Tinplate Beer Cans - Electrical Tinplate JIS G3303 Standard for Food and Industrial Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter.

It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

TINPLATE SPECIFICATION

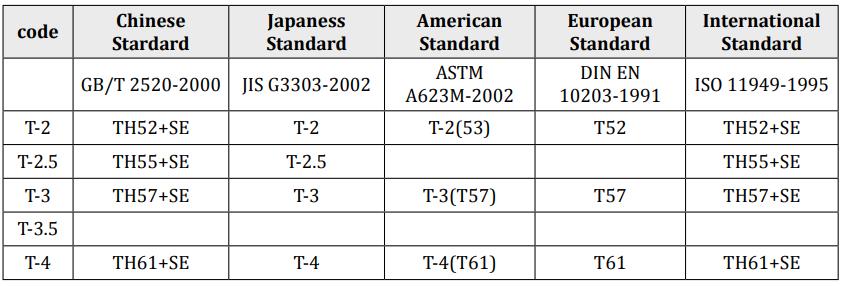

1.Reference standard: GB/T 2520-2000,JIS G3303-2002 and DIN EN 10203-1991

2. Raw material: MR and SPCC

3.Thickness: 0.13 to 0.5mm

4.Width: 600-1050mm

5.Coil diameter: ID 420mm or 508mm

6.Temper: T1~T5,DR8~DR10

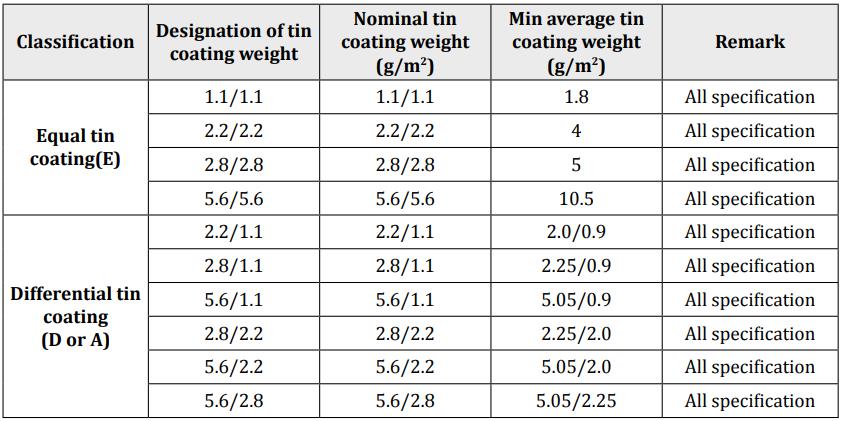

7.Tin coating: 1.1g~11.2g, We can produce according to customer's requests.

8. Applications: paint, chemical and other usage can make battery, electric cable and other industries

9. Package: anti-rust paper, corner protected. Sheets or coils according customer's requests

STANDARD

SURFACE

| Marks | Surface state | Characteristics |

| B | Bright rough | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip featuring certain oriented rubstone figure. |

| RR | St hStone rough | Glazed surface obtained after melting treatment of electrotinned raw material strip featuringg p g certain oriented rubstone figure. |

| S | Silver rough | Glazed surface obtained after melting treatment of electrotinned raw material strip with rough matt surface. |

COATING

APPLICATION

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Q:How does tinplate perform in terms of moisture resistance?

- Tinplate performs exceptionally well in terms of moisture resistance. The tin coating on the steel substrate acts as a barrier, preventing moisture from coming into contact with the metal and causing corrosion. This makes tinplate highly suitable for packaging applications where moisture protection is crucial, ensuring the preservation and integrity of the contents.

- Q:Can tinplate be used for packaging wine or spirits?

- Yes, tinplate can be used for packaging wine or spirits. Tinplate is a type of steel coated with tin, which provides excellent protection against corrosion and can preserve the quality and flavor of the wine or spirits. Additionally, tinplate is lightweight and easy to shape, making it a suitable choice for packaging various alcoholic beverages.

- Q:What details should I pay attention to when purchasing tinplate packing boxes?

- Many small processing plants or small factories can accept the buyer's bargaining, but the iron is really not flattering. In fact, the market is very transparent iron materials, buyers do not mean that the more the better the bargaining, but to understand the market, do not bargain.

- Q:How does tinplate contribute to the overall reusability of packaging?

- Tinplate contributes to the overall reusability of packaging due to its durable and long-lasting nature. It can be easily cleaned and reused multiple times without losing its structural integrity, making it an ideal material for packaging that can be used again and again. Additionally, tinplate is highly resistant to corrosion, ensuring that the packaging remains in good condition for extended periods. Its reusability helps reduce waste and promotes sustainable practices in the packaging industry.

- Q:How does tinplate contribute to the preservation of photographic equipment?

- Tinplate contributes to the preservation of photographic equipment by providing a durable and corrosion-resistant material for the construction of camera bodies, lens barrels, and other sensitive components. Its protective coating prevents the equipment from rusting or deteriorating over time, ensuring the longevity and functionality of the photographic devices.

- Q:How long does tinplate take to corrode?

- The time it takes for tinplate to corrode can vary depending on various factors such as the environment, exposure to moisture, and the presence of corrosive substances. However, tinplate is generally known for its excellent corrosion resistance, and under normal conditions, it can take several years or even decades before significant corrosion occurs.

- Q:How does tinplate ensure the freshness of pet food?

- Tinplate ensures the freshness of pet food by providing an airtight and durable packaging solution. This material is highly resistant to corrosion and helps to prevent external factors such as moisture, light, and oxygen from entering the packaging and spoiling the food. Additionally, tinplate offers a long shelf life for pet food, preserving its nutritional value and flavor until it is consumed by pets.

- Q:How does tinplate affect the overall barrier properties of packaging?

- Tinplate enhances the overall barrier properties of packaging by providing a protective layer that effectively prevents the transfer of oxygen, moisture, and light. This barrier helps to preserve the quality, freshness, and shelf life of the packaged product, ensuring its integrity and safety.

- Q:Can tinplate be used for beverage cans?

- Yes, tinplate can be used for beverage cans. Tinplate refers to steel coated with a thin layer of tin, which provides excellent corrosion resistance and makes it suitable for packaging food and beverages. Tinplate is commonly used in the production of beverage cans due to its durability, versatility, and ability to preserve the taste and quality of the contents.

- Q:Can tinplate be used for kitchenware?

- Yes, tinplate can be used for kitchenware. Tinplate is a type of steel coated with a thin layer of tin, which provides protection against corrosion and enhances its aesthetics. It is commonly used for making cans, containers, and other kitchen utensils like bowls, trays, and cooking pans. Tinplate is durable, easy to clean, and resistant to rust, making it suitable for various kitchen applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tinplate Beer Cans - Electrical Tinplate JIS G3303 Standard for Food and Industrial Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords