TP-A Series Multihead Weigher food usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. General descriptions of the TP-A Series Multihead Weigher

It is suitable for weighing leisure foods such as candy, seeds, jelly, pet foods, puffy foods, pistachio, peanuts, nuts, raisins etc. and big shell nuts, hardwares, dried fruits, frozen foods, snack foods, meatballs and so on.

2.Mains Features

- Adopt high precision and high accurate loadcell of famous brand, resolution is improved up to 2 decimal;

- Program recovery function can reduce operation failures and support multi-segment weight calibration;

- No products auto pause function can improve weighing stability and accuracy;

- 100 programs capacity can meet various weighing requirements and user-friendly help menu contributes to easy operation;

- Linear amplitude can be adjusted independently in the running;

- Many languages available for global markets.

- Sanitation with 304S/S construction ;

- Rigid design for vibrator and feed pan make feeding strictly correct ;

- Quick release design for all the contact parts

- Grand new modular control system .

- Adopt stepless vibrating feeding system to make products flow more fluently .

- Make mix different products weighing at one discharge .

- Parameter can be freely adjusted according to production .

3. Technical parameters

| Model | TP-A10 | TP-A14 |

| Weighing range | 10-1000g | 10-1500g |

| Accuracy | X(0.5) | X(0.5) |

| Max speed | 65P/M | 120P/M |

| Hopper volume | 1.6/2.5L | |

| Control panel | 7" Touch screen | |

| Options | Dimple plate/Timing Hopper/Printer/Reject Device | |

| Driving system | Step motor | |

| Power Requirement | 220V/1000W/ 50/60Hz / 10A | 220V/1500W/ 50/60Hz / 10A |

| Packing dimension(mm) | 1620(L)*1100(W)*1110(H) | 1700(L)*1100(W)*1265(H) |

| Gross weight | 380kg | 490kg |

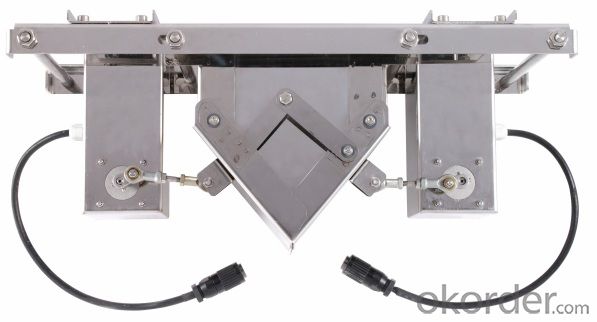

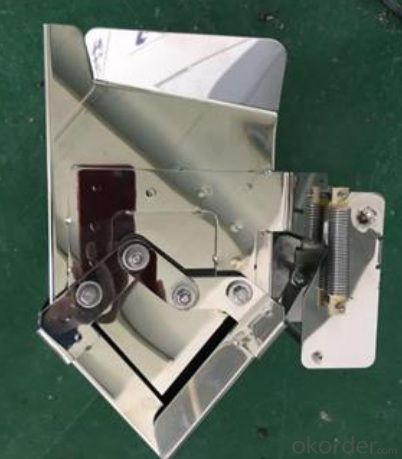

4. Detailed photos

-Grand new modular control system, high stability, high accuracy, can be accurate to 0.1g.

- Multi languages on touch screen for choice

- Weighing hopper 4.5L SUS material, full mirror polished, it meets food grade, and very easy for cleaning

-Linear vibrator

1) SUS material, full mirror polished, it meets food grade, and very easy for cleaning.

2) Quick release design, easy for fixing and cleaning.

5. Packages and delivery

6. Remarks

- TWO YEAR warranty, ENGINE THREE YEARS warranty, life-long service

(Warranty service will be honored if the damage is not caused by human or improper operation)

- Provide accessory parts in favorable price

- Update configuration and program regularly

- Q: What is the design basis of automated packaging?! Just for today!

- Greatly improve the degree of automation of process flowA few years ago, automation technology accounted for only 30% of the design of packaging machinery, now has accounted for more than 50%, a large number of micro computer design and mechanical and electrical integration control. To improve the packaging machinery automation, one is to increase productivity; the two is to improve the flexibility and agility equipment; three is to improve the ability of packaging machinery to complete the complex action, namely the manipulator to complete the packaging process. Such as chocolate packaging has been achieved, with mechanical hand instead of the original manual. Automatic design of packaging machinery has the following two main characteristics:

- Q: Bread packing machine Product features

- Bread packing machine, also commonly known as pillow type packaging machine. Among them, the suitable packing bread model has CM-320 pillow type packing machine, CM-400 pillow type bread packing machine

- Q: What is the price of a small jujube packing machine?

- Mainly see what some requirements, automatic metering packaging or vacuum packaging machine, after understanding can determine the price.

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: What is the name of the paper used in packing machine parts and yellow?

- Vapor phase rust proof paper is coated with vapor phase corrosion inhibitor on the base of antirust base paper (surface like kraft paper, but with chloride ion and sulfate ion limit requirement)

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- Take the food packaging machine for example, if only from the hardware, then you can ask when you buy the degree of automation, semi-automatic or fully automatic, the use of steel ah,

- Q: What is the working principle of the pillow packing machine?

- Some packaging machinery manufacturers, many varieties of products, in the purchase of packaging machines, I hope a device can pack all their own varieties

- Q: What are the packaging machines that use temperature control watches?

- A lot of heating machines have to use thermostat

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Different conceptsCompression molding refers to hot forming: mainly for thermoplastic materials (sheet), the use of hot forming machine, Blister molding, I think it should also be considered as a branch of hot stamping, vacuum or high-pressure gas will be used to assist. Hot pressing sheet forming a relatively small depth, relatively simple structure, low precision products, such as packaging materials, plastic pallets, plates in the dishes and so on. There are also forming plate pressing molding (lamination)

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Hygienic standard for polyethylene terephthalate resin for GB 13114 food containers and packaging materialsGB, 13113-1991. Hygienic standard for polyethylene terephthalate molded articles for food containers and packaging materials

Send your message to us

TP-A Series Multihead Weigher food usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords