Whole Aluminum Formwork System in China Market

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Whole Aluminum Formwork Description

Whole Aluminium Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort, subsequently increasing efficiency and reducing general construction time, materials and labour cost. All main components are manufactured from high grade aluminium alloy. This structural grade aluminium has exceptional properties being extremely light in weight but also heavy-duty and durable. When incorporating this into a design which utilizes standard components and allows several possible plan and elevation variables, it provides a lightweight solution for a large area slab formwork system.

2. Main Features of Whole Aluminum Formwork

-Light and easy assemble

-Simple structure.

-Competitive prices

3. Whole Aluminum Formwork Images

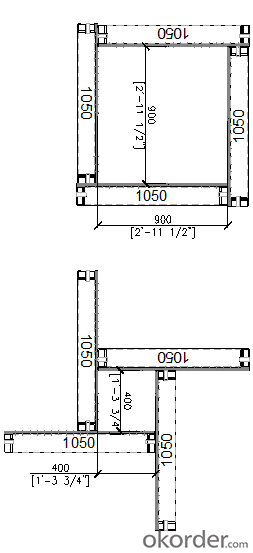

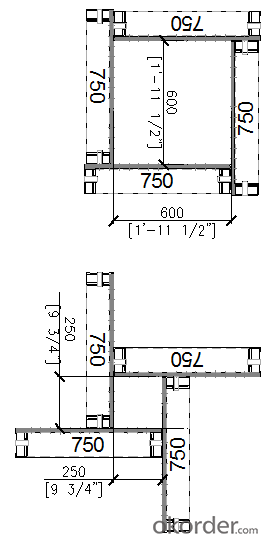

4.Whole Aluminum Formwork Specifications

1) MaximumColumn Size:900 x 900mm

(2’-11.5”x 2’-11.5”)

2) DesignConcrete Pressure: 1,800 psf (90 kN/m2)

3) StandardPanel Width 900mm, 750mm & 600mm

(2’-11.5”,2’-5.5” & 1’-11.5”)

4) StandardPanel Height: 3.0m, 2.4m, 1.2m

5.FAQ of Whole Aluminum Formwork

1) What can we do for you?

We can ensure the quality of the Whole Aluminum Formwork and avoid extra expenses for customers.

We can provide you the professional technical team.

We can provide professional building proposal for your projects.

Please feel free to customize.

2) What promises can be done by us?

If interested in this kind of formwork, please feel free to write us for any QUOTE.

If need any technical and building assistance, we could provide on-site professional staff for instruction.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale services?

Response will be carried out in 24hours after receiving any complain or request.

- Q: What are the mixing arms of the concrete mixer?

- Mixing arm concrete mixer is a component of the mixing arm itself and divided into lateral mixing arm (positive and negative points), stirring arm (also have positive and negative points), stirring arm below is the bearing seat connected, connected with 4 sets of high strength bolts with stirring arm. The top is equipped with wear-resistant mixing blades, connecting with mixing blades, high-strength bolts 2 sets. In addition, some manufacturers have designed mixing side bonded shaft swivel, is installed in the interval between the stirring arm fixed and rotated in two ways.

- Q: What is equipment manufacturing and machinery manufacturing? What's the difference between them?

- Major technical equipment refers to the technical difficulty in equipment manufacturing, complete and strong, is of great significance, has a significant impact on the national economy need to be beneficial to the people's livelihood, complete sets of major technical equipment organizations across sectors, industries and regions to complete.

- Q: What are the principles, performances and uses of the commonly used construction machinery equipment?

- 2.: Principle: loader loader work, powered by a flywheel of the diesel engine to the hydraulic torque converter, the torque converter will drive to the gearbox, and before and after the output flange of the gearbox, the power output of the gearbox after the transmission shaft are respectively transmitted to the front and back drive axle to drive the wheels forward. Performance: 1) Central articulated frame, turning radius is small, flexible and convenient operation in narrow space; 2) using hydraulic mechanical transmission, according to the size of the external resistance and automatic stepless speed change, which can make full use of engine power, and improve the maneuverability, simplifies the loader operation. Is to protect the transmission parts and engine; 3) adopts full hydraulic steering, power shift transmission, hydraulic or flexible manipulation, portable and flexible machine; 4) stable and reliable operation; wide use of low-pressure off-road tires, rear axle swing, with good cross-country performance and through the performance by 5); gas cap oil disc brake system and brake foot up, emergency braking system, the braking performance is safe and reliable; 6) with advanced structure and bright cab. The air conditioning system operates more comfortably. Uses: loaders are mainly used for shovel, loading, unloading, transport of soil and stone a kind of bulk materials, rock and hard soil can also be slightly shovel operations.

- Q: Definition of large mechanical equipment?

- Usually, crane hoisting (make things up and down movement), operation mechanism (the mobile crane), luffing mechanism and slewing mechanism (the horizontal movement of goods), plus metal mechanism, driving device, control device and the necessary auxiliary assembly.

- Q: What are the safety protection equipment, machinery and equipment, construction machinery and accessories for construction enterprises?

- As well as scaffolding, protective fence, all belong to the safety protection facilities, does not belong to the safety protection appliances. Safety protection tools are many, it is characteristic of the operator to carry, I will not list

- Q: How do the welding parts in the welding drawings of the machine parts indicate the technical requirements of the drawings?

- With what groove related, open groove is not the same, marking is not the same, "welding structure" reference to our specialized courses

- Q: Where are the mechanical pressurization air supply facilities set up?

- When the smoke proof staircase and antechamber antechamber, fire elevator or common antechamber parts can be opened outside the window, can use the natural ventilation, resulting in a stairwell with or common antechamber in the use of natural smoke exhaust with pressurized air supply arrangement of diversified combinations, and the two exhaust can not be shared.

- Q: What are the mechanical drawing software?

- The plane is mainly CAD and CAXA, there are some non mainstream mechanical engineer what, mainly engaged in your spare parts of machinery industry, roughness, form and position tolerance requirements, recommendations for CAXA, which symbols are readily available, there are standard parts library, mechanical symbols library etc..

- Q: Mechanical bearings, all types? Roughly

- Spherical roller bearings have two raceways in the inner and outer ring raceways between spherical assembly, a drum shaped roller bearings. The center of curvature of the raceway of the outer race is consistent with the center of the bearing, so it has the same self-aligning function as the self-aligning ball bearing. When the axle and shell are bent, the axial load in two directions can be automatically adjusted. Radial load capacity, suitable for heavy load and impact load. Inner diameter is tapered bore bearings can be installed directly. Or the use of tight sets, the demolition cylinder installed on the cylindrical shaft. The cage uses a steel plate holder, a polyamide forming cage and a copper alloy car holder.

- Q: Where are the hanging baskets for the building?

- It is forbidden to take a stool or put a ladder on a hanging basket to work higher; it is not allowed to work alone in a basket, and no electric machinery or equipment can be placed in the basket;

Send your message to us

Whole Aluminum Formwork System in China Market

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords