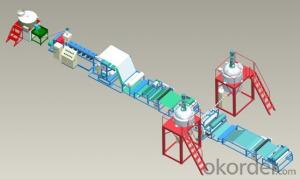

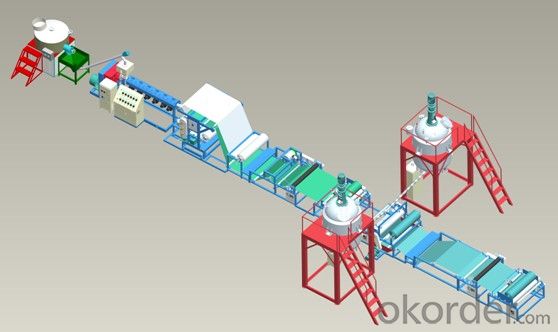

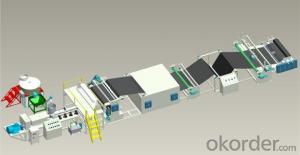

TPO Self-adhesive waterproofing membranes Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

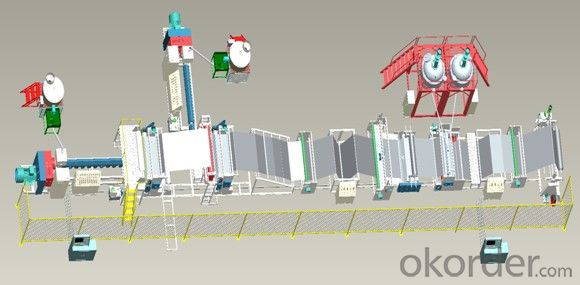

TPO Self-adhesive Waterproofing Membrane Production Line

1.Equipment Description

TPO membrane is typically based on polypropylene and EP (ethylene-propylene) rubber polymerized together using state-of-the-art polymer manufacturing technology. The TPO polymer does not contain chlorine and no chlorine-containing ingredients are added during sheet production. The TPO resin is compounded with other components including a weathering package,

fire retardants and pigments for color to create a product that can withstand the elements associated with rooftop exposure.

The membrane is comprised of TPO based top and bottom plies encapsulating a reinforcing fabric that enhances the physical properties of the sheet.

The combination of the fabric and TPO plies provide reinforced membranes with high breaking and tearing strength and puncture

2.Equipment Model

Model | Rated power (Kw) | Output (kg/h) | SizeLength×Width | Specificaiton | Production | |

Thickness(mm) | Width(mm) | |||||

SD-DG-1 |

680 |

≥1000 |

28×8.2 |

0.5-2.0 |

2000 | TPO Single (surface coating),Composite,Reinforced,Self-adhesive WaterproofingMembrane |

3.Technical Parameter

1.Host adopt advanced PLC technology, intelligent operating system.

2.Automatic heating system had taken thick-circuit,saving electricity about 40%.

3.Extruder SJ165*2 Reducer SJY375*2 Engine Power: 160KW*2

4.Mold can be with inner heating system,power is 38KW.

5.Three-Roller Device is vertical style, surface of roller was with hard chrome treatment.Power is 3KW

6.Traction Device can be used a steel roller and rubber roller with torque traction. Power is 16.

7.Winding Unit is with Inflatable winding.Power is 1.1/1.5KW.

8. Self-adhesive coating system. Power:96KW

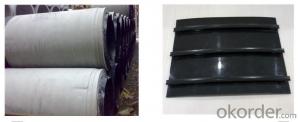

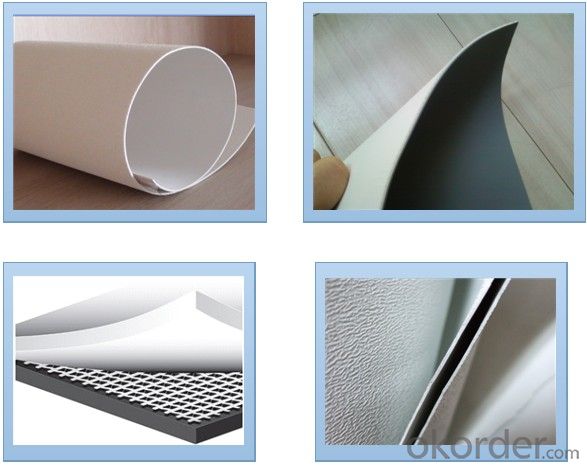

4.Products Specification

![]() Divided by product categories: non-homogeneous composite membrane (code H),

Divided by product categories: non-homogeneous composite membrane (code H),

with fiber composite backing sheet (code L),

fabric reinforced sheet (code P),

glass fiber reinforced membrane within (code G),

glass fibers increased with fiber composite backing sheet (code GL)

Length: ≥20m width: 2.1m

Thickness: 1.2mm 1.5mm 2.0mm

Color:Black,White,Grey.

5.Products Hall

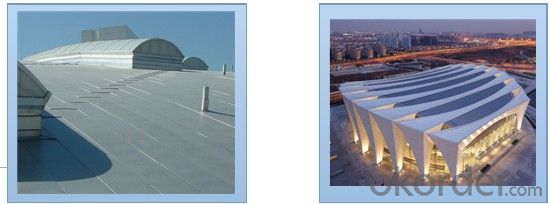

6. Application Range

Products from waterproof layers in roof,basement,steel structure roofing

,big market,large workshop,etc

Send your message to us

TPO Self-adhesive waterproofing membranes Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords