Birch Plywood WPB Glue Pine LVL Scaffolding Plank for Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 3000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LVL Scaffolding Plank

Laminated Veneer Lumber Scaffolding Board for construction

Features:

1) Dimensions: length: 1980/2980/2500/3900/3980/5980( length within 12 metres)

width: 220/225/230mm

thickness: 38/39/42mm

we may manufacture kinds of sizes according to clients' requirements.

2) Material: Radiate Pine from New Zealand

3) Adhesive: WBP glue ( Environment Friendly )

4) Produce Ability: 60,000CBM/Year

5) Standard:

We are applying an inspection certification from third party agency, now we are instructed under its China agent.

6) SGS Test Report by according AS 1577-1993

7) Usage:

LVL is used primarily as structural framing for residential and commercial construction and is well suited to applications where open web steel joists and light steel beams might be considered. Others uses include scaffold planking and as flange members for some proprietary prefabricated wood I-Joists. LVL can easily be cut to length at the jobsite.

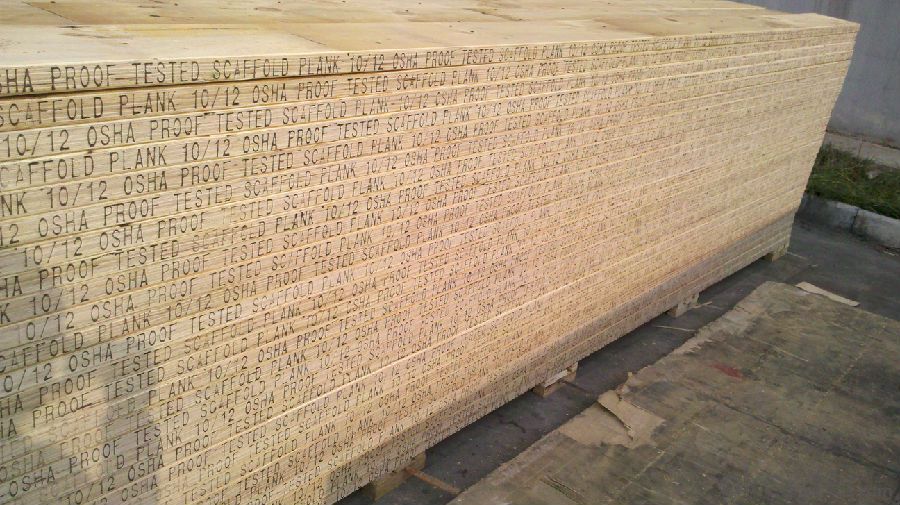

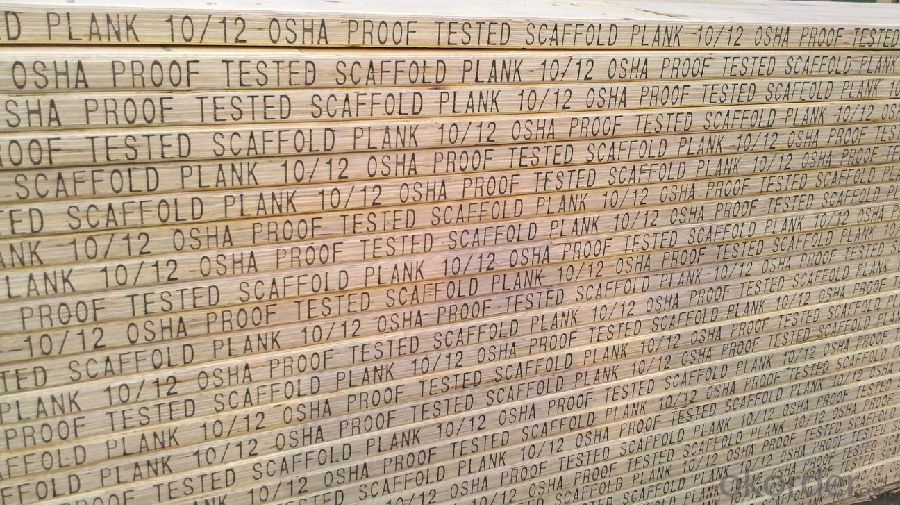

Application: For use as scaffold platforms or decks in accordance with U.S. Department of Labor Regulations (OSHA) or British Standards

Material: Structural laminated veneer lumber (LVL)

Standards: AS/NZS 4357:1995 Structural laminated veneer lumber GB/T 20241- 2006 Standard for laminated veneer lumber ANSI A10.8 – 2001, Safety Requirements for Scaffolding OSHA, Occupational Safety & Health Administration, U.S. Dept. of Labor, Regulations (Standards – 29 CFR) Scaffold Specifications – 1926 Subpart L, Appendix A BS 2482 Specification for Timber Scaffold Boards

Species Used: Plantation forest Radiata Pine

Adhesive & Bond: Phenolic, Type A (WPBP) Bond

Section Size: 38、39、42mm thick x 220、225、230mm wide (Tolerances, -0, +2mm)

Moisture Content: 6% to 18%

Lengths: To customer specification up to 12000mm (Tolerance, -0mm, +10mm)

Approximate Mass: 580kgs/M3

Strength & Stiffness 1) Batch sampling of LVL from production and testing for Verification: Modulus of Elasticity and Modulus of Rupture 2) Boards proof loaded and rigidity measured for verification of strength claims

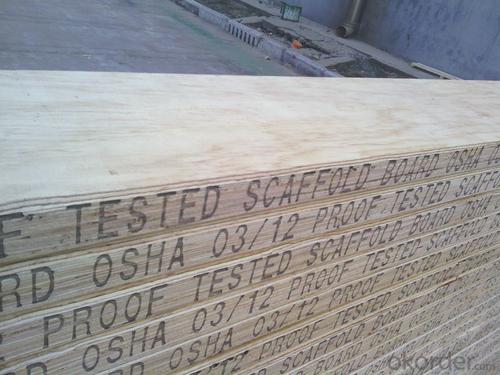

Edge Branding: OSHA, BS2482, PROOF TESTED SCAFFOLD BOARD, MM/YY

Finish: Unsanded faces, sawn edges, arrisses chamfered (to prevent splintering), ends painted (to inhibit moisture egress/ingress)

- Q: National standards for decorative veneer veneer plywood performance requirements

- GB 18580-2001 "interior decoration materials, wood-based panels and their products in the formaldehyde release limit" also provides the product of formaldehyde emission limit.

- Q: What is the composition of the plywood?

- Plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression

- Q: How to use building plywood?

- in the decoration works mainly used in ceilings, wall skirts, floor linings and so on.

- Q: Contemporary plywood market development

- China's rapid economic growth has become a strong traction to promote the market demand for plywood; North China, East China and the middle and lower reaches of the Yangtze River area fast-growing high-yielding forest timber poured into the market

- Q: Further processing of the plywood

- veneer plywood overlaid plywood. Plywood plywood, wood, paper, impregnated paper, plastic, resin film or sheet metal plywood.

- Q: What is the use of plywood for construction?

- Plywood is the direction of the logs along the ring to cut into large sheets of single board, after drying, after coating by the adjacent veneer layer grain direction perpendicular to the principle of the billet, glued from the plate.

- Q: What are the advantages and disadvantages of plywood?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q: What is medium density fiberboard

- The total thickness of the panel and back panel of the joinery board should be greater than 3 mm, and the panels allow proper patching.

- Q: Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Appearance level, size, physical and mechanical properties of the three tests are qualified to determine the product is a qualified product, or judged to be unqualified. P

- Q: What is the plywood made of wood?

- Commonly used plywood type plywood, penta and so on. Plywood can improve timber utilization and is a major way to save wood

Send your message to us

Birch Plywood WPB Glue Pine LVL Scaffolding Plank for Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 3000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords