Anticorrosive Thermo Wood-Heat Modified Lumber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1x20' FCL m²

- Supply Capability:

- 1000 CBM m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

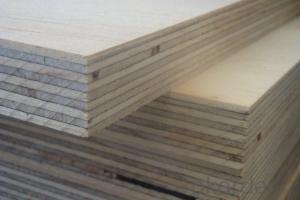

Specifications of the Thermo Wood-Heat Modified Lumber

| Species | Pine, Spruce, Ash |

| Size | as per request |

| Treatment | vacuum heat treated |

| Moisture | 5%-12% |

| Features | waterproof, sun-proof,Rot-proof, Fungi-proof and insect-proof |

Application of the Thermo Wood-Heat Modified Lumber

Sauna room furniture and decoration; outdoor use, good materials to make outdoor flooring,

fence, wood house, outdoor furniture etc.

Instruction of the Thermo Wood-Heat Modified Lumber

Wood thermal modification is based on heating wood at high temperatures,

160-220. During treatment no chemicals are used, only a water vapour as shieding gas.

Wood properties of the Thermo Wood-Heat Modified Lumber

The properties of heat modified wood depend from treatment process: temperature and treatment

time. Temperature has greater influence on many properties than time. During treatment wood

color change into brown or dark brown throughtly. The color is not stable for UV light, unless the

surface is treated with UV resistant coating.

Improvement of the Thermo Wood-Heat Modifies Lumber

The biological resistance in a laboratory test showed very good durablity depending on the

treatment temperature and time. Astreatment is made through and through, a wood durability

and stablity is assured even when thermo modifies wood surface is damaged during usage.

The following pictures for your reference

- Q: Will the balcony of the wood preservative wood which materials, what are their characteristics?

- Installation instructions: First, at the construction site, antiseptic wood should be stored in the air, should be avoided as far as possible direct exposure to the sun; Second, in the construction, should be used as far as possible the existing size of preservative wood, for cutting, drilling, etc., must use CCA preservative remediation to ensure the life of wood preservative;

- Q: Antiseptic wood pots waterproof?

- Antique wood flower pot is waterproof. Antiseptic wood, is the ordinary wood after adding artificial chemical preservatives, so that it has anti-corrosion, moisture, anti-fungal, pest control, mildew and waterproof and other characteristics. Can be directly exposed to the soil and humid environment, often used in outdoor flooring, engineering, landscape, wood preserves, etc., for people to rest and enjoy the natural beauty, outdoor flooring, landscape, wooden swing, recreational facilities, , By the horticultural designers of all ages, but with the development of science and technology, anti-corrosion wood has been very environmentally friendly, it is also often used in interior decoration, flooring and furniture, interior decoration designers are also very fond of preservative wood.

- Q: Suspension Bridge above the shop's anti-corrosion wood Hanzhong where to sell?

- Yes, to the stainless steel frame on the hole with the first anti-corrosion wood block fixed, above the shop anti-corrosion wood! Or anti-corrosion board with stainless steel frame connection is not strong! I wish you a happy life

- Q: Antiseptic wood why so environmentally friendly

- Antiseptic wood is processed into wood after the installation of sealed pressure corrosion tank, with a vacuum pressure to the anti-corrosion agent into the wood inside the preservative infiltration into the wood cell organization, can be closely combined with the wood fiber, so as to achieve the purpose of corrosion. The use of anti-corrosion wood in the decoration of the courtyard can prevent the appearance of outdoor furniture in the open-air use when the corrosion situation, in creating a warm atmosphere at home, than the traditional brick, stone, iron and other common materials much better, Concept, close to nature. The following are the same as the " Why is this? Mainly after the use of anti-corrosion technology of wood, like the commonly used Pinus sylvestris, South pine, Douglas fir and other anti-corrosion wood can effectively prevent mold, termites, microbial bruises, effectively inhibit the treatment of wood moisture content changes, Reduce the degree of cracking of wood, the wood life extended to 40 to 50 years, greatly easing the current lack of wood on the market situation. Preservative residue per cubic meter of anti-corrosion material is very low, high environmental protection. Pressurized anti-corrosion material is undoubtedly reliable, durable, beautiful green building materials.

- Q: Home decoration would like to use anti-corrosion wood to do the windows below the decorative layer, will leak it? What is the life of wood preservative? Northeast for the kind of preservative wood? Thank you

- Antiseptic wood, is the ordinary wood after adding artificial chemical preservatives, so that it has anti-corrosion, moisture, anti-fungal, pest control, mildew and waterproof and other characteristics

- Q: Red rice eucalyptus antiseptic wood red eucalyptus wood eucalyptus wood how many square meters

- It depends on what your specifications. There are different geographical prices are not the same. Fine Luo industrial anti-corrosion wood manufacturers warm tips you.

- Q: Imitation wood, plastic wood, wood preserving the difference between the three, do not Baidu Encyclopedia of the answer, I want from their craft to the advantages and disadvantages of analysis, seeking professional answers. (Some people say that cement is someone, it was classified as plastic, this is how is it?

- Imitation wood, you can use a variety of materials imitation wood, for example, I use stainless steel imitation wood, cement imitation wood imitation tree, glass steel imitation wood imitation tree.

- Q: The house long-term anti-corrosion wood wood what harm

- It depends on what kind of, and the general harm to the human body is not. Like furniture and outdoor flooring are done anti-corrosion treatment, the human body is not harmful. However, it should be noted that the preservative arsenic in the composition, if too high will cause death, arsenic is a chronic poison, it is said that Napoleon is arsenic poisoning dead.

- Q: Outdoor garden road pavement preservative wood (antiseptic wood specifications 120 * 40) when the wood keel how high

- 1, outdoor garden road pavement preservative wood, antiseptic wood specifications 120 * 40, the height of the wood keel according to the requirements of construction drawings to determine.

- Q: What kind of wood can the anti-corrosion of those who can not.

- Because of its unique anti-corrosion process, all the architectural works can be long-term preservation.

Send your message to us

Anticorrosive Thermo Wood-Heat Modified Lumber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1x20' FCL m²

- Supply Capability:

- 1000 CBM m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords