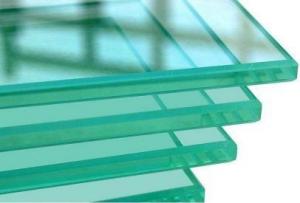

F Green Toughened glass Security features

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Provide QAIC/CN attestationProvide ISO 9001-2008 CCC attestation

Provide super quality and competitive price

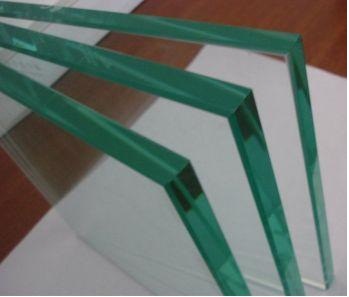

Tempered, toughened glass is heated to the temperature that near soft point, the surface resulting from the rapid cooling homogeneity has powerful compressive stress, the glass is double increase in all mechanical performance indexes. The surface stress value for tempered glass is more than 90Mpa and 24-69Mpa for the semi-tempered or toughened glass.

The feature of tempered glass:

High intensity: The bending strength of tempered glass is 3-4 times than common glass and the shock strength is 6-7 times than common glass.

Heat stability: Tempered glass has good thermal stability can withstand a range in 300 ℃temperatures, which is 3 times than common glass.

Security: Because of the stress layer of tempered glass, thus has strong shock resistance, make its not easy to damage, and it will not cause greater harm to human body when the broken glass after obtuse angle formed by small particles.

Toughened glass is also called heat enhancement or tempered glass, its strength is 1.5 to 2 times of ordinary annealed glass, thermal stability is twice as common annealed glass, toughened glass of flatness is approach to ordinary annealed glass and far superior to toughened glass, its biggest advantage is that there is no explosive's ills, but once causing damage, it still produces larger pieces and after its damage easily hurt the body, but its security is better than ordinary annealed glass.

Maximum processing size: 11000 mm * 3000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 4 mm to 25 mm

Insulating Glazing

A. All glass can be processed before assembly

B. Glass transfer onto the glass loading machine

C. Edge coating removing of coated glass

D. Wash and clean strictly

E. Automatic bending for air spacer

F. Automatic molecular sieve filling

G. Automatic butyl rubber applying

H. Automatic framing

K. Automatic scanning positioning

L. Automatic double sealing

M. Transfer by sucking disc

N. Conner finishing

O. Glass on the shelves till solidification

P. Customized wooden cases according to the size of glass

Q. Transfer the glass into the specific wooden cases

R. Leading Time:10 days for an average area of 1000 square

meters tempered glass

S. Trade terms: FOB and CIF.

T. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

U. The container loading after the package checking

- Q: i want to build a glass reptile terrarium with the measurements 4 foot in length x 2 foot in width x 1 1/2 foot high for 100$ or under need to know where to buy the glass for cheep (8mm thick) and hoe to seal it with no wood just like one i would buy at a pet store and how to make the mesh lid please reply asap thanks

- This is most likely a build up of limescale. You can wash it with hot soapy water and scrub the glass with a scourer to get the limescale off. Make sure that you rinse it very thoroughly. It is also worth washing it in a very weak bleach solution to just in case the animal living in there before had some sort of disease, you won't want your dragon catching anything. You will need to rinse it thoroughly at least 3 times to make sure you don't leave any bleach in there after though.

- Q: I am about to build an all-glass aquarium, the glass edge-joined with silicon. I have seen it done a number of times and am confident I am able to do it. The finished tank size will be 150cm long, 60cm tall and 50cm deep. I intend to brace the front and back as well as the two sides and also put two cross braces running front to back at the top of the tank at 50cm and 100cm intervals. Does anybody know how I should calculate the glass thickness or, alternatively, does anyone out there have a tank of a similar size they could tell me what the dimensions of theirs is.Thanks

- This Site Might Help You. RE: Home built glass aquarium - how thick should the glass be? I am about to build an all-glass aquarium, the glass edge-joined with silicon. I have seen it done a number of times and am confident I am able to do it. The finished tank size will be 150cm long, 60cm tall and 50cm deep. I intend to brace the front and back as well as the two sides and also put...

- Q: What are the equipment to build a glass factory?

- Tempered glass factory generally has the following equipment: First, cutting machine. Second, milling machine (unilateral, bilateral grinding), shaped machine, drilling machine, and so on. Third, the steel furnace four, plastic pre-pressure line, autoclave. Fourth, the hollow production line, which is more complete construction of glass production machinery.

- Q: Why is the glass transparent? What is extended is water, ice and so on transparent things Please explain from the principle, simply, you do not ask Glass reflected light and other objects reflect the light is nothing different, Why some objects can be transparent, and some objects are not transparent

- An important reason: a solid matter, if it is seen from the inside of the atom, it is actually empty. Because in the interior of the atom, the nuclei and the volume of electrons add up to less than one millionth of the atomic volume. Moreover, there is no evidence that the nucleus and electrons can not be photographed through! So, transparent is normal!

- Q: I have a chinese water dragon. He is still a baby but I'm looking to build him a bigger cage as he will grow to possibly three feet in length. I've searched the net for ideas on his cage and I'd like to use glass or plexi-glass on the sides and front of the cage. Even though I've looked at all the youtube videos I can find and any free plans I can find, I can't find a good way to build doors with glass, or plexi-glass, in them. I might just go with a sliding door but I'd prefer a door or two similar to a cabinet door. The opening is most likely going to be about 4 feet high. I also can't figure out how to attach the side, glass/plexi-glass, panels.I have basic tools but I don't consider myself a great carpenter. In other words, it needs to be simple.Any suggestions/help would be wonderful.

- I would go with the plexi. That way you could make a wooden frame (or metal if you wanted) and then just drill the plexi (very slowly as to not crack it) and then screw it into the frame that you have made. Once you have that done you can focus on the doors. I would suggest making them in the same fashion. Once you have everything assembled you should seal it up. For this i suggest using "aquarium silicone" (use this because it is animal safe). You can get it any Lowe's or Home Depot (it should be near the paints and glues). *NOTE* -If you plan on building this way it is very important to remember that you need air holes or screening so the animal can breathe. For this you can either drill more holes in the plexi, or use some sort of screen for the roof- I hope this has given you some more ideas on how to make an enclosure that will not only house your larger animal, but also look decent doing it :)

- Q: The general specification is to ask the length and width of the glass at the time of shipment and the length of the cut, the number of cuts, and the method. In the question of whether the two companies in the data of the two materials can be provided? Behind can be chase points.

- Do not know the owner asked the sound effects are not specific values, in general, insulating glass regardless of steel or broken bridge aluminum alloy sound insulation effect is very good, if you consider the quality of the problem or broken bridge aluminum alloy more practical but cost is relatively high, The deformation of the aging problem is more prominent, and broken bridge aluminum alloy processing accuracy is much higher than the plastic, the size of precision is also high for the civilian low-grade can choose steel, in the high-grade use of broken bridge aluminum alloy, for Office buildings such as the best choice of broken bridge aluminum alloy is ideal. I hope my answer is helpful to you!

- Q: What is the introduction of new glass advertising slogan

- New glass is your first choice

- Q: In addition to the service industry, what other work?

- What will you do? Everyone has his own specialty

- Q: What is glass called glass?

- Modern living room, sound insulation is good, has become one of the important factors to measure the quality of housing.Using Saflex? PVB interlayer of laminated glass can block the sound waves, to maintain a quiet and comfortable office environment. Its unique filter UV function, Both to protect people's skin health, but also make the home of precious furniture, exhibits, etc. to get rid of faded doom. It can also weaken the transmission of sunlight, reduce cooling energy consumption. The disadvantage of laminated glass is that the glass is soaked in water, the water molecules more easily into the glass sandwich, the glass surface blurred. There are many advantages of laminated glass, used in home decoration will also have unexpected good results.As many families of the door, including the kitchen door, are made of frosted glass materials. Cooking the kitchen fumes easily accumulated in the above, if With the laminated glass instead, it will not have this trouble. Similarly, the home of a large area of ??the glass interval, born to the child is a security risk, if the use of laminated glass, the parents can be greatly assured. Laminated glass is ruptured and may break under heavy hammer, but the whole piece of glass remains intact, and pieces and sharp pieces are still clogged with the intermediate film. When the glass is broken, the pieces are not scattered and used In the car and other means of transport. Tempered glass requires a greater impact force is broken, once broken, the whole piece of glass burst into numerous fine particles, the framework of only a little broken glass. Ordinary glass hit a broken, the typical crushing situation, resulting in many long strip of sharp mouth fragments. When the broken glass is broken, the mirror-shaped debris surrounds the hole and leaves more glass fragments around the penetrating point. The wire breaks in different lengths.

- Q: Curtains can not pull the first ten centimeters, glass cover, what way to cover

- If the track is not the end can be considered for one, very economical

Send your message to us

F Green Toughened glass Security features

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords