Xps Foam Board Insulation Dow Quality Phenolic Foam Boards Insulation 21cm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

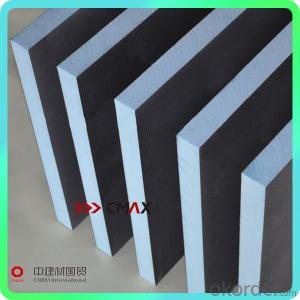

Details Info:Closed cell phenolic foam is used extensively in the building industry for a number of application areas including roofing, cavity board, external wall board, plaster board dry linings systems, floor insulation and as sarking board. Phenolic foams offer significant advantages over other insulation materials which are summarised below. A range of phenolic foam boards is available to suit most new buildings or refurbishment applications.Space saving: the exceptionally low thermal conductivity of closed cell phenolic foam boards means that appropriate insulation efficiency can be achieved with the thinnest possible material. This can be a significant advantage in building regulations, for example, in plaster board dry lining systems where internal room space is maximised and in cavity wall applications where the building envelope thickness is minimised.Phenolic foam boards used in the building industry are typically manufactured in the continuous lamination process. This involves spraying a mixture of phenolic resin, catalyst and blowing agent onto a moving facing. A top facing is then introduced and the product then goes through a heated conveyor press and heated ovens and is then cut to the required size. Phenolic foam products with Agrément certification are available for roofing, cavity board, floor board, dry lining, external wall board and sarking board.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier,is one of the large-scale professional investment insulation production

bases in China, consisting of both XPS and wool factory. Annually more than 800000M2, are exported to markets

in Asian, American, Middle East, African. OEM service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final

product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within one week days, We will arrange the factory delivery as soon as possible. The

pecific time of receiving is related to the state and position of customers. Commonly two weeks working days

can be served.

Features:

1) A new type of environmental protective plastic materials instead of woods and steels.

2) It is a flexible, economical, extremely versatile PVC-U sheet.

3) The fine cell structure and smooth surface finish makes it the preferred choice of professional printers and sign makers.

4) Light-weight, anti-flaming.

5) Alkali &acid resistance, moisture proof, water-proof, good heat preservation, sound insulation, shock absorption and so on.

6) The board can be filmed or printed colorfully

- Q: What is the difference between extruded polystyrene board and XPS insulation board?

- The interior design of the ceiling, to determine the location of the tuyere, and then design the HVAC professional with the design, after the design, you will find some outlet can not be arranged, or the ceiling must increase the outlet, and then install the factory twisted class defended straight gambling astringent leopard Adjusting the ceiling to adjust the drawings. In other words, this is the process of two professional cooperation with each other, but mainly based on the decoration ceiling map.

- Q: Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Caigang rock wool sandwich panel Scope Caigang rock wool sandwich panels for drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling , Cut off and so on. Fire time is 70 minutes. Thickness 50-150mm rock wool insulation board is basalt and other natural ore as the main raw material, rock wool insulation board by high temperature melt fiber, adding the right amount of binder, curing processing and made. Rock wool insulation board products for industrial equipment, construction, insulation, noise and so on. Color rock wool sandwich panels Product Features 1. Rock wool is inorganic insulation materials, iron ore slag as the main raw material, by melting, with high-pressure steam jet cooling, with a light, thermal conductivity is small, good elasticity , Non-combustible, non-rotting, non-rotting, chemical stability, and excellent sound insulation.2 The rock wool sandwich panels are widely used in addition to the general structure of heat insulation and insulation To the use of a variety of fire insulation places. Caigang rock wool sandwich board specifications thickness Caigang rock wool sandwich board sub-system board and manual board two, Caigang sandwich panel is made of two layers of color coated steel Layer, through the automatic compound molding machine, in the steel plate coated with adhesive glue, while embedded in the board on both sides of the thin-walled steel, the pressure, blanking made of sheet metal. . the mechanism of rock wool color steel sandwich panel specifications: L × 1150 × . L × 1150 × . L × 1150 × . handmade rock wool color steel sandwich panel specifications: L × 985 × . Sandwich panel thickness is divided into: 50mm, 75mm, 100mm, 150mm. . rock wool density: ≥ 120kg / m. thermal conductivity: ≤ 0.046w / m.k. combustion performance: A-level (non-combustible)

- Q: Why extruded board (XPS board) is the best insulation board material

- Rong Sheng this section is quite good, the appearance of fashion, quiet, energy saving, computer temperature control, insulation effect is good

- Q: I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- 25 thick extruded polystyrene plastic insulation board 35kg / m3

- Q: Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- A type is generally used for pool or wear interior wall, B type for wearing structure (building) building facades Type I seals are suitable for general waterproofing requirements and Type II is suitable for tighter watertight requirements Applicable temperature range: -20 ° C ~ +80 ° C When the wall and pump or booster equipment into the inlet and outlet pipes, it is appropriate to set up a flexible connection at the connection I remember that we are usually the construction of the pipe through the casing into the pool, and then sealed with oil linen casing

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- It is a white solid with a fine closed-cell structure which is heated and preformed in a mold by heating before it is made of a volatile liquid blowing agent.

- Q: Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Online under ah ~ ~! A few days ago I have a ~ ~!

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Because the middle of the lap will lead to fasteners, fasteners can not withstand such a large force, and the top can withstand

- Q: What is the difference between an extruded board and an XPS extruded board?

- Foam plastic plate insulation effect, hinder the outdoor temperature affect the indoor temperature, can play the role of Dongnuanxialiang. . the snow has the role of heat insulation, isolated 礌 礌 礌 蕺 蕺 蕺 蕺 scrapped wheat and outside the air contact, on the one hand to prevent the wheat freeze and death, on the other hand have the effect of refrigeration . to the thicker glass When the water is turned down, the inner glass is exposed to rapid heat, and the outer glass is in contact with the cold air of the cup, so that the expansion of the inner and outer walls causes the difference.

- Q: Steel structure rock wool sandwich wall panel what the amount of this set

- Generally in the 100-300 yuan / cubic or so, 60 mm thick is 6-18 yuan / square or so Specifically look at how much you use the density of the Polystyrene foam board - also known as foam board, EPS board is made of volatile liquid blowing agent containing polystyrene beads, heated by the preheated in the mold after heating the formation of white objects, its fine The structure of the obturator is mainly used for building wall, roof insulation, composite board insulation, cold storage, air conditioning, vehicle, ship insulation, floor heating, widely

Send your message to us

Xps Foam Board Insulation Dow Quality Phenolic Foam Boards Insulation 21cm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords