Tinplate For Kitchenware, SPCC/MR, Secondary Grade

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

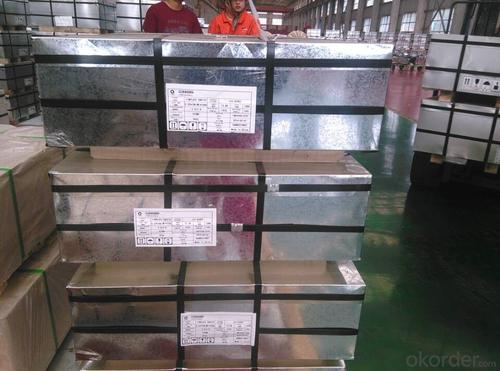

4. Our factory photo & equipments

5. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

6. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: Can tinplate be reused?

- Yes, tinplate can be reused. It is a highly recyclable material that can be melted down and reprocessed to create new tinplate products.

- Q: Can tinplate packaging be used for toy products?

- Yes, tinplate packaging can be used for toy products. Tinplate is a durable and versatile material that can be shaped into various sizes and designs, making it suitable for packaging toys. It provides an attractive and protective packaging solution, ensuring the safety and preservation of toy products.

- Q: How is tinplate tested for quality and durability?

- Tinplate is tested for quality and durability through various methods such as visual inspection, coating weight measurement, corrosion resistance tests, and mechanical tests. Visual inspection ensures that the tinplate has a consistent surface finish, free from any defects or imperfections. Coating weight measurement is conducted to determine the thickness of the tin coating, ensuring it meets the required specifications. Corrosion resistance tests evaluate how well the tinplate withstands exposure to various corrosive environments. Mechanical tests assess the strength, hardness, and ductility of the tinplate, ensuring it can withstand bending, forming, and other manufacturing processes without any issues. These testing methods collectively ensure that the tinplate meets the desired quality and durability standards.

- Q: Can tinplate be used for household appliances?

- Yes, tinplate can be used for household appliances. Tinplate is a type of steel coated with a thin layer of tin, which provides corrosion resistance and enhances the appearance of the metal. This makes it suitable for manufacturing various household appliances such as cans, containers, kitchen utensils, and even small electrical appliances.

- Q: How does tinplate perform in terms of printability?

- Tinplate performs exceptionally well in terms of printability. Its smooth surface allows for high-quality printing with vibrant colors and fine details. Additionally, the tin coating provides excellent ink adhesion, ensuring sharp and crisp prints.

- Q: Can tinplate be used for packaging alcoholic beverages?

- Yes, tinplate can be used for packaging alcoholic beverages. Tinplate is a commonly used material for beverage cans, including alcoholic beverages, due to its durability, resistance to corrosion, and ability to preserve the quality and flavor of the product.

- Q: What are the different types of tinplate surface treatments?

- There are several types of tinplate surface treatments, including electrolytic tinplate (ETP), tin-free steel (TFS), blackplate, and lacquered tinplate.

- Q: How has tinplate evolved over the years?

- Tinplate has evolved significantly over the years with advancements in production techniques and technology. Initially, tinplate was made by hand, resulting in inconsistent quality and limited production. However, with the development of mechanized processes, tinplate production became faster, more efficient, and cost-effective. Additionally, improvements in tin coating methods have enhanced the durability and corrosion resistance of tinplate. Nowadays, tinplate is produced using high-speed mills and advanced coating technologies, ensuring consistent quality, customization options, and increased market demand.

- Q: What are the main challenges in the tinplate industry?

- The main challenges in the tinplate industry include fluctuating raw material prices, increasing competition, sustainability concerns, and maintaining product quality and innovation. Additionally, the industry also faces challenges related to supply chain management, regulatory compliance, and meeting changing customer demands and preferences.

- Q: How is tinplate coated on both sides?

- Tinplate is coated on both sides by immersing the steel sheet in a bath of molten tin. This process, known as hot-dipping, ensures that both sides of the steel sheet are evenly coated with a layer of tin, providing protection against corrosion and enhancing its appearance.

Send your message to us

Tinplate For Kitchenware, SPCC/MR, Secondary Grade

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords