VIP Boards Reinforced Heat Insulation Steel Plant with Micropore Heat and Thermal Insulation Layer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Reinforced Heat Insulation Steel Plant Using Micropore Heat and Thermal Insulation Layer

Product Description for Reinforced Heat Insulation: Microporous Insulation Boards

Energy is the key to industry and the conservation of energy is a key factor in reducing the environmental impact of industry. It goes without saying that a reduction in the energy consumption of a manufacturing operation will also have a dramatic impact on the profitability of that operation.

In primary Aluminium industry, the energy control is a key , as in one aspect, it can largely increase the thermal efficiency, on the other , it can reduce the cost in an optimistic amount ,by reducing the energy wasting.

Now in China, we has set up a milestone in the whole industry, by using its Microporous Insulation Product named Alu in the aluminium electrolysis cells.

Alu Panels can be easily installed in the wall and the bottom in the electrolysis cells.

The primary aluminium production is carried out in electrolysis cells (pot cells), where alumina dissolved in cryolite is reduced electrolytically to metal aluminium.

State of the art is the insulation of pot cells with: • Microporous Insulation Panel • Vermiculite boards • Moler bricks

The advantage of both Microporous Insulation Panels and vermiculite is that they can be produced in large dimensions. The advantage of Microporous Insulation Panel and of Moler bricks are their superior insulation properties. The presentation explains an advanced design concept with use of calcium silicate

Structure& Advantage for Reinforced Heat Insulation: Microporous Insulation Boards

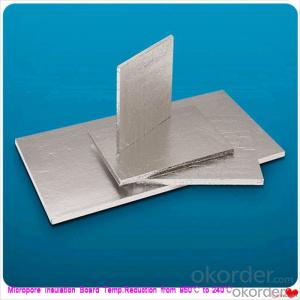

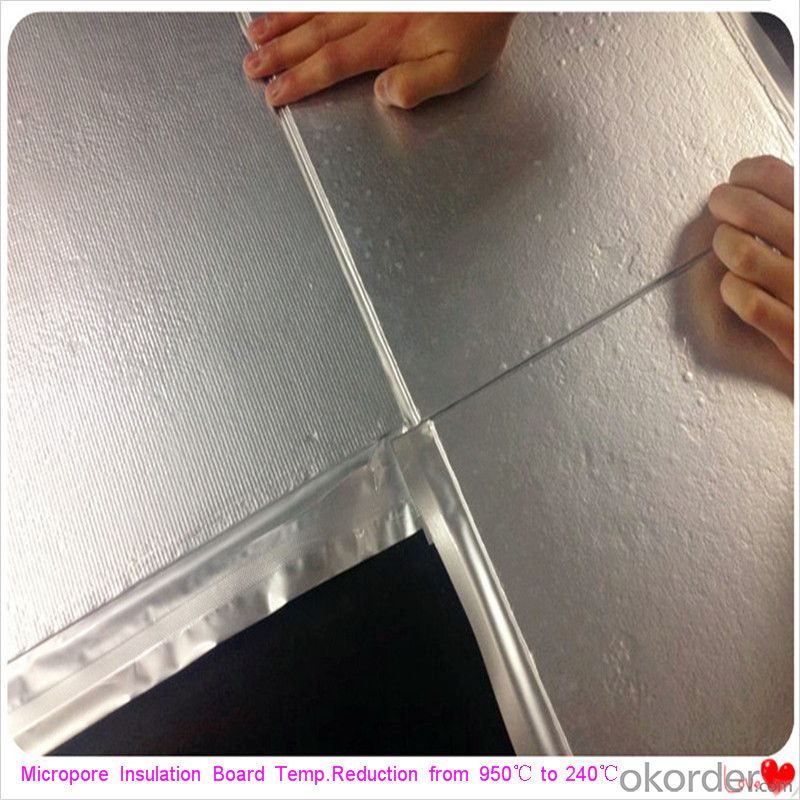

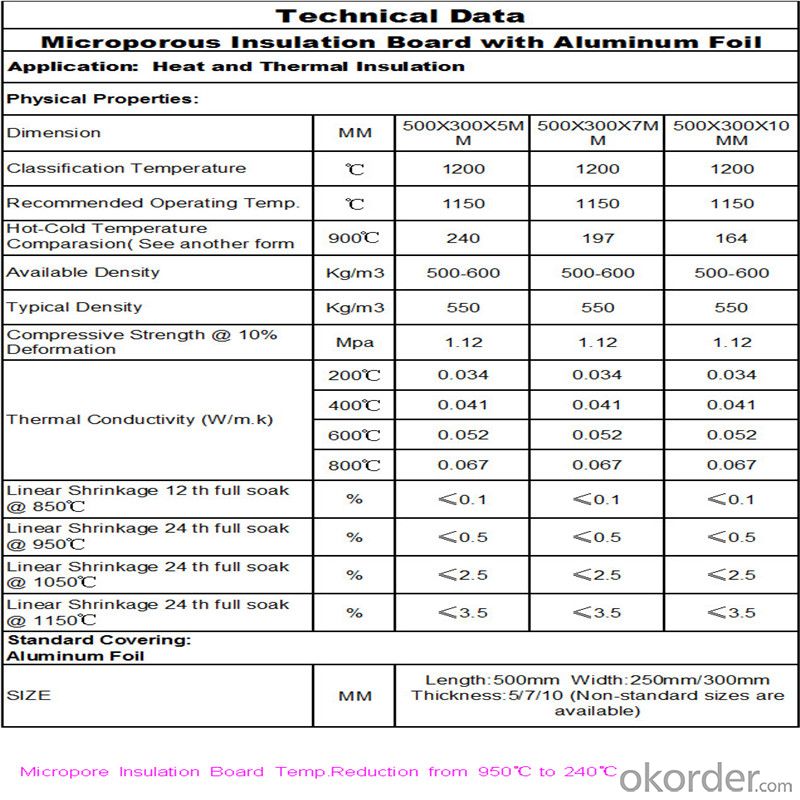

for Micropore/ Microporous Insulation Boards with Alumina Foil Cover

1) Extremely low thermal conductivity

2)High compressive strength

3)High thermal stability

4) Environment protection

5) High thermal stability

6) Environment protection

7) Easy to handle

8) No harmful inhalable fibers

9) Resist most chemical attacks

10) Free of organic binders

Benefits Our Insulation Products Brings You:

1. Reduce the kiln wall thickness from 455mm to 380mm, nearly 16%!

2. Decrease the heat loss of the kiln wall.

3. Save the cost of installation and shorten production lead time by using less material.

4. Shorten the refractory roller length needed for the same capacity kiln.

So after all , you just need invest once in the beginning, and it is the pay-back time of the investment by reducing energy , and heat loss , enlarging space in the following days !

We Are The Major Suppiler for

Using our Micropore/ Microporous Insulation Boards with alumina foil cover

Allied Mineral Products,inc

Refractories Incorporated

SRS Sorg Refractory Systems GmbH, (Germany)

Sunward Refractories Co.,Ltd

Lilama69-1 Joint Stock Company etc.

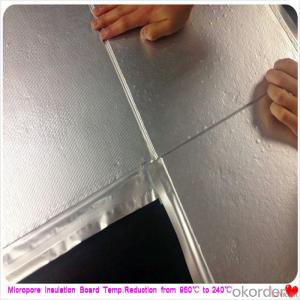

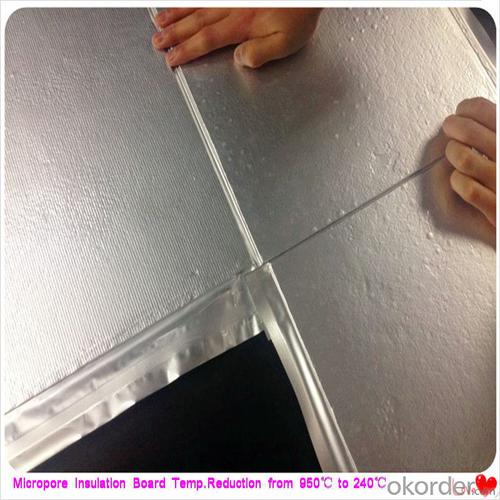

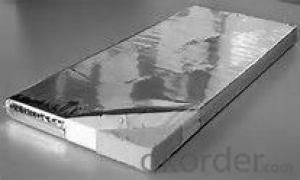

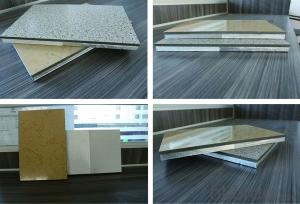

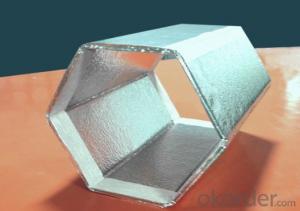

Major Images for Reinforced Heat Insulation: Microporous Insulation Boards

Packaging & Delivery for Reinforced Heat Insulation: Microporous Insulation Boards

Package:each pallet size1100 x 1300 x 1200mm, and packing with plastic foil or case. usually use plastic foil.

Application Images for Reinforced Heat Insulation: Microporous Insulation Boards

Specification Data for Reinforced Heat Insulation: Microporous Insulation Boards

FAQ

Q1:Are you a manufacturer or trader?

A:Manufacturer+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different Reinforced Heat Insulation: Microporous Insulation Boards: Micropore/ Microporous Insulation Boards is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services in 24 hours!!

- Q: I ask, our home is the top floor, the summer is too hot, the walls and roof in addition to the use of insulation board, posted their own kind of tin foil, will not be useful?

- At present, the domestic brand is not clear who is using a good insulation board should be made of silica filler, because the BET for the nano-so the effect is better. Energy saving can reach more than 30 percent

- Q: Is the thermal conductivity of the vacuum insulated plate used to protect the hot plate method?

- Supplementary feifei answer: 1.10kV to the ground safety distance (vertical) is 6 meters, if the 10kV live line below the minimum safe distance (vertical) is 3 meters, "power facilities protection regulations" provides strict construction, housing construction , If it is temporary construction, in the construction should contact the line unit, you can let them send on-site monitoring construction, but must ensure that the safety distance of 3 meters, than the steel pipe, scaffolding and other metal parts in the construction process should prevent the distance from the live line Excessive discharge causes electric shock. 2. If the use of crane construction, according to the "national shield shield uncle 墉 矫 堕 scared scared off the power grid company safety work procedures" provisions in the 5 meters away, to prevent the arm swing accidentally hit the live conductor. If the 10kV line around (both sides) construction, the safety distance and the vertical distance of the same provisions, if the lifting height beyond the live wire should be taken when the wind caused by the swing caused by electric shock 3. "Construction site temporary safety technical specifications" and " Power facilities protection regulations implementation details "provides only the moving objects, such as wires issued trees, houses and other buildings.

- Q: What brand of refrigerator is using a vacuum insulation board? What kind of insulation board is better? More

- What do you mean if you want to get your own steel pipe fastener? Which city is in the city?

- Q: What is the best insulation material? To be waterproof.

- Under normal circumstances, the steel structure of the plant panel can be a single laminated steel plate, double laminated steel plate, composite color plate. Single-layer steel plate used for simple plant or temporary plant roof, this material is affordable, but the insulation effect is poor, easy to leak. Double laminated steel plate effect will be better. Composite color steel plate for the use of insulation materials sandwich practice, insulation and noise effects are very good, but as a roof, the national standard requires sandwich material must be flame retardant or non-combustible materials.

- Q: External wall insulation material which is good, external wall insulation materials

- Indoor insulation material that the best, fire, environmental protection, good insulation effect? ??Glass fiber. Good insulation. Glass fiber cotton with numerous fine gas holes, fibers arranged irregularly arranged, heat conduction breakdown of 0.03w / cm.k, is an excellent insulation material; . with non-flammable. Glass fiber cotton will not burn, no deformation, no embrittlement, can withstand 700 degrees of high temperature, the combustion performance to A1; . environmental non-toxic. As the glass fiber cotton in the manufacturing process does not add any adhesive, so there is no smell, high temperature will not be distributed when the toxic, pungent smell, smell, etc .; . high insulation. As the glass fiber cotton used in the raw material is glass, non-conductive, so it has a very high insulation; . corrosion resistance. Glass fiber is not afraid of strong acid, with a strong corrosion resistance, even if the use of long time will not reduce its functional characteristics; . good recovery Glass fiber contains numerous fixed cavitation, with excellent recovery, not afraid of any shock, tensile strength are more than 1.0kg; . do not want to light field scrambled decanoate containing mutual water. The moisture absorption of glass fibers is usually close to zero, do not worry about there will be water swelling caused by wet cracking of the situation. I hope my answer can help you.

Send your message to us

VIP Boards Reinforced Heat Insulation Steel Plant with Micropore Heat and Thermal Insulation Layer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords