Magnesite Chrome Brick for Cement Rotary Kiln with Thermal Shock Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Magnesite-Chrome Brick

l CMAX magnesite-chrome brick is made of high quality magnesia and chrome ore.

l CMAX direct-bonded magnesite-chrome brick is made of low impurity chrome ore and high purity magnesia and sintered at high temperature over 1700℃.

l CMAX semi-rebonded and rebonded magnesite-chrome bricks are made partially or fully of synthetic fused clinkers. Magnesite-chrome brick are shaped under high pressure and sintered at very high temperature.

Feature of Magnesite-Chrome Brick

Good high-temperature performance

High thermal shock resistance

Strong slag resistance

High mechanical strength

Application of Magnesite-Chrome Brick

Cement rotary kiln

Non-ferrous furnace

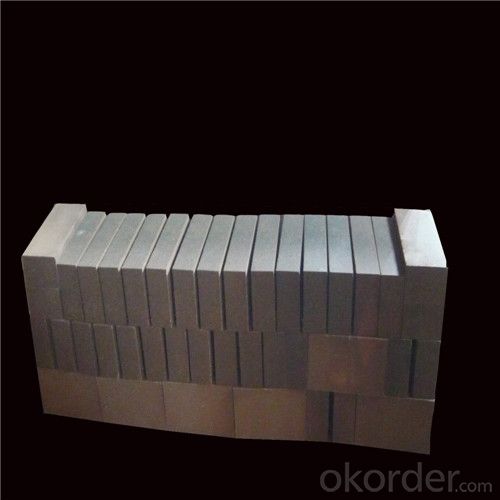

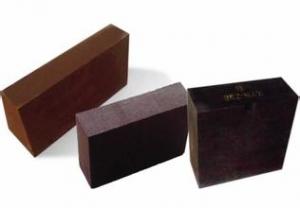

Image of Magnesite-Chrome Brick

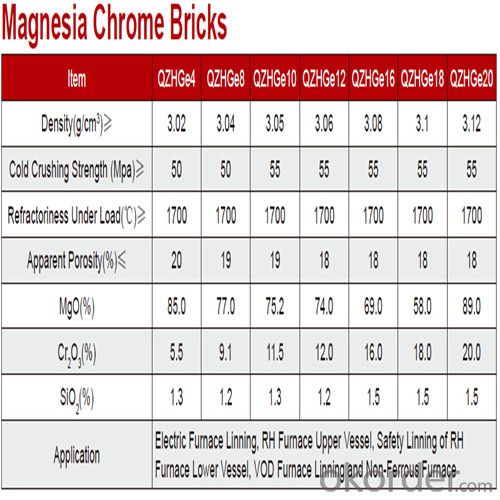

Technical Data of Magnesite-Chrome Brick

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals..

- Q: What are the differences between magnesium chrome bricks, such as direct bonding, re bonding, semi bonding, CO sintering and chemical bonding? Hope expert advice..

- The process of firing magnesia chrome bricks is roughly the same as that of magnesia bricks. In order to eliminate the brick during firing, due to MgO and Cr2O3, Al2O3

- Q: Process for producing magnesia chrome brick

- The fine powder compacts after calcination produced by magnesia - chrome ore grinding method, brick with magnesia coarse particles, are effective measures to eliminate the effect of loose. Compared with the common magnesia chrome brick, the magnesia chrome brick made by this method has lower porosity, higher compressive strength, higher softening temperature and higher flexural strength. Compacts with chrome magnesite powder, magnesia chrome brick by synthetic magnesia chrome sand made of high-temperature calcination, slag resistance and high temperature strength are better than other magnesite chrome brick.In addition, magnesite brick and electric arc furnace melting magnesium chromium material by direct casting (see Figure microstructure, color), fused magnesia chrome brick material produced by the process of melting particles combined with magnesia chrome brick etc..

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- I produce clay bricks, and my bricks stand at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q: How much is magnesium chrome brick a ton?

- The price of bricks in different places is not the same. The average price is about 3500 yuan

- Q: Magnesia chrome brick

- The fine powder compacts after calcination produced by magnesia - chrome ore grinding method, brick with magnesia coarse particles, are effective measures to eliminate the effect of loose. Compared with the common magnesia chrome brick, the magnesia chrome brick made by this method has lower porosity, higher compressive strength, higher softening temperature and higher flexural strength. Compacts with chrome magnesite powder, magnesia chrome brick by synthetic magnesia chrome sand made of high-temperature calcination, slag resistance and high temperature strength are better than other magnesite chrome brick.

- Q: How many kinds of refractory bricks are there?

- Magnesia chrome brick: Hang kiln, used for firing zone, the disadvantage is the poor thermal shock resistance, plus six Cr price is highly toxic, the production and use of the national magnesia chrome brick is gradually reduced, the brick production unit as soon as possible to find alternatives.

- Q: Magnesium chrome brick price?

- Magnesia brick factory with strong technology foundation as the basis, has developed more than 40 varieties of products, including building materials, non-ferrous metals, iron and steel and other fields, won the national high-tech products nearly a dozen, four patents, including magnesia spinel brick reached the world advanced levelFrom July 2006 to now won the high-tech enterprises in Liaoning province; National Standardization Management Committee issued the "adopting international standard product certificate" enterprises; in 2009 passed the ISO9001 quality management system certification; the famous brand products of Liaoning Province certificate certificate and certificate management, the reliable guarantee for the quality of products.

- Q: What is a half combination of magnesia chrome bricks?

- Opacifying particles as periclase spinel crystal structure, fully developed, as part of account of solution structure and matrix.

- Q: What is the difference between magnesia chrome brick and direct bonded magnesia chrome brick?

- The magnesium chromium brick with the direct bonded magnesia chrome brick is different: 1 with the purity of magnesia (raw materials) 2: the sintering temperature of common magnesia chrome brick sintering temperature at 1550 DEG ~1600 DEG, direct the magnesium chromium brick sintering temperature is over 1700 DEG C, because of its more than 1700 DEG C, magnesia chrome brick microstructure occurred change, and periclase chromium ore directly combined, so called direct bonded magnesia chrome brick

- Q: What are the main raw materials of magnesia chrome bricks?

- Magnesium alloys are alloys based on magnesium and other elements. Its characteristics are: small density (1.8g/cm3 magnesium alloy or so), high specific strength, high modulus of elasticity, good heat dissipation, good shock resistance, greater impact load capacity than aluminum alloy, good resistance to organic and alkaline corrosion. The main alloying elements are aluminum, zinc, manganese, cerium, thorium, and a small amount of zirconium or cadmium.

Send your message to us

Magnesite Chrome Brick for Cement Rotary Kiln with Thermal Shock Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords