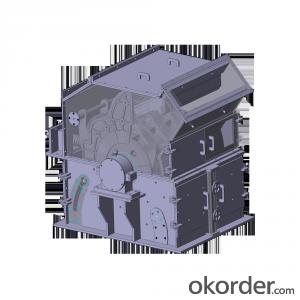

Domestic high-quality stone machinery and equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Classification

Crusher according to the class can be divided into medical crusher and mining crusher.The medical stone machine is mainly used for the crushing stone, generally usingresonance method will stone crushing, avoid all kinds of risks brought by the operation.

According to the principle of common broken broken, heavy mining machinery machineryare jaw crusher, impact crusher, vertical shaft impact crusher, hydraulic cone crusher,hammer crusher, hammer crusher, roller crusher, composite crusher, cone crusher,crusher, double stage gyratory crusher, mobile crusher etc..

The working principle of different types is also completely different, with a ring hammer crusher for example:

Hammer crusher is mainly rely on the impact energy to complete the operation of crushing material. Hammer crusher work, the motor drives the rotor rotate at high speed, the material evenly into the crushing chamber, hammer impact, high speed rotary shear tearingmaterial caused by the material being broken, at the same time, the role of material itselfgravity makes the material from the high-speed rotating hammer head towards the frame body baffle plate, screen, in the lower part of the rotor, with sieve, sieve size materialcrushing smaller than the particle grade discharged through the sieve plate, the materialresistance in sieve sieve size greater than on hammer blow by and grinding.

2 types of Technology

Edit

1, according to the crushing force way to crusher is roughly divided into two categories:

(1) (2) mill crusher

The general processing large material crusher, the product size is coarse, usually larger than 8 mm. The structural characteristics of there is a certain gap between the brokenpieces, not in contact with each other. The crusher can be divided into coarse crusher,crushing machine, fine crushing machine. In general mill processed material is fine, the particle size of the product is fine, up to 0. 074 mm, even the fine. The structure is characterized in crushing members (or medium) contact with each other, the medium is asteel ball, steel bar, gravel or ore etc.. But some machinery is both ore crushing and grinding effects, such as self grinder. Phi 5. 5 x 1. 8 meters from the mill processing of ore size limit of up to 350 ~ 400 mm

2, according to the structural characteristics, mechanical crushing method (action principle)to the division, can be divided into six classes

(1) jaw crusher (tiger mouth). Crushing effect is on the movable jaw plate of periodicpressure to the fixed jaw plate, the clip in which the crushed ore block

(2) the cone crusher. Ore block in two between inside and outside the cone, outer conefixed, the inner conical eccentric swing, clip in which the crushed or broken ore block

(3) roll crusher. Ore block in the two opposite rotating round roller in the crevice, mainly by the crushing action continuous, but also with the grinding effects, toothed roller surfaceand breaking effect

(4) the impact crusher. Ore block by the impact of rapid rotation of the moving parts andcrushed. And it belongs to a class of divided into: hammer crusher; cage crusher crusher;

(5) a mill. Ore by grinding media in the rotating cylinder (steel balls, steel bars, gravel orblock) impact and abrasive and crushed.

A, roller mill: by rotation of the roller will crush the materials.

B, disk mill: the use of a vertical shaft or a horizontal shaft disc rotating as the broken parts.

C, centrifugal attritor. To complete the crushing effect by using the high speed rotating parts and medium production of centrifugal force.

D mill, vibrating mill. The rotary shaft vibration of high frequency, make the medium and material strike against each other and complete crushing effect.

All kinds of crusher has different specifications, different scope. Coarse crushingmultipurpose jaw crusher or gyratory cone crusher; crushing using standard cone crusher;crushing by a short head cone crusher.

The 3 technical indicators

Edit

Mining crusher

Jaw crusher has the characteristics of big crushing ratio, uniform product size, simple structure, reliable work, convenient repair, operation cost. PF-I series of counter functionprocessing length of 100 ~ 500 mm below the material crushing type, its compressive strength is up to 350 MPa, high crushing ratio, crushed material a cube particle etc.; PF-II series crusher is suitable for crushing medium hard materials, such as cement factory,crushing limestone, with a large capacity, a the advantages of small particle size

Mining lithotripsy lithotriptor method

1, using the two generation crushing crushing work surface approximation when theextrusion pressure, the material crushing. Jaw crusher, roller crusher, cone crusher arebroken machinery to crush the ways based on

2, hack is broken by splitting force sharp teeth wedge material of the concentrated force,broken, suitable for brittle materials

3, broken broken materials in working face under concentrated load as the two pivot point(or multi pivot) beam, so the material itself folded broken.

4 performance and usage

Edit

Counterattack crusher although appeared relatively late, but the development of fast. It has been our cement, building materials, coal and chemical industry, mineral processing and other industrial sectors are widely used in all kinds of ores, finely homework. Also used asthe coarse ore crushing equipment. Counterattack crusher is so rapid development is mainly because it has the following important features of the.

Uniform product size crushing phenomenon less. This fragmentation. Broken ore utilizationof kinetic energy, and the kinetic energy of each ore of the ore mass, proportional to.Therefore. In crushing process, lump ore by crushing greatly. But the smaller particles ofore, under certain conditions, it will not be broken. So the crushed product size uniform.

- Q: How to do well the maintenance and maintenance of metallurgical machinery equipment

- The main problem in the management of metallurgical machinery and equipment is not systematic. At this stage, the metallurgical industry in China has many new and old equipment mix and match phenomenon, the management is also relatively confusing. Mainly because many enterprises pay more attention to the economic benefits, and pay little attention to the maintenance and maintenance of metallurgical equipment. This leads to the low level of equipment management in the metallurgical industry, and may cause various equipment management problems, so that the service life of various equipment will be reduced, and enterprises will have to pay more economic costs.

- Q: Metallurgical mechanical blade

- The cutting edge hardness of the mechanical blade used for cutting metal is generally above 60HRC. Wear resistance is the ability of materials to resist wear. Generally speaking, the higher the hardness of mechanical blade material, the better its wear resistance.

- Q: What kind of products are metallurgical equipment in iron and steel works?

- About equipment: continuous casting mold, which is the most important equipment, is the heart of continuous casting, most instructions are executed through the mold, including mold level control, mold level measurement, mould width, dynamic mold expert system, and other steel ladle, ladle nozzle manipulator, bending straightening machine, arc section of horizontal section, roll gap detecting device, hydraulic vibration device, billet guiding device and process control device.

Send your message to us

Domestic high-quality stone machinery and equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches