Anticorrosive ACQ Treated Fir Wood

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1x20' FCL m³

- Supply Capability:

- 20000M³ Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details of the ACQ Treated Fir Wood

| Species | Pine |

| Size | Be customized as per request |

| Preservative Type | ACQ |

| Moisture content | 8--12% |

| Usage | most outdoor using |

| Grade | A Grade |

| package | Standard exporting package |

Instruction of the ACQ Treated Anticorrosive Pine Wood

ACQ(Alkaline Copper Quaternary) mainly consists of alkaline and cooper oxide which is widely used in the

outdoor building projects. At present, it’s the most environmental antiseptic lotion lin the world. The wood

products treated with ACQ is durable and prolonging the life of usuage.

Specials of the ACQ Treated Fir wood

Special 1: Treated by high quality ACQ,

Special 2: make the timber from the damage of the insects

Special 3: about 50 years of serving life.

Special 4: anticorrosive from the outside environment.

Special 5: Eco-firendly, no harm to the air, the plants, the humans.

Special 6: advanced flame retardent techinics

ACQ Treated Fir wood is very suitable for outdoor using.

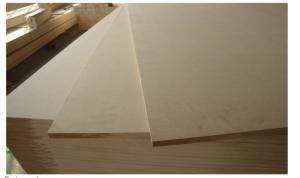

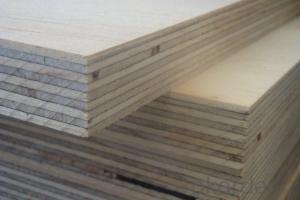

The following pictures for your reference

- Q: The first floor is very humid, and white walls in some places are moldy, I think both sides of the wall is not painted wall paint, direct use of anti-corrosion board, because done want to immediately live, so do not want to use paint, Knowledgeable people to help answer, thank you!

- Master said; brush over can live in it. In fact, very good, and there is no taste. Master also said that they have been in use, is the "blue ocean water-based coating"

- Q: Shop antiseptic wood wages how much a square meter

- Camphor pine antiseptic wood 2500-3000 / cubic meter ecological wood 3000-4000 outdoor flooring Pinus sylvestris antiseptic wood laying the cost of basic materials about 80-120 yuan / square offer about 150-200 / square

- Q: Antique wood on the balcony is always how to do the oil

- Pinus sylvestris is China's resource stability, cost-effective for the anti-corrosion wood species (specifically see my company finishing the timber file), Pinus sylvestris has a significant drawback is that varying degrees of containing pine oil, its production must be degreased Technical processing. As the price is low, the texture is clear, the wood diameter easy to process and so on, by the consumer favorite, in the decoration market still occupies no small share. Degreasing technology is through a special closed drying room, 80 degrees in the high temperature and humidity for 192 hours, so that the oil within the camphor pine with the evaporation of water at the same time and overflow, in order to achieve the purpose of basic degreasing. After the degreasing, drying of Pinus sylvestris, its geometric size is stable, greatly reducing the risk of deformation, cracking, in the hot sun does not take the oil, not degreased Pinus sylvestris preservative wood, will seriously affect the product appearance and finishing , In the humid environment will be mildew, while the overflow oil mouth will be eating organic matter bacteria, insect erosion of wood breakthrough in the use of the beginning will gradually decay. Only through the degreasing of wood after drying, in order to ensure the penetration of preservatives and drug loading, to achieve the quality of national anti-corrosion timber standards. My company's B technology anti-corrosion technology, the price of 3400-3600 side.

- Q: Antiseptic wood why so environmentally friendly

- Wood preservative is the 20th century since the development of the discipline, the success of the development of each type of preservatives are in the government's huge financial support, in countless wood, chemical, biological and other fields of scientists through repeated experiments, in particular, to go through Ten years of weatherability, negative effects and other experimental links to be completed (at present there is no single domestic companies can have this financial and technical strength in the short term to complete), after the world's wood scientists nearly a hundred years of efforts , Before the development of today's widely used anti-corrosion wood. Because the anti-corrosion wood through the physical and chemical methods, so as to achieve the anti-corrosion, mildew, moth, anti-termite effect, but also improve the stability of the wood, in contact with moist soil or hydrophilic effect is particularly significant, Climate environment used for 15-50 years or more unchanged. The life of the antiseptic wood has reached 3 to 5 times that of the untreated wood, saving the wood very much. The picture shows the wood rot and shake the building structure, but also the rest of the building in the wood were wasted. The picture shows the wood moldy and difficult to put into use. Woods that do not have anti-corrosion function also lead to termites, which are insects that eat wood, appear in groups, and sometimes ambush in poor wood is also a disaster. The above phenomenon can be used to prevent the use of preservative wood, so that the conservation of forest resources, but also to make people's lives can be this kind of natural material

- Q: How to make the old wood made of rust wood?

- for people to rest and enjoy the natural beauty, outdoor flooring, landscape, wooden swing, recreational facilities, , By the horticultural designers of all ages, but with the development of science and technology, anti-corrosion wood has been very environmentally friendly, it is also often used in interior decoration, flooring and furniture, interior decoration designers are also very fond of preservative wood.

- Q: Antique wood box how to do waterproof

- Anti-corrosion flower box, do not how to do waterproof. Because the preservative wood itself is processed and processed, not afraid of water wood. You only need to do the drain function at the bottom.

- Q: I would like to ask China's imports of anti-corrosion wood customs code, customs duties, value-added tax, and what documents for import?

- Reference to the tax number 44130000.00 Reinforced wood (into pieces, plates, strips or shaped) Tariff 6%, VAT 17% Import inspection, customs clearance

- Q: China's top ten brands of anti-corrosion wood which?

- I only remember the first two, the first is the loose edge, the second is Yu Jing, these two are the old brand, big brand. Hope to help you, thank you!

- Q: How to paint the wood

- In general, the surface of the wood is not very smooth, so to sand about to paint, but must be careful not because of the pursuit of leveling, and the sand too far. Sand over the head will lead to corrosion and loss of anti-corrosion function.

- Q: What are the characteristics of antiseptic wood?

- 2 advantage: In fact, anti-corrosion wood in addition to anti-corrosion special, but also has anti-termite, fungi, anti-corrosion of the three basic functions. Antiseptic wood also has good permeability, resistance to loss of the characteristics of strong, but also inhibit the treatment of wood moisture content changes, reduce the degree of wood cracking.

Send your message to us

Anticorrosive ACQ Treated Fir Wood

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1x20' FCL m³

- Supply Capability:

- 20000M³ Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches