CONSTRUCTION LIFT ELEVATOR HOIST MODEL SC200/200

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

BASIC SPECIFICATION:

CMAX SC200/200G BUILDING HOIST

Height 150M

Lifting Speed 0 -63m/min

Payload Capacity 2x2000kg

Cage Size 2 X (3.2X1.5X2.1m) Hot Galvanized

Motor Power 2x3x11KW Nord or China Motor

Inverter Power 2x75kw (Siemens)

Safety Device SAJ50-1.4

Mast Section Size 650x650x1508mm (Hot Galvanized)

Mast Section Thickness 4.5mm

Tie-in-type II Type (2.9 - 3.6m, Hot Galvanized)

Power Supply 440V, 3 Phase, 60hz

The general building hoist manufactured by our company have the features as good quality, long life, wide application range and convenient for maintenance, the gering adopts imported bearing, enameled cable, and oil seal, the electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG, the racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts. The steel structure uses quality steel from famous domestic manufacturers, the surface of the structure can apply paint-spray, Parkerizing baking finish or hot galvanizing processing according to users requirements, the cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminum board.

ADVANTAGES:

1. Our own systems of production engineering.

2. Production design from the concept to the engineering details.

3. Technical experts with great experience in the sector.

4. Continuous development of new solutions and products adapted to the requirements of our clients.

5. Methodology and project procedure administration in compliance with current guidelines.

6. Extensive worldwide commercial network

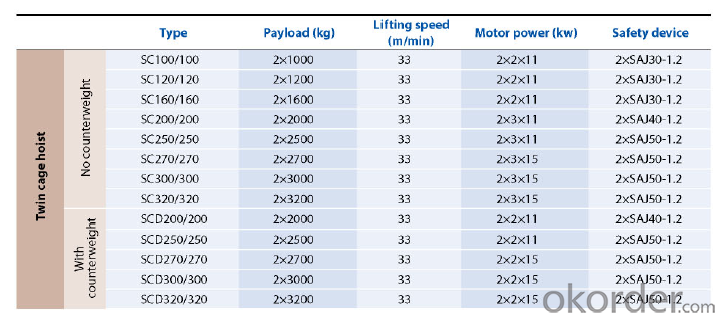

TABLE OF SPECIFICATION (FOR REFERENCE):

FAQ

1. WHY US?

China National Building Materials (Group) Corporation (CNBM), established in 1984,now is one of the largest state-owned group corporation in China, dealing with building materials & industrial equipment. Up to year 2010, CNBM Group's total asset is 20 billion USD and total staff is more than 100,000.CNBM International Corporation, specializes in designing & manufacturing of various

kinds of construction machinery, including tower crane, building hoist, etc. All the equipment produced by CNBM are compliant with the National level quality standard, and wins great reputation for their endurable performance in worldwide markets.

2. WHAT IS THE PRODUCTION AND SHIPMENT SCHEDULE?

Our hoists are normally ready to be shipped within 30 days. The goods are packed nude and in wooden boxes and are placed inside containers.

3. DO WE OFFER AFTER SALES SERVICE?

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

- Q: This question asks if a building hoist is capable of lifting heavy objects.

- <p>Yes, a building hoist is specifically designed to lift large objects. It is a type of crane used in construction to move heavy materials and equipment to different levels of a building under construction. Building hoists can handle a significant weight, but the exact capacity depends on the specific model and its design specifications. They are essential for efficient construction processes, ensuring the safe and effective transportation of materials within the construction site.</p>

- Q: What is the function or use of constructing a building hoist?

- <p>The purpose of building hoists is to facilitate the vertical transportation of materials, equipment, and sometimes personnel during the construction process. They are essential for moving heavy items to various floors or levels of a building under construction. Hoists enhance efficiency, reduce manual labor, and improve safety by minimizing the risk of accidents associated with manual handling of heavy loads. They are particularly crucial in high-rise construction where access is limited and the volume of materials to be moved is substantial.</p>

- Q: Is it permissible to use a building hoist for lifting people?

- <p>Building hoists are not designed for lifting people and doing so can be extremely dangerous. They are specifically engineered for the transportation of materials and equipment in construction settings. Using a building hoist to lift people violates safety regulations and can result in severe accidents. Always adhere to the manufacturer's guidelines and local safety laws, which prohibit the use of building hoists for carrying personnel.</p>

- Q: This question asks about the steps or measures to ensure the safe installation of a building hoist, which is a device used in construction for lifting materials and personnel.

- <p>To install a building hoist safely, follow these steps: 1. Ensure the site is clear and secure, with proper access and no obstructions. 2. Check that the hoist is suitable for the load and building structure. 3. Assemble the hoist according to the manufacturer's instructions. 4. Install the hoist on a stable and level base, ensuring it is securely anchored to the building. 5. Conduct a thorough inspection of all components for any defects or damage. 6. Test the hoist with a trial run to ensure all functions work correctly. 7. Train operators on the safe use and operation of the hoist. 8. Obtain any necessary permits and inspections from local authorities. 9. Regularly inspect and maintain the hoist to ensure ongoing safety.</p>

- Q: Is it possible to use a building hoist to lift multiple items simultaneously?

- <p>Yes, a building hoist can be used for lifting multiple objects at once, provided that the combined weight of the objects does not exceed the hoist's load capacity. It's important to ensure that the hoist is designed for such use and that safety precautions are strictly followed to prevent accidents. The objects should be secured properly to avoid any shifting during the lift, and the operation should be conducted by trained personnel to maintain safety standards.</p>

- Q: The user is asking if it's possible to substitute a hydraulic lifting device for a building hoist in construction.

- <p>Yes, a hydraulic lifting device can be used as an alternative to a building hoist in certain scenarios. Hydraulic devices offer precise control and smooth operation, which can be advantageous for lifting heavy construction materials. However, it's important to consider the specific requirements of your project, such as the weight and size of the materials to be lifted, the height of the lift, and the frequency of use. Hydraulic systems are generally more expensive and require more maintenance than building hoists, but they can provide greater lifting capacity and versatility. Always ensure that any lifting device used complies with safety standards and regulations.</p>

- Q: Is it possible to use a building hoist for lifting light objects without any additional tools?

- <p>Yes, a building hoist can be used for lifting light objects without using any tools. Building hoists are designed to lift a variety of materials, including lighter items, within their weight capacity. However, it's crucial to ensure that the hoist is rated for the weight of the object and that safety protocols are followed to prevent accidents. Always consult the hoist's manual for specific guidelines on weight limits and safe operation procedures.</p>

- Q: This question asks whether a double-rope lifting system can be safely and effectively used in both indoor and outdoor environments, specifically during windy conditions.

- <p>A double-rope lifting system can be used both indoors and outdoors, but its use in windy conditions requires careful consideration. Indoors, it is generally safe and effective. Outdoors, windy conditions can pose challenges. High winds may cause the load to sway, potentially leading to accidents. Therefore, it's crucial to adhere to safety guidelines, which often recommend not using such systems in winds exceeding certain speeds, typically around 20-30 mph. Always check the manufacturer's specifications and local regulations for safe operating conditions.</p>

- Q: What precautions should be taken when operating a building hoist to ensure safety?

- <p>Safety measures for using a building hoist include ensuring the hoist is regularly inspected and maintained, following the manufacturer's guidelines. Operators must be trained and certified. Load limits must be strictly adhered to, and the hoist should not be overloaded. A safety cage or gate should be in place to prevent accidental falls. Emergency stop switches should be easily accessible. Regular inspections for wear and tear, especially on cables and hooks, are crucial. Never use a hoist if it shows signs of damage or malfunction. Always secure loads properly to prevent them from shifting during transport.</p>

- Q: What are the expenses involved in buying and maintaining a building hoist?

- <p>The costs of purchasing and operating a building hoist include the initial purchase price, which can range from $10,000 to $50,000 depending on the model and capacity. Operating costs involve maintenance, which may be around $1,000 to $5,000 per year, and electricity for operation, which can vary based on usage. Additionally, there may be costs for installation, insurance, and potential repairs. Labor costs for operating the hoist should also be considered, as well as costs for compliance with safety regulations. These costs can vary widely based on location, the specific hoist model, and the scale of operations.</p>

Send your message to us

CONSTRUCTION LIFT ELEVATOR HOIST MODEL SC200/200

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords