Wholesale Washi Tape Packaging for PVC Floor Marking Tape Round Waterproof Heat Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

• World Top 500 Enterprises

• Resistance to cold, heat and aging

• Best quality and competitive price

• SGS&ISO9001, Customs Grade AA

The PVC Floor Marking Tape is of PVC film as the carrier, coating with rubber based adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to electrical products.

The thickness of the tape can be customized.

PVC Floor Marking Tape is ideal for floor marking of sport courts, factories, offices, banks, mails, parking lots, etc. It can also be used for decorating and surface protecting.

FEATURES:

l Excellent in adhesion and flame retardant

l Resistance to cold, heat and aging.

l High Temperature stability

l High mechanical strength and good impact resistance

l Ideal for use in dispensers

l Printable

| Standard size | 50mm*33m, 48mm*33m, 1.25m*33m, etc |

| Thickness (micron) | 130 |

| Color | All Color Available |

| Adhesion to steel (N/cm) | 1.5 |

| Tensile Strength (N/cm) | 18 |

| Elongation at break (%) | 190 |

| Dielectric breakdown (V) | 600 |

| Packing | Carton |

| Delivery | With 10-25days after receiving deposit |

| Payment | T/T & LC |

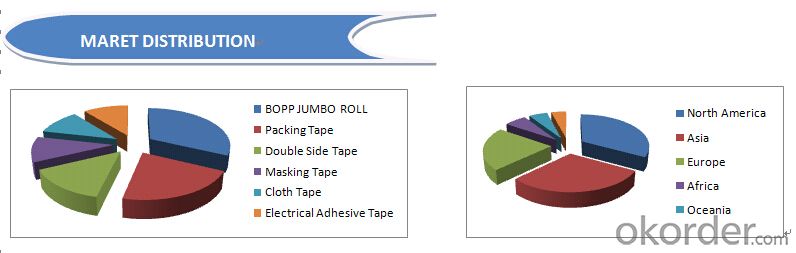

China National Building Materials Group is a state-owned company. As World Top 500 companies, we have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries. We supply adhesive tape for over twenty years.

We supply various adhesive tapes: cloth tape, double sided tape, PVC tape, aluminum foil tape, Opp tape, masking tape and so on. All our products have been SGS and ISO9001 certified and exported with Grade AA approval. The quality and performance all meet the advanced international levels.

We not only own professional manufacturers in China, but also work with many famous brands as agents. We can provide OEM Design & Brand as you required.

1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

2. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Free samples

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Satisfactory sales service

3. Delivery time

7-25 days after receiving the deposit

You are welcome to contact me at any time and visit the factory in China!

- Q: Can packaging tape be used for bundling items together?

- Absolutely, packaging tape is perfect for bundling various items together. It serves as a reliable means to firmly secure and hold multiple objects, particularly when engaged in shipping or relocating. Engineered to possess strength and dependability, packaging tape ensures a steadfast grip that effectively keeps items tightly bundled. Frequently employed for the purpose of bundling boxes, packages, or any other items necessitating cohesion during transportation or storage.

- Q: Is packaging tape safe to use on delicate items?

- Yes, packaging tape can be safe to use on delicate items as long as it is applied with caution and does not directly touch or damage the delicate surface. It is recommended to use a gentle and removable adhesive tape specifically designed for delicate items to ensure their safety during packaging.

- Q: Can packaging tape be used for sealing plastic document holders?

- Yes, packaging tape can be used for sealing plastic document holders. It provides a strong and secure seal to keep the documents inside protected and secure.

- Q: How much weight can packaging tape hold?

- The weight that packaging tape can hold depends on several factors, such as the type and quality of the tape, the surface it is applied to, and the manner in which it is secured. Generally, standard packaging tape can hold up to 20-30 pounds (9-14 kilograms) of weight. However, heavy-duty or reinforced packaging tapes can withstand much higher weights, ranging from 40-70 pounds (18-32 kilograms) or even more. It is important to ensure that the tape is applied properly, with sufficient coverage and pressure, to maximize its holding capacity.

- Q: Has anyone done a tape cut? What about profit?

- I do not know where you belong, but the overall profit is not high, if it is sold to dealers, profits are generally 2.5 to 3 cents a square or so (not deducted from the cost)

- Q: Can packaging tape be used for sealing packages with irregular shapes?

- Yes, packaging tape can be used for sealing packages with irregular shapes. Packaging tape is designed to be flexible and adhesive, making it suitable for securing packages of various shapes and sizes. Its strong adhesive properties enable it to stick to different surfaces, including irregular or uneven surfaces, ensuring that the package remains securely sealed during transit. Additionally, packaging tape is typically durable and tear-resistant, providing an extra layer of protection for the package. Therefore, whether the package has irregular shapes or not, packaging tape is an effective and reliable option for sealing it securely.

- Q: How do I prevent packaging tape from sticking to itself?

- To prevent packaging tape from sticking to itself, you can try folding over a small portion of tape at the end, creating a tab that will make it easier to peel off when needed. Additionally, you can use a dispenser or a cutting tool to cleanly cut the tape, minimizing the chances of it sticking to itself.

- Q: Can packaging tape be used for sealing plastic storage bins?

- Yes, packaging tape can be used for sealing plastic storage bins. Packaging tape is designed to be strong and adhesive, making it suitable for securing and sealing various materials, including plastic bins. It provides a reliable and durable seal that helps to keep the contents of the bins secure and protected. However, it is important to ensure that the tape is applied properly and firmly to ensure a tight seal. Additionally, it is recommended to use a high-quality packaging tape that is suitable for the intended purpose to ensure optimal sealing results.

- Q: Transparent sealing tape 48mm*60y what do you mean?

- 48mm is the width of the tape; 60y is the number of turns

- Q: How does packaging tape perform in freezing temperatures?

- Packaging tape typically performs well in freezing temperatures as it is designed to withstand a wide range of temperatures. However, it is important to ensure that the tape is applied and adhered properly to ensure its effectiveness in cold conditions.

Send your message to us

Wholesale Washi Tape Packaging for PVC Floor Marking Tape Round Waterproof Heat Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords