Glass Wool Thermal Insulation Fiber Glass for Building Roofing and Wall 20kg/m3

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 400 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Wool are widely used in public, commercial and residential buildings as well as industrial plants, for applications such as roofing, external wall, partition wall and floating floor to provide fire protection, thermal insulation, acoustic control and condensation control.

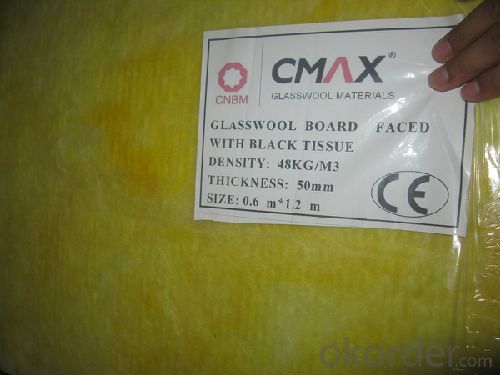

Item | Unit | Index |

Density | Kg/m3 | 10 - 48 |

Thickness | mm | 25-150 |

Width | mm | 1200 |

Length | mm | 5000-30000 |

● FEATURES

● Thermal Insulation ● Fire Safety ● Acoustic Control

● No Corrosion ● Environmental friendly ● Moisture Resistance

● Energy Conservation & Emissions Reduction

Standard Size

Blanket

Size: W*L (mm) 1200X10000 ( 10000- 30000)

Thickness (mm) 25, 30, 50, 60, 80,100

Technical Data

Item | Unit | Index |

Average Fiber Diameter | μm | About 7 |

Water Content | % | ≤1 |

Grade of Combustibility | Non-Combustible Grade A | |

Thermal Conductivity ( 25℃) | W/mK | 0.038- 0.045 |

Reshrinking Temp | ℃ | ≥300 |

Hydrophobic | % | ≥98 |

Moisture Rate | % | ≤5 |

Noise Resistant Coefficient (NRC) | About 0.75 | |

Slag Inclusion Content | % | ≤0.3 |

Material:

Double layers of aluminum foil reinforced with high tensile spring steel wire

Structure: High elastic wire, aluminum foil. A reinforcement model can be required.

Aluminum foil thickness: 0.035mm

Temperature range: -30°C~+140°C

Maxim Air Flow: 30m/s

- Q: What are the raw materials of centrifugal glass wool?

- Although I see it every day, but I really do not know about it, I only know that the main materials include glass and lime.

- Q: How about the sound insulation performance of glass wool felts?

- Fix the glass wool in the wall with pegs, then cover it with plywood, after laying up with wooden surface, nail the wood again.

- Q: Does curtain wall glass wool belong to thermal insulation wool?

- , the general it is mineral wool.

- Q: what's the price of high temperature resistance glass wool?

- the using temperature of alkali ultra-fine glass wool: -100 ~ 450 ℃. Ordinary glass wool: Intermediate starch bind products , -35 ~ 300 ℃. Intermediate fiber phenolic resin products, -35 ~ 350 ℃. glass wool asphalt bind product, -20 ~ 250 ℃. Price depends on how much K you need, that is, the number of density, the current ex-factory price for high temperature around 2500 one ton.

- Q: What is glass wool board.

- Glass wool is fibrillation by the fusion of the glass, adding binder to solidify the material to make the glass wool roll mat, while the glass wool fibre?diameter is contracted by the centrifugation. The difference is in the centrifugation techniques. the centrifugation techniques currently used most frequent is Saint-Gobain's Isover TEL centrifugation technique, which is the originator of glass wool products. At present the domestic glass wool market is gradually expanding, and enterprise Dacheng Quanhe Chemical Co., Ltd. makes a significant contribution to promote the use of glass wool.

- Q: What are the advantages and disadvantages of glass fiber insulation cotton?

- Glass fiber sound insulation cotton advantages and disadvantages are not waterproof, rain or after washing with water in the process, resulting in a substantial increase in dead load, accelerate landing, it is difficult to water evaporation in a short time, and wet part of the body could easily lead to corrosion. In addition, there is no environmental friendly problems which is well known, and it is also a strong carcinogen.

- Q: Whether the rock wool is belong to the glass wool product or not.

- Rockwool certainly do not belong to the glass wool products, rock wool is rock wool, glass wool is glass wool.

- Q: How is the thermal insulation property of glass cotton?

- Glass wool is better, but it is also more expensive.

- Q: Does glass wool equals to rock wool?

- It has advantages of good sound-absorbing , welding and thermal insulation performance, small bulk density, chemical stability, corrosion resistance, and belongs to glass in terms of chemical composition. It is an man-made inorganic fiber, cotton-like material. Glass wool belongs to glass fiber with low thermal conductivity which is a mineral wool. Rock wool is also known as asbestos. Glass wool fiberizes molten glass.

- Q: What is the highest temperature that the fireproof glass?cotton can resist?

- The highest temperature that fireproof glass wool can resist is 200 degrees, so it can be used for a long time. It is difficult to estimate the specific time. Generally, it can endure three months if it is used for eight hours every day.

Send your message to us

Glass Wool Thermal Insulation Fiber Glass for Building Roofing and Wall 20kg/m3

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 400 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches