TWIN CAGE CONSTRUCTION LIFT ELEVATOR HOIST MODEL SC320/320G

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

BASIC SPECIFICATION:

CMAX SC320/320G (TWIN CAGE)

WORKING HEIGHT: 250M

PAYLOAD: 2X3200KG

RATED INSTALLATION LOAD: 2 X 1000KG

NORD MOTOR, 2X3X18.5KW

WITH VFD SPEED CONTROL (SIEMENS, 2X110KW), 0~63M/MIN

CAGE 2 X (3.2X1.5X2.1m)

MAST SECTION (650x650x1508mm), 93pcs with 4.5mm thickness, 73pcs with 6.3mm thickness

TYPE II MAST TIE-INS(2.9-3.6m), 41pcs

WITH:

▪ Cable Trolley

▪ Safety Device

▪ Hot deep galvanized Cages, Mast Tie-ins (Type II), Mast Sections and Enclosure

The general building hoist manufactured by our company have the features as good quality, long life, wide application range and convenient for maintenance, the gering adopts imported bearing, enameled cable, and oil seal, the electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG, the racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts. The steel structure uses quality steel from famous domestic manufacturers, the surface of the structure can apply paint-spray, Parkerizing baking finish or hot galvanizing processing according to users requirements, the cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminum board.

ADVANTAGES:

1. Our own systems of production engineering.

2. Production design from the concept to the engineering details.

3. Technical experts with great experience in the sector.

4. Continuous development of new solutions and products adapted to the requirements of our clients.

5. Methodology and project procedure administration in compliance with current guidelines.

6. Extensive worldwide commercial network

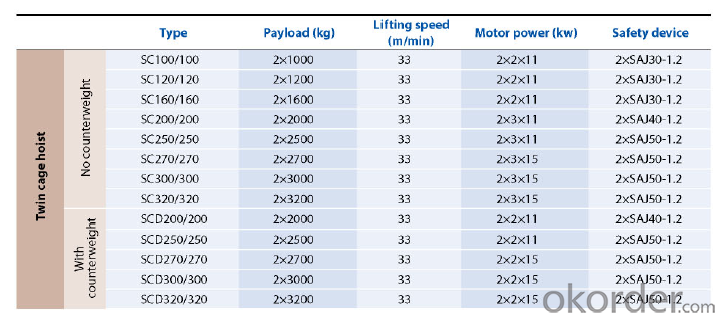

TABLE OF SPECIFICATION (FOR REFERENCE):

FAQ

1. WHY US?

China National Building Materials (Group) Corporation (CNBM), established in 1984,now is one of the largest state-owned group corporation in China, dealing with building materials & industrial equipment. Up to year 2010, CNBM Group's total asset is 20 billion USD and total staff is more than 100,000.CNBM International Corporation, specializes in designing & manufacturing of various

kinds of construction machinery, including tower crane, building hoist, etc. All the equipment produced by CNBM are compliant with the National level quality standard, and wins great reputation for their endurable performance in worldwide markets.

2. WHAT IS THE PRODUCTION AND SHIPMENT SCHEDULE?

Our hoists are normally ready to be shipped within 30 days. The goods are packed nude and in wooden boxes and are placed inside containers.

3. DO WE OFFER AFTER SALES SERVICE?

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

- Q: What fundamental specifications or conditions must be met to operate a building hoist with a hydraulic pump?

- <p>To use a hydraulic pump to power a building hoist, several basic requirements must be met: a reliable power source, a suitable hydraulic pump with the correct pressure and flow rate, a robust and leak-free hydraulic system, safety mechanisms such as pressure relief valves and emergency stop features, proper installation and maintenance procedures, and adherence to safety standards and regulations. Additionally, the pump should be compatible with the hoist's design and capable of providing the necessary force and speed for lifting operations. Regular inspections and maintenance are crucial to ensure the hoist operates safely and efficiently.</p>

- Q: What precautions should be taken when using lifting equipment to ensure safety?

- <p>Safety measures for lifting equipment include regular inspections and maintenance to ensure equipment is in good working order. Operators must be trained and certified for the specific equipment they are using. Safe lifting practices should be followed, such as never exceeding load limits, using the correct lifting points, and securing loads properly. Personal protective equipment (PPE) should be worn, and clear communication among the lifting team is essential. Additionally, a safe working environment should be maintained, free from obstructions and hazards, and emergency procedures should be in place and known by all involved.</p>

- Q: This question asks about the measures taken to guarantee the safety and reliability of lifting equipment prior to its use in construction.

- <p>To ensure that lifting equipment is safe and reliable before using it in construction work, several key steps must be taken. Firstly, regular inspections and maintenance are crucial to identify any potential issues or wear and tear. Secondly, all equipment should be thoroughly tested and certified by qualified personnel to meet safety standards. Thirdly, proper training for operators is essential to ensure they understand how to use the equipment safely. Additionally, having a comprehensive safety plan in place, including emergency procedures, can help prevent accidents. Lastly, using equipment from reputable manufacturers and ensuring all components are in good working order are also vital for maintaining safety and reliability.</p>

- Q: Is it possible to use a building hoist to lift objects that are too large to pass through a standard doorway?

- <p>Yes, a building hoist can be used for lifting objects that are too large to fit through a doorway. Building hoists are designed to handle heavy and oversized items, lifting them vertically through small openings or directly from the ground to higher floors. They are particularly useful in construction projects where large materials or equipment need to be moved to upper levels of a building. However, it's important to ensure the hoist is properly installed and operated by trained personnel to maintain safety and avoid damage to the building or the items being lifted.</p>

- Q: What are the specific safety mechanisms and controls that are typically incorporated into the design of a building hoist to ensure its safe operation?

- <p>Building hoists, also known as construction hoists, are equipped with several safety devices and controls to ensure safe operation. These include limit switches to prevent overtravel, safety locks that engage if the hoist sways excessively, emergency stop buttons for immediate cessation of movement, overload protection to prevent the hoist from lifting more than its capacity, and interlock systems that ensure the hoist cannot operate if a safety gate is open. Additionally, there are guardrails, toe boards, and anti-fall devices to protect workers from falling. Regular inspections and maintenance are also crucial for the safe operation of building hoists.</p>

- Q: This question asks for methods to reduce the time a lifting device, such as a building hoist, is not operational and the expenses associated with its upkeep.

- <p>Minimizing downtime and maintenance costs for lifting equipment, including building hoists, involves a combination of proactive measures and regular maintenance. Implement a preventive maintenance schedule to address potential issues before they cause significant downtime. Use high-quality components to reduce the frequency of repairs. Train operators to handle equipment correctly and perform basic troubleshooting. Regularly inspect and lubricate moving parts to prevent wear and tear. Implement a condition monitoring system to detect early signs of malfunction. Finally, keep spare parts readily available to expedite repairs and minimize downtime.</p>

- Q: How does the elevator operate

- The application of the construction elevator has gained popularity over the years, and has attracted many employees. The construction elevator is a highly skilled industry, so it is required that the professionals must master certain expertise. Here is a knowledge of how to operate a lift machine, hoping to help you.

- Q: This question asks for an explanation of the functioning of hydraulic cylinders in lifting equipment.

- <p>Hydraulic cylinders in lifting equipment operate by converting hydraulic pressure into linear mechanical motion. They consist of a cylinder barrel, a piston, and a piston rod. When pressurized fluid is introduced into the cylinder, it pushes the piston, which in turn moves the piston rod. This movement is what lifts or moves the load. The force exerted by the piston is proportional to the pressure of the fluid and the area of the piston. The cylinder's design allows for controlled and precise lifting, making it ideal for heavy-duty applications where power and control are required.</p>

- Q: This question asks for guidance on selecting appropriate lifting equipment based on specific requirements and work conditions.

- <p>To choose the right type of lifting equipment for your specific needs and work environment, consider the following: 1. Load capacity: Ensure the equipment can handle the weight of the items you need to lift. 2. Workspace: Evaluate the size and layout of your work area to determine the appropriate size and type of equipment. 3. Safety features: Look for equipment with safety features that meet your industry's standards. 4. Mobility: Consider whether you need a mobile or stationary unit. 5. Compatibility: Ensure the equipment is compatible with other tools or machinery you use. 6. Budget: Determine your budget and find equipment that offers the best value for your investment. 7. Consult with experts: Speak with equipment manufacturers or distributors to get their recommendations based on your specific needs. Always prioritize safety and efficiency when selecting lifting equipment.</p>

- Q: Is it possible to utilize building hoists for construction purposes?

- <p>Yes, building hoists are commonly used in construction work. They are essential for lifting and lowering materials, tools, and sometimes personnel between different floors of a building under construction. These hoists enhance efficiency by reducing manual labor and improving safety by minimizing the risk of accidents associated with manual handling of heavy loads. They are designed to be robust and reliable, making them a vital piece of equipment in the construction industry.</p>

Send your message to us

TWIN CAGE CONSTRUCTION LIFT ELEVATOR HOIST MODEL SC320/320G

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords