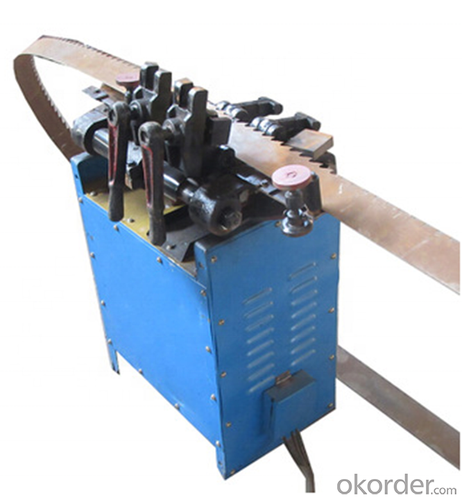

UN6-50 Flash Seal-welding band saw blade butt welding machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of UN6-50 Flash Seal-welding band saw blade butt welding machine

This welder is a special lever pressure type saw blade purpose welding machine,and during welding of saw blades,it needs no weld paste or solder.

It is characterized by an extremely short welding duration and the low energy consumption,and in merely several seconds after being energized,it can surely weld saw blades together.

It is low in cost and the quality of the resulted weld is much superior to that generated by traditional silver soldering or oxygen welding procedures.

2. Parameter of UN6-50 Flash Seal-welding band saw blade butt welding machine

Technical Parameter | UN6-50 | UN6-100 | UN150 |

Welding Saw Blade Width (MM) | 6-50 | 6-125 | 30-150 |

Welding Saw Blade Thickness (MM) | 0.5-1.15 | 0.7-1.25 | 0.7-1.25 |

Voltage | 380V 50 HZ | 380V 50 HZ | 380V 50HZ |

Machine Weight (KG) | 110 | 240 | 308 |

Machine Size(MM) | 650*350*800 | 850*500*1050 | 850*450*1180 |

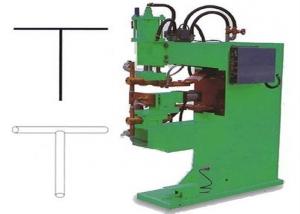

3. Images of UN6-50 Flash Seal-welding band saw blade butt welding machine

4. Packages

Standard export Carton box or plywood box package- Q: Can the coil in the welder be connected to the joint? Does this affect the power of the welding machine?

- Yes, it doesn't work. The thread is not around the magnet

- Q: To the welder 380 V, 36 volt transformer always burn, what's the matter?

- The butt welding machine is intermittently working and won't burn easily. If burned frequently, it means that the no-load current is too large and it is very hot when not working. The countermeasures are: after burn wound, asked the chef to the primary coil (a primary coil) increase the number of turns of 5%, this will not be burned, but the general master are not willing to give you more laps, though you give more money. They will say "the place is not enough." "not open around ah" and so on the grounds, because more laps rarely burned, so messed up their jobs, cut its way. Not just the transformer, the maintenance of the motor is the case. There is a way to let him to ensure the use of time, such as a month burned once, you let him that two years is not burned, is winding double the fee increase, the general master will agree, control the time they have burned, grasp than you.

- Q: Construction site, welding machine, welding machine, tower crane, people, goods, ladders and so on, add up to about 4500W of power, how many thick cables?. It should be about 350 meters

- Is it 380V or 220V? How many KW are there for an electric welder?

- Q: Is the spot welding machine good or DC?

- All the same, the convenient point of communication

- Q: Thank you, find the answer!Senior fellow: for different grades of steel requirements with what electrode problems, I have learned. What I want to know now is whether there is any requirement for the power of the welding machine with different welding electrodes If there is, then this requirement is clear on the specification, or the actual operation of direct existence? If not, is that possible as long as the DC welder is available? For example, the site construction operation radius of 53m, then we have to choose more than 55m and tower type. Troublesome seniors!

- Specific requirements for you to see what the problem of choosing motor electrode, are required, what do you use for electrode current and what specific requirements, the electrode that has will help you choose what what current high current motor

- Q: What kind of reinforcement is needed for 32MM steel bars on Railway overpasses, what kind of welding machine is preferred for welding machines, what brand is selected and what type?. Please help users answer, thank you very much

- 1 、 using UN2-150 welder.2 、 flash butt welding is widely used for longitudinal connection of steel bars and welding of prestressed steel bars and screw end rods. The principle is the use of flash butt welding of reinforcing steel welding ends make contact through the high current low voltage, the steel is heated to a certain temperature to soften the axial pressure on the formation of forging, welding head. Flash butt welding of reinforcing steel, continuous flash welding, preheating flash welding and flash preheating flash welding. The fourth grade steel bar is sometimes treated with electric heating after welding.3, steel (Rebar) refers to reinforced concrete and prestressed reinforced concrete steel, its cross section is round, sometimes with rounded square. Including round steel bar, ribbed steel bar and twisted steel bar. Steel bars for concrete reinforcement is straight or strip steel plate reinforced concrete reinforcement steel, its shape is divided into round steel bar and deformed steel two, straight and coiled state for delivery two.

- Q: How to use PE electric melting machine PE electric welding machine

- Connect the electrofusion pipe to the electric welding machine and plug in both sides of the PE pipe which needs welding. Select the welding time, temperature and other parameters on the electric melting machine, and then operate according to the instructions of the electric melting machine. Different electro melting machines operate slightly differently, not too complicated.

- Q: Saw welding is the use of welding machine, I do not know how good tempering, tempering to what extent, I always break the interface

- Is still another comes back lighter annealing function? It's not a word to make it clear

- Q: The welder is used when the current bottom can not spark is anything to cause

- Low current, no spark, usually there is bad contact, for example: copper and pedestal connection screws loose, resulting in contact surface oxidation resistance, switch contact is not good, etc..

- Q: How many KW generators will be needed for the steel bar welding machine used in the railway engineering construction?

- I remember the welding machine used by the two board of the iron. It was equipped with Cummins 320KW. When the whole factory bought the generator, I asked for it. I'm sure.

Send your message to us

UN6-50 Flash Seal-welding band saw blade butt welding machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches