Electrofusion Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 6 Set per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

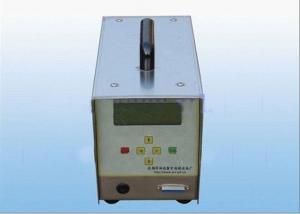

Electrofusion Welding Machine

1. type: electrofusion welding machine

2.welding range : 20~315mm

3. input power: 220V 50HZ

♦ Our eletrofusion welding machine adopt RMS control, main suitable for connection of PE pipes and fittings which are used for natural gas or water supply. It is the perfect equipment for manufacturers or construction units of pipes and fittings.

♦ High brightness LCD display. Chinese/English operation. Friendly interface for human and machine

♦ Wide power supply and voltage input, fully suitable for spot electric network wave

♦ High accurate power , time controlling. Ensure welding quality

♦Huge storage capacity for welding datum, easy way to enter welding parameters

♦ compact design, small volume and light weight

Dimension |

L×W×H(mm) |

330×200×270 |

Input data |

Input voltage |

48V±10%,220V±20% or 380V±20% |

Input power |

40~65Hz | |

Output data |

Output voltage |

0~50V |

Output power |

3.5KW | |

Main

Control

Specification

|

Environment temperature |

-15°C~45°C |

Storage temperature |

-30°C~70°C | |

Control ways |

Constant voltage/currency/power | |

Data record times |

500 | |

Power constant precision |

≤±0.5% | |

Overload capacity |

1.5Ie,1 minute | |

Time control precision |

≤±0.01% | |

Temperature measurement precision |

±0.5°C | |

Duty rates |

60% | |

Data output |

RS232 | |

protection |

See the fault sheet | |

Soft operation |

Windows 2000/XP |

- Q: Do welding electrodes need to be used for the welding machine? Will there be smoke and dust in the welding process?

- Without electrode. Basically no smoke and dustTwo metal charged collision, instantaneous short-circuit discharge

- Q: What's the biggest difference between domestic and imported steel cord welder? Besides price?

- Different quality,Central Wei import, professionalMiddle and South import, one-stop solution. One stop supply chain logistics trade expert!

- Q: Construction site, welding machine, welding machine, tower crane, people, goods, ladders and so on, add up to about 4500W of power, how many thick cables?. It should be about 350 meters

- Friend, you gave this power to the wrong, 4.5KW enough to use ah?

- Q: Is the spot welding machine good or DC?

- AC welding machine is the wire package step-down transformer using welding rod, this machine, old technology, power consumption, copper consumption.The DC welding machine includes thyristor, inverter (MOS tube, IGBT single tube and IGBT module), and the technology is more and more advanced.The inverter is a new technology that has appeared in the last 10 years, saving more than 35%. Because there is no large transformer, a great deal of copper is saved, and the transformer consumption is also reduced a lot. The disadvantage of DC is that the magnetic deviation blows, and the other is all advantages. Arc stability, weld formation is good, and there is welding rod, general acid welding rod is AC and DC can use, alkaline welding rod recommend DC, cellulose electrode, seems to only dc.

- Q: How large can the saw welder be soldered?

- The welding machine can generally weld 10*0.45mm to 150*1.25., which should also consider the power of welding machine.Butt welding machine: butt welding machine, also called current welder. The contact surfaces of two mutually touched metals are instantly fused and fused by an instantaneous high voltage and high current. To achieve the goal of welding 2 pieces of metal together. Flash butt welding mainly uses the workpiece opposite contact resistance to produce heat to heat the workpiece, the metal surface is melted, the temperature gradient is large, and the heat affected zone is relatively small. The weld is formed when the workpiece is facing the solid metal and has plastic denaturation. The weld structure and composition close to the basic metal (or after heat treatment), it is easier to obtain such as strong plastic welded joints.

- Q: When the welding machine works, the contactor sends out a big arc. What is the cause of the main power supply trip?

- When the welder is started, the current is relatively large, and the rated current of the total switch may be smaller than the starting current of the welding machine

- Q: If the welding rod does not release in time, will the electric clamp affect the welding machine?

- The welding rod will affect the welding machine.Welding rod and workpiece adhesion, welding machine is in short circuit state. Short time no influence (not more than 1 second, in fact, the electrode stroke, arc or direct arc welding on the electrode adhesion, the workpiece exactly the same, but the arc time is short). Long time sticky electrode will burn welder.Electrode welding current is too small, basic welding rod arc improper welding stick phenomenon occurs. Need to hold the welding clamp handle promptly with the thumb, rod and gun detachment. To burn the welding machine or cause more accidents.

- Q: Construction steel butt welding or welding good?

- First of all, consider the construction of steel products to be welded quantity and strength requirements.The butt welding belongs to pressure welding and is suitable for mass production in batches.Electric welding is melting welding, its operation is flexible, suitable for field welding, and the two welding methods are different in use, so they can not be replaced by each other.From the performance of the joint, the welded joint is well welded, so the quality of welding is higher than that of the welding.

- Q: Want to do one, but know this knowledge wins, want to know a friend pointing in one or two, thanks in advance! QQ:237411214Have a full set of spare parts can provide the circuit?I want to 2mm thick iron sheet and diameter of about 6mm wire butt, because the product shape is special, outside buy not applicable, so just want to do it yourself.

- There are gear switches, copper strips, electrodes, AC contactors

- Q: Hello, I am doing wire hardware, I would like to know the line welding machine, welding machine, etc., and wire bending, molding, etc., there are no related exhibitions, thank you!!Just to know if there are any related exhibitions

- Although I'm sitting there for a long time, I don't know how to do it like wire hardware.

1. Manufacturer Overview

| Location | Jiangsu,China (Mainland) |

| Year Established | 2001 |

| Annual Output Value | |

| Main Markets | 40.00% Domestic Market 15.00% Mid East 10.00% South Asia 10.00% Southeast Asia 10.00% South America 5.00% Eastern Asia 5.00% Africa 5.00% North America |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese, Spanish, Portuguese, Russian, Korean |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Electrofusion Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 6 Set per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords