Valve with Positioner AVP300/301 on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

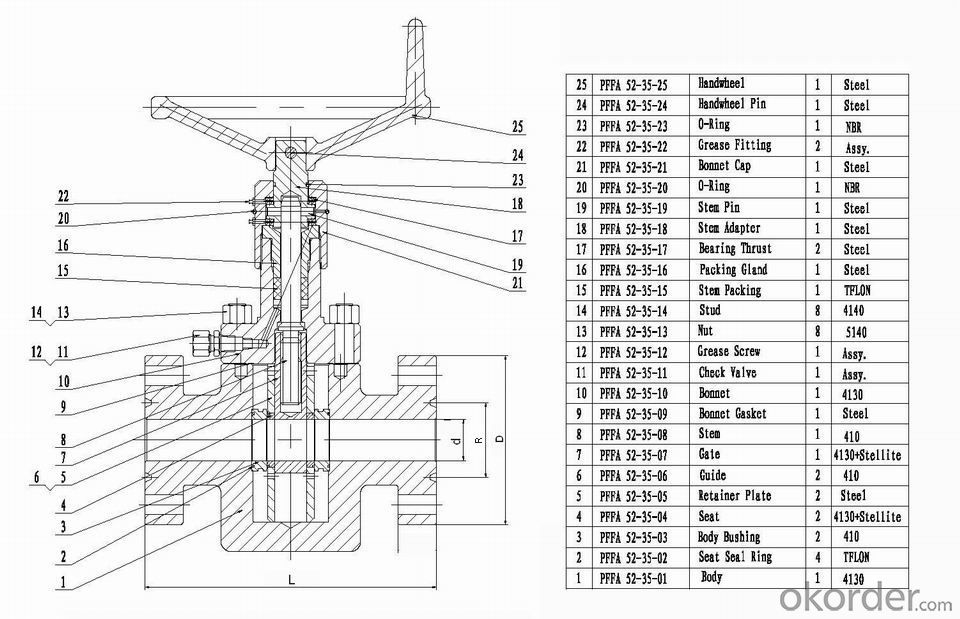

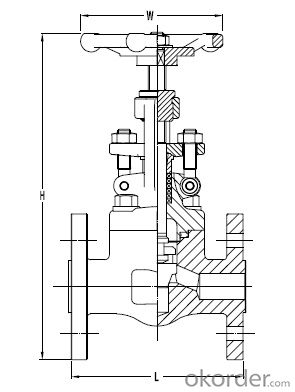

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What does the "XV" valve mean?

- XV if in front of the valve position, such as XV2211-011, then the XV indicates the switch valve, which is a representation of the Control Valve relative to the regulating valve.

- Q: What does "1/2" mean on the valve?

- 1/2 is 4 points (20), 3/4 is 6 points (25), and 1 is 1 inches (32)

- Q: What is the difference between the valve before the pump and the valve after the pump?

- Pump in front of the gate valve + one-way valve, after the pump connected valve, so that in the regulation can be clearly aware of the actual pump lift is large, without the impact of system pressure.Valve is the general name of pumps and valves.A valve that is not used in a pump or with a pump.Pump and valve are often associated with the use of the occasion. In other words, where there is a pump, there is usually a valve, where a valve is often required. They are all used for liquid delivery.

- Q: What does the valve specification "3/4CL150" mean?

- Size: DN20 pressure rating: 150 pounds American Standard

- Q: What does the RF of the valve mean?

- The valve sealing surface in the form and code summary: sealing surface - RF - plane surface process FF ring joint face - RJ - TG groove convex surface - MFM applies to the following: PL flat plate flange hubbed welding neck flange with SO WN IF socket SW screw flange butt welding Th ring loose PJ/SE welding-on collar loose PJ/RJ flange cover BL lining flange cover BL (S) American Standard hubbed SO American Standard wn WN

- Q: I used to do pumps, and now feel the future of the valve better, looking for a valve to do proxy, but my own economic strength is not good, I do not know if there is no possible to do?

- As the saying goes, the valve does not break up. The type of valve is too much, I do not know what you want to proxy valveIf you want to take advantage of the price, please go to Tianjin, or go to the township of Henan valve to see the followingIf you want to take advantage of quality, please go to Henan's Gaoshan Valve Co., Ltd., Yu Ming Valve Co., Ltd., Zhengzhou high and low pressure valve Co., Ltd... I am the valve distributor in Shenyang

- Q: What does the "Z45T-16" valve mean?

- Z - gate valve4 - flange connection5 - Dark pole, stem non lifting (gate valve structure)T - copper alloy, valve sealing face code16 - pressure code, 1.6MPaMaterial code for grey cast iron valves of nominal pressure less than or equal to PN16 shall be omitted in model preparation.May refer to JB/T 308 valve model compilation method

- Q: The valve has a clear opening and closing sign. What does this sentence mean?

- Not only on the valve is enough to mark, here means that at the scene can see the installation of the pipe network on the valve open or shut?!

- Q: What do the D373W and D373H of the valve mean?

- Butterfly valve, worm drive for the folder inclined plate, H alloy steel lining, W for the valve body directly processing sealing surface.

- Q: How are the types of valves classified?

- Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.classificationFunction and use(1) cut off categories: such as gate valve, globe valve, plug valve, ball valve, butterfly valve, needle valve, diaphragm valve and so on. Cut off valve, also known as closed-circuit valve, stop valve, whose role is to connect or cut off the pipeline medium.Check valves, also known as check valves or non-return valves, check valves belong to an automatic valve, its role is to prevent the pipeline medium backflow, to prevent the pump and drive motor reversal, as well as the leakage of container media. Pump water off the bottom valve check valve also belongs to class.The function of the relief valve is to prevent the medium pressure in the pipeline or device from exceeding the required value so as to achieve the purpose of safety protection.Control valve, throttle valve and pressure reducing valve, its role is to regulate the media pressure, flow and other parameters.(2) vacuum type: such as vacuum ball valve, vacuum flapper valve, vacuum air charging valve, pneumatic vacuum valve, etc.. Its function is to change the direction of the air flow in the vacuum system, adjust the air flow rate, cut off or connect the vacuum system of the pipeline, and the component is called the vacuum valve.(3) special uses such as pigging valves, vent valves, drain valves, exhaust valves, filters, etc.. The exhaust valve is an essential auxiliary component in the pipeline system. It is widely used in boilers, air conditioners, petroleum, natural gas, water supply and drainage pipelines. Often installed in the commanding heights or elbows, etc., to exclude excess gas pipeline, pipe road to improve the use of efficiency and reduce energy consumption.

Send your message to us

Valve with Positioner AVP300/301 on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords