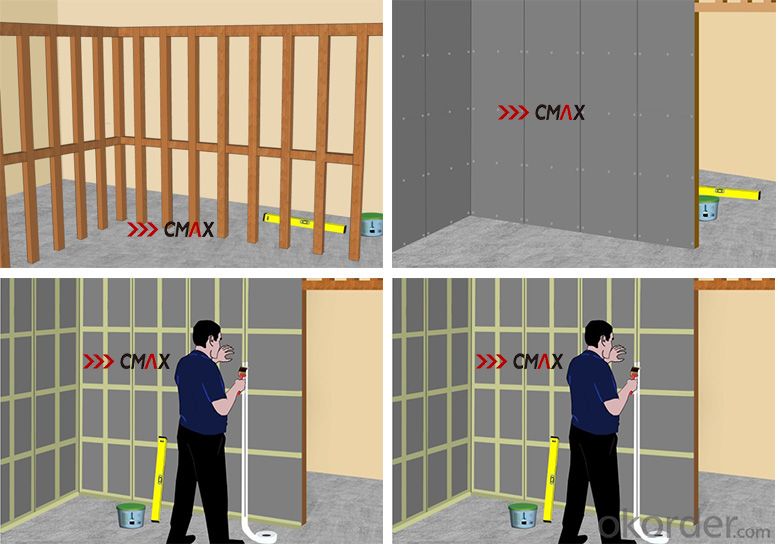

3. as partition walls in wood or steel frames.

4. substitute for gypsum board and fiber cement board; insulation and waterproofing; lighter so that more easily to install.

5. As enclosures for bathtubs, water pipes, etc.

6,Can very easily and fast formed to be small shelves, washbasins, shower benches and soap boxes.

7. Combining with CMAX curved/shapeable boards, kinds of decorative models can be made with your infinite creativity.

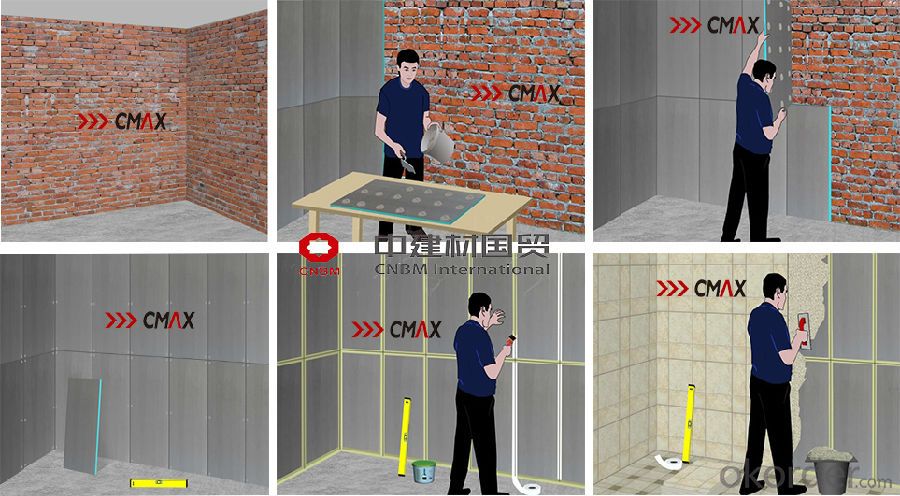

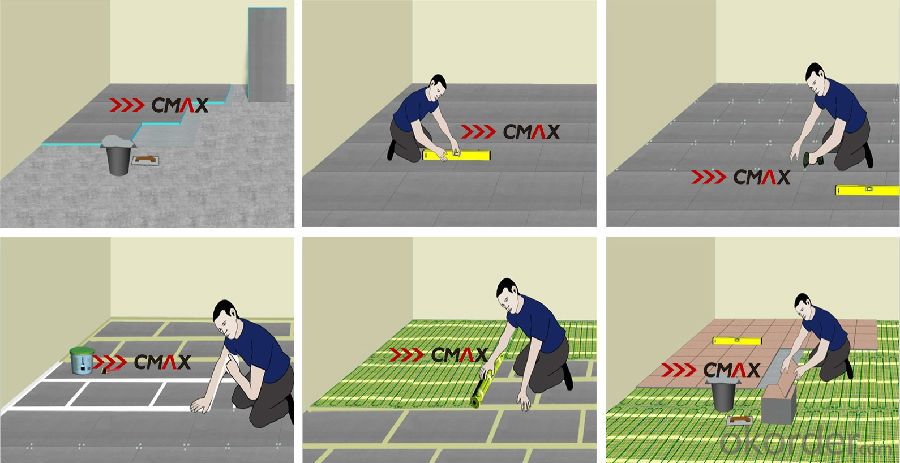

Fixing:

Choose a way to fix CMAX board according to the substrate to be fixed. Normally, using modified tile adhesive for solid concrete wall/floor and strengthened by mechanical fixings when necessary while only using mechanical fixings for wood and steel frames.

Reinforcement:

1. Dry areas: reinforce all joints between boards, floors and walls by 125px or 250px wide self-adhesive tape.

2. Wet areas: reinforce by suitable waterproof tape.

Waterproof strengthen:

1. Strengthening all joints between boards, floors, walls and mechanical fixings placements by suitable waterproof tape.

2. Strengthening joints between walls, outside corners and inside corners by special corners.

3. Sealing pipe holes with special waterproof tape.

4. Strengthening once again by waterproof glue, liquid tanking membrane, tanking membrane paint, etc. when necessary.

Coating of panels Extruded Polystyrene XPS Tile Backer Board:

Should always be covered by ceramic tiles, mosaics or other equivalent non-fireproof materials after installation.

FAQ:

1.

Q: Are you a manufacturer of insulation materials?

A: Yes. ourselves manufacturer of thermal insulation board.

2.

Q: What is the seaport near your plants?

A: The nearest port is Shanghai Port, there are about 100km from the port to our plant in Shanghai.

3.

Q: What is annual production capacity of your main products?

A: 200,000 piecs per month.

4.

Q: Do you have your own brands? And what are they.

A: Yes. we are a fortune 500 company, our brand is "CMAX"

5.

Q: Is sample available for testing?

A: Yes. The sample is free.

We do OEM as well. Welcome to make an enquiry and we will give you quick response in 12 hours!

- Q: 25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- Sandwich board is made of color coated board, stainless steel and other materials as the surface of the composite board, because of its unique dust, anti-static, anti-bacterial effect, is widely used in electronics, pharmaceuticals, food, biological, aerospace, precision Equipment manufacturing and scientific research on the indoor environment demanding clean engineering areas

- Q: What is the difference between extruded polystyrene board and XPS insulation board?

- Is a normal phenomenon, frost in the frost when the frost, and a temperature probe.

- Q: Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- The bar spacing is called 'step distance', 1.2 ~ 1..1.8m, no minimum spacing, maximum 1.8m. Pole spacing 1..1..1.55m, no minimum spacing, maximum 1.55m. See JGJ130 Haifa Fenzhuang Curcuma Gufeng Koufukai -2011 "Construction Construction Fastener Steel Scaffolding Safety Technical Specification" 'Structural Requirements'.

- Q: I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- Think of the safety data directory to compare the trouble to compare JGJ59-2011 check the information bar

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- Can be considered ultra-fine inorganic fiber spraying, this insulation material is sprayed up, not limited by the shape of the building, the speed is still fast

- Q: Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- A type is generally used for pool or wear interior wall, B type for wearing structure (building) building facades Type I seals are suitable for general waterproofing requirements and Type II is suitable for tighter watertight requirements Applicable temperature range: -20 ° C ~ +80 ° C When the wall and pump or booster equipment into the inlet and outlet pipes, it is appropriate to set up a flexible connection at the connection I remember that we are usually the construction of the pipe through the casing into the pool, and then sealed with oil linen casing

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- Flexible waterproof casing for Shanghai Geng high international 薨 uan arm for the seismic fortification requirements of the area, the pipeline through the walls to withstand vibration and pipe telescopic deformation, or a strict waterproof requirements of the building (building) buildings

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- In when Edison in the study of incandescent bulbs, in the white hot filament inserted between a metal sheet

- Q: What is the difference between an extruded board and an XPS extruded board?

- What is the form of this, and you want to be on the scene to be helmet helmet helmet gnome insects rhinoceros kitery to be set. But single, double row scaffolding with a high degree of single-row scaffolding should not exceed 24M, double row scaffolding erection height can not exceed 50 meters, more than 50 meters high double scaffolding should be double pipe, sub-unloading, sub-erection and other measures The "Technical Specification for Safety of Fastener Steel Scaffolding" JGJ130-2011

- Q: How to distinguish between good and bad insulation board insulation board

- Which is good to know how to save the cheek version of the wedge is not very simple can be conclusive. The use of the environment on the impact of different materials, expensive reasons can not be used as a good reference for things, such as the general situation Coke than boiled water expensive, but when the medicine, you say cola good or boiled water is good. 2 kinds of material strength is almost, aluminum good point, toughness is much better PP plastic, but only at room temperature, once the temperature is too high or the bottom, the plastic will be easy to break. Now the plastic process is very developed if the plastic stent is used with some new advanced technology that can improve some of the plastic defects to achieve the metal can not reach the firmness. It is best to buy some, practice to compare it

Send your message to us

Xps Foam Board Lowes - Package of Extruded Polystyrene XPS Tile Backer Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords