TP-MP Automatic Mini doy-pack machine packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Applications of TP-MP Automatic Mini doy-pack machine

TP- MP mini- doypack machine is an economical, fully automatic packaging machine that can complete bag opening, zipper opening , filling (filling part needs to be configured separately ), heat sealing function. Widely used in many fields such as food, chemical, pharmaceutical Industry, etc.

2. Technical parameters

| Model No. | TP-MP1 |

| Bag width | 120-300mm |

| Bag length | 120-400mm |

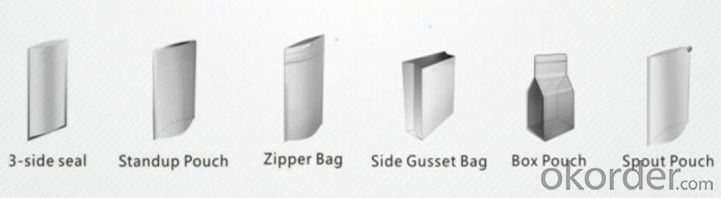

| Bag type | Stand-up bag, pillow bag, 3 side seal, zipper bag, etc |

| Power supply | 220V, 50Hz |

| Air consumption | 7.0 CFM@80 PSI |

| Pheumatic parts | PIAB Vacuum Generator, Pneumatics component airtac from Taiwan |

3. Features and Working process

- Bag loading

The Pouch magazine is adjustable for different size bags. The Bags can be loaded while the machine is in operation

- Bag detection

Multiple bag detection switches are used at various points in the cycle to ensure correct bag placement and full bag opening. Should a reject bag be detected it is ejected fromthe machine and the process continues. Rejected bags can be inspected by the operator and re-used if good.

- Bag opening

Pouches are individually removed from the cartridge with a unique combination of vacuum and pneumatic actuators. They are rotated/ transfered to the fill area and opened.

- Transtion chute

doubling as a timing bucket. product enters the transition chute while the bag is being opened below. Upon pouch detection the Chute/Funnel enters the bag and opens the gate. Product is dispensed immediately, without spillage and protecting the seal from contamination. Difficult product that easily bridges is dispensed into the pouch directly from the filler, through the "open-gate''

- Filling

During filling, pouches are held in place with our “positive-hold” gripper system. This allows for heavy weights and shock loads without altering bag Position;

- Sealing

Digitally controlled ribbed or flat constant heat seal bars give an integral attractive seal. Pouches are sealed ''in place" eliminating wrinkles, folded corners and non aligned seals

- Machine controls

System controls are fully solid state. utilizing a commercial Programmable Logic Controller [PLC] and Pneumatic. Indicator lights signal all cycle processes for easy monitoring.

- Notice:

1) The zipper part to the bag upper part should be at least 30mm, or the zipper can’t be opened.

2) The width of the pouch with closed zipper should be at least 130mm, or the zipper device will touch the 2pcs small air cylinders and the zipper can’t be opened.

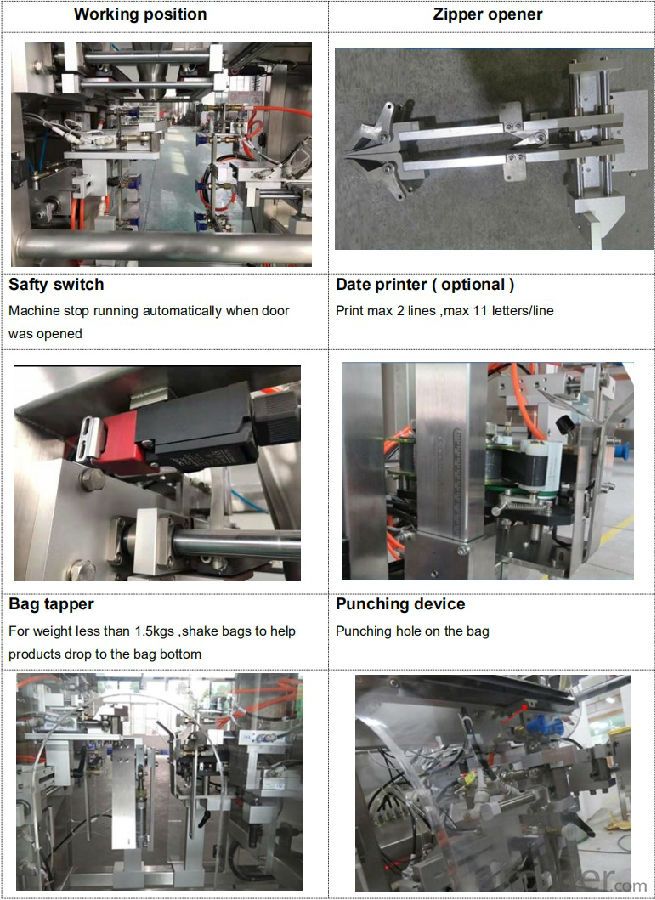

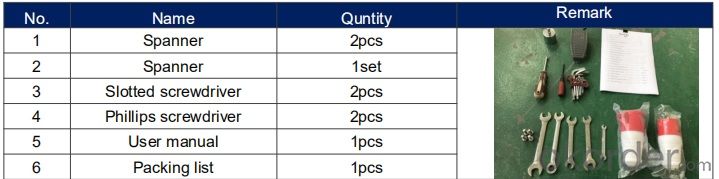

4. Detailed photos

5. Delivery and packages

6. Remarks

- TWO YEAR warranty, ENGINE THREE YEARS warranty, life-long service

(Warranty service will be honored if the damage is not caused by human or improper operation)

- Provide accessory parts in favorable price

- Update configuration

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: Bread packing machine Product features

- Bread packing machine, also commonly known as pillow type packaging machine. Among them, the suitable packing bread model has CM-320 pillow type packing machine, CM-400 pillow type bread packing machine

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It's a good mechanical design problem! In principle, yes, for example, to achieve the rated torque of the motor. He'll stop by himself! What isn't that great torque? You can zoom in on the load torque

- Q: What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- . This is the importance of after-sales service. Qingdao Xun packaging machine models, can meet the needs of all levels.

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the size of the parison forming pressure and the performance of the ceramic wall and floor tile products?Ceramic wall and floor tiles are usually formed by pressing. Domestic made for 30 tons, imported equipment has tons of suppression, 200 tons and 500 tons. In order to smooth accurate size, excellent products, must pay attention to the effect of powder properties and compression of products. That is to say, the quality of the floor tiles, billets, methods of preparation, and the quality of products and production scale and way of pressing machinery. As for pressing pressure, as the molding pressure decreases, the sintering shrinkage becomes smaller and the water absorption rate becomes smaller, the durability of the product should be improved. It should be noted that the pressure should not be too high. Excessive pressure, stress, and density increase will cause unnecessary energy consumption, and cause compressed air to expand after pressure is canceled and cause excessive spalling.

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resinUre-aformaldehyde resinsUrea formaldehyde polymer. Also called urea formaldehyde resin. The cross-linking English abbreviation UF. molding, the product is insoluble and infusible thermosetting resin, urea formaldehyde resin cured phenolic resin than the color of light, translucent resistance, weak acid and weak alkali, good insulation properties, excellent wear resistance, low price but, in case of strong acid and strong alkali decomposition, weather resistance is poor. The name Beetle. urea and 37% formaldehyde aqueous solution can be obtained by the polycondensation of linear urea formaldehyde oligomer in catalytic acid or alkali industry, with alkali as catalyst, reaction temperature of about 95, the molar ratio of formaldehyde to urea as 1.2.0, to ensure that the resin curing reaction. The first step to generate and dimethylol urea, then hydroxymethyl amino and soluble resin by further condensation, if by acid catalysis, easy to cause the product to be stored to gel. In neutral condition. The linear UF resin for ammonium chloride Curing agent can be cured at room temperature. The molding powder at 130 to 160 DEG C heat curing accelerators such as zinc sulfate, trimethyl phosphate, two oxalic acid ethyl ester can accelerate the curing process. The urea formaldehyde resin is mainly used in the manufacture of molded plastic manufacturing, daily life products and appliance parts, also can be used as adhesive, paper and fabric sheet the pulp, plywood, decorative board and so on. Because of its light color and easy coloring, products often colorful and magnificent.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- This is really not sure, it can be said that any group, as long as the packaging products are required to use packaging machinery. Most of the products are now in need of packing. So it can be said that any group.

- Q: What are the packaging machines that use temperature control watches?

- Direct heating sealing machine, blister packing machine, plastic sealing machine, heating pot, oven, toaster and so on

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

Send your message to us

TP-MP Automatic Mini doy-pack machine packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords