Welded Wire Mesh Machine( Factory hot selling Automatic )

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

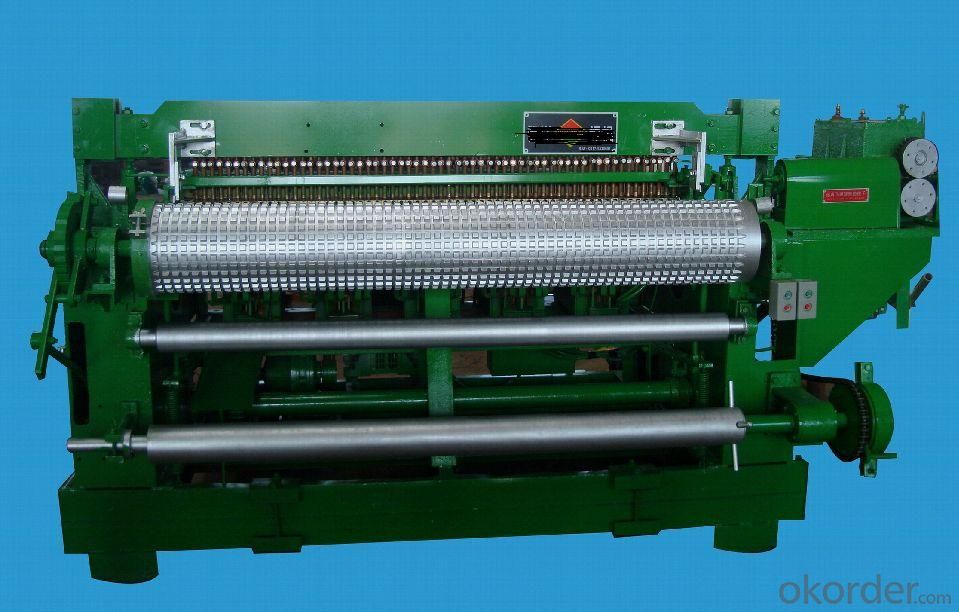

Automatic Welded Wire Mesh Machine( Factory hot selling)

Welding diameter 3.0-6.0(mm)

Welding mesh size 50X50-300X300(mm)

High quality with the best price & customized as your idea!

Automatic Welded Wire Mesh Machine( Factory hot selling)

diameter 3.0-6.0(mm)

Welding mesh size 50X50-300X300(mm)

Welding width 3000(mm)

What fields will the wire mesh welding machine be used in?

1.Water conservancy project, housing construction (floor plate, wall panel), bridge construction, highway construction, airport construction, railway construction, mine protection, which can be widely applied in construction industry.

2.Fence netting (highway, rail road, mountain surrounding and stadium), fence mesh and the production of other protective fences.

3.The production of bird cage, dog cage, various kinds of pet cages and all kinds of breeding cages

4.The production of metal furniture, goods shelf, shopping cart and protective cover

What features does wire mesh welding machine have?

1.The main frame is welded with thick steel plate and section bar, making the main structure more solid and compact.

2.All key parts are made of alloys with heat treatment applied to achieve a very high hardness. Furthermore, the special anti-corrosion treatment is applied for the surface to ensure smooth operation of the parts while preventing corrosion.

3.The welding products are of diversity and the machine can be set according to different production requirements of various kinds, bring flexibility and versatility for customers.

4.The welding adopts new-type high-efficiency welding transformer, which is much more efficient and can make the welding spot more solid compared with traditional transformer.

5.The electric appliances and pneumatic components are all adopt famous brand from foreign countries.

6.Fool-style operation, no matter what kind of operation personnel can easily operate it.

7.About the mesh flatness, this production line adopts the unique welding craft and sophisticated welding control system as well as high-quality copper-cobalt alloy electrodes with special shape, all of which can ensure the flatness of mesh.

Product Details

TECHNICAL DATA

Model | DNW-CNC2000 | DNW-CNC2500 | DNW-CNC3000 | ||

Installed power(kva) | 7*125 | 9*125 | 11*125 | ||

System coltagte(v) | 380V 50Hz | 380V 50Hz | 380V 50Hz | ||

Control voltage(v) | 24V | 24V | 24V | ||

Max.mesh width | 2000 | 2500 | 3000 | ||

Line wire spacing | ≥25mm steplessly adjustable | ||||

Cross wire spacing | ≥50mm steplessly adjustable | ||||

Wire diameter(mm) | 3-6 | 3-6 | 3-6 | ||

Max.welding capacity | 6+6 | 6+6 | 6+6 | ||

Max.wlding speed(time/min) | 30-60 | 30-60 | 30-60 | ||

Max.welding spot nos.(group) | 41 | 51 | 61 | ||

Pressed air(MPa ) | ≥0.8 | ≥0.8 | ≥0.8 | ||

Wire feeding method | In coil/automatic feeding; servo Stepping traction mesh | ||||

Caterconer accutracy | ≤2 | ≤2 | ≤2 | ||

Material | galvanized wire, cold-rolled ribbed wire or low carbon steel wire | ||||

.

- Q: How to do well the maintenance and maintenance of metallurgical machinery equipment

- The main problem in the management of metallurgical machinery and equipment is not systematic. At this stage, the metallurgical industry in China has many new and old equipment mix and match phenomenon, the management is also relatively confusing. Mainly because many enterprises pay more attention to the economic benefits, and pay little attention to the maintenance and maintenance of metallurgical equipment. This leads to the low level of equipment management in the metallurgical industry, and may cause various equipment management problems, so that the service life of various equipment will be reduced, and enterprises will have to pay more economic costs.

- Q: Metallurgical mechanical blade

- Hardness is the basic characteristic of mechanical blade material. The mechanical blade needs to be cut from the workpiece, and its hardness must be greater than the hardness of the material.

- Q: What kind of products are metallurgical equipment in iron and steel works?

- At present, the slab caster is the main equipment in large iron and steel plant, and the most advanced smelting rolling equipment at present.

Send your message to us

Welded Wire Mesh Machine( Factory hot selling Automatic )

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches