Tinplate for food cans and chemical cans with good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

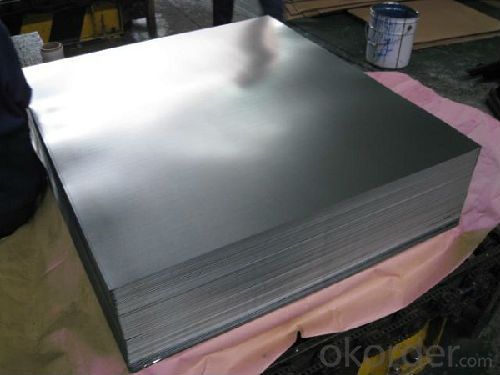

Prime Quality Tinplate Sheets Details

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Specifications:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q: What are the common uses of tinplate?

- Tinplate is commonly used in the packaging industry for making cans, containers, and lids for food and beverages. It is also used in the production of aerosol cans, paint cans, and metal closures. Additionally, tinplate is used for making various household items such as kitchen utensils, storage boxes, and tin toys.

- Q: How is the thickness of tinplate measured?

- The thickness of tinplate is typically measured using a specialized instrument called a micrometer. This handheld device allows for precise measurement of the tinplate thickness by exerting pressure on the surface and providing an accurate reading in millimeters or inches.

- Q: Can tinplate be shielded?

- Two kinds of materials of tinplate and paktong in general: tinplate is cheaper, weldability is good, but easy to rust, and relatively soft, compared to a large shield narrow cover will have problems. Alpaka relatively high prices, the weldability is poor, but can provide performance through tin, relativelyhard. At present, the use of shielding in the mobile phone, these two materials are more, but taking into account the cost or priority of tinplate

- Q: Can tinplate packaging be used for chemical products?

- Yes, tinplate packaging can be used for chemical products. It is a common choice for storing and transporting various chemicals due to its durability, resistance to corrosion, and ability to provide a protective barrier against external factors. Tinplate packaging is also compatible with different closure systems, making it suitable for a wide range of chemical products.

- Q: What are the main applications of tinplate in the music industry?

- Tinplate is primarily used in the music industry for the production of cans for storing and preserving musical instruments, such as drums and cymbals. It provides a durable, corrosion-resistant and lightweight solution for packaging and transporting these instruments, ensuring their protection and longevity. Additionally, tinplate is also used for manufacturing components of musical instruments, such as reeds for woodwind instruments or small parts for stringed instruments, due to its malleability and ability to create intricate shapes.

- Q: What are the advantages of using tinplate for packaging?

- Tinplate offers several advantages for packaging. Firstly, it provides excellent protection against moisture, air, and light, which helps in preserving the quality and freshness of the packaged product. Secondly, tinplate is highly durable and can withstand rough handling during transportation and storage. It also offers resistance against corrosion, ensuring the longevity of the packaging. Additionally, tinplate is easily recyclable, making it an environmentally friendly choice. Lastly, tinplate can be shaped into various sizes and designs, allowing for attractive and customized packaging options.

- Q: Can tinplate be used for pharmaceutical blister packaging?

- Yes, tinplate can be used for pharmaceutical blister packaging.

- Q: Can tinplate be formed into different shapes and sizes?

- Yes, tinplate can be easily formed into various shapes and sizes due to its malleability.

- Q: What are the common industry standards for tinplate?

- The common industry standards for tinplate include specifications for the tin coating weight, the base metal thickness, surface finish, and the adhesion of the tin coating. These standards ensure consistency and quality in the production of tinplate, allowing for its effective use in various industries such as packaging, automotive, and construction.

- Q: What are the recycling processes for tinplate?

- The recycling processes for tinplate typically involve collecting and sorting the tinplate materials, removing any contaminants, such as paper or plastic coatings, and then shredding the tinplate into small pieces. The shredded tinplate is then melted in a furnace to separate the steel from the tin. The steel is recovered and can be used to make new tinplate products, while the tin is commonly reused in various applications or sold as a raw material.

Send your message to us

Tinplate for food cans and chemical cans with good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords