Xps Foam Board Philippines - Thermal Extruded Polystyrene Board/XPS Insulation Foam Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | XPS Boards,Heat Insulation Materials | Place of Origin: | Brand Name: | ||

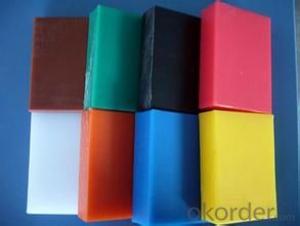

| Model Number: | WL-XPS | Thickness: | 20-50mm | color: | Blue, Pink,Green, Grey etc. |

| Density: | 32-35kg/m3 | Width: | 600-1200mm | Length: | 1200-10000mm |

| Compressive Strength: | 280-400kpa | Surface: | Smooth and Rough |

Packaging & Delivery

| Packaging Detail: | plastic packaging or according to client's request |

| Delivery Detail: | 10-15days |

Specifications

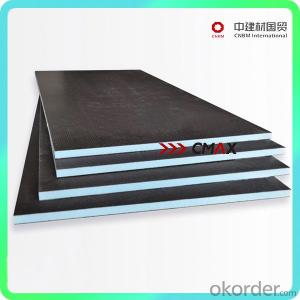

Thermal extruded polystyrene board/XPS insulation foam panel

1.Great anti-corrosion

2.Water-resistance

3.Fire prevention

Thermal extruded polystyrene board/XPS insulation foam panel

² Description:

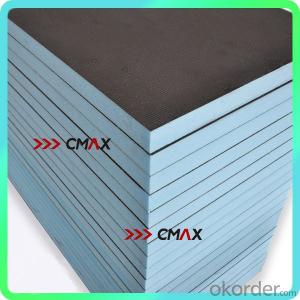

1. XPS is an extruded polystyrene insulation manufactured through a plastic extrusion process. The

resulting boards are almost 100% closed cell, strong, highly moisture resistant and easy to cut and shape.

2. XPS is particularly indicated for places where a high mechanic resistance is required. Its resistance

to water and compression make it the ideal insulation solution for extreme conditions. Moreover, it is

very easy to install and offers a high performance thermal insulation for your building.

3. XPS foam board widely used in wall insulation, low-temperature storage facilities, parking platform, the airport runway,construction of concrete roof and the structure of roof, highways and other areas of misture-proof inexpensive decoration industry material.

Thermal extruded polystyrene board/XPS insulation foam panel

Length(mm) | Width(mm) | Thickness(mm) | Density(kg/m3) |

1200-10000 | 600-1200 | 20-50 | 32-35 |

Compressive Strength(kpa) | color | Surface | |

280-400 | Blue,Pink,Green,Grey etc. | Smooth and Rough | |

- Q: 25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- Sandwich board is made of color coated board, stainless steel and other materials as the surface of the composite board, because of its unique dust, anti-static, anti-bacterial effect, is widely used in electronics, pharmaceuticals, food, biological, aerospace, precision Equipment manufacturing and scientific research on the indoor environment demanding clean engineering areas

- Q: What is the difference between extruded polystyrene board and XPS insulation board?

- Is a normal phenomenon, frost in the frost when the frost, and a temperature probe.

- Q: Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Metal hose is an important connection in engineering technology, from the corrugated flexible tube, mesh sets and joints combined. China in 1993 issued a national standard "corrugated metal hose general technical conditions" (GB / T-93). Metal hoses are made of austenitic stainless steel or according to the material required by the user. It has excellent softness, corrosion resistance, high temperature resistance (-235 ℃ ~ + 450 ℃), High pressure (up to 32MPa), in the pipeline can be connected in any direction for temperature compensation and absorption of vibration, reduce noise, change the direction of media transmission, to eliminate the pipe or between the pipe and mechanical displacement between equipment, Lan metal corrugated hose for a displacement, vibration of the various pumps, valves and other flexible joints is particularly applicable. Metal hoses use two kinds of bellows, one is a spiral corrugated tube; the other is a ring bellows. Spiral bellows The spiral bellows is a tubular shell with a corrugated spiral and has a helix angle between adjacent two corrugations. All corrugations can be connected by a helix. Ring bellows Corrugated tube is corrugated closed ring shaped tubular shell, wave and wave from the ring ripple in series. The ring bellows is machined from a seamless pipe or welded pipe. By the processing mode, compared with the spiral corrugated pipe, the length of a single tube is usually shorter. The advantage of the ring bellows is good elasticity and small rigidity. If you need to provide detailed advice, please call 0317-, Xinlong bellows will be happy to serve you.

- Q: I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- 25 thick extruded polystyrene plastic insulation board 35kg / m3

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- The best bamboo pole, or plastic, aluminum alloy, then there is no child at home can have a child, then it is dangerous to fall easily hit people

- Q: Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- Use the wall connection, set the location, the number of construction sites in accordance with the development of specific programs to determine. But also must meet the "construction of fastener type steel pipe scaffolding safety technical specifications JGJ130-20 lack of reminders of the United States and the United States and the United States and the United States and the United States and the United States, Note: . different erection mode, different height, the vertical spacing, horizontal spacing, each wall with a specific coverage area requirements. . pay attention to the standard is JGJ130-. do not use JGJ130-2002 old standard, the old and new standards on the wall with a little different provisions.

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- More than 24 meters need to use cantilevered scaffolding, and the spacing of not more than 20 meters

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- The key depends on your choice of waterproof construction and product quality, we recommend you choose Dongfang Yuhong waterproof products and standardized construction team, the East Rainbow is the best quality waterproof listed enterprises RPUF-371 sprayed foam polyurethane waterproof insulation integrated system " Rainbow "spray foam polyurethane waterproof insulation integrated system is composed of rigid foam polyurethane foam waterproof insulation integrated material and the protection of the surface layer composition

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Single-row fastener type steel pipe scaffold for decoration works in the construction of small horizontal bar spacing should be the number of mm.........................................................

- Q: What is the difference between an extruded board and an XPS extruded board?

- 1. Civilized construction program 2. Safe construction program 3. Template construction program 4. Scaffolding construction program 5. Sambo four construction program 6. Temporary electricity construction program 7. High operating construction program 8. Tower crane construction plan 9. Multi-tower operation anti-collision construction program 10. Emergency emergency plans 11. Winter rainy season construction program 12. Significant hazard assessment measures 13. Construction organization design 14. Building energy conservation program 15. Basket construction program 16. Tower crane hoisting program

Send your message to us

Xps Foam Board Philippines - Thermal Extruded Polystyrene Board/XPS Insulation Foam Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords