The Coke Breeze of Size is 0 – 10 mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of The Coke Breeze of Size is 0 – 10 mm Description:

Coke is made by high temperature metallurgical coke for blast furnace smelting, casting and gasification. Occurring in the process of coking after recovery and purification of coke oven gas is a high calorific value of fuel, is an important industrial raw material in organic synthesis.

Coke is mainly used for blast furnace ironmaking and used for copper, lead, zinc, titanium, antimony, mercury and other non-ferrous metal smelting of blast furnace, reducing agent, compound and the function of stock column frame.

Blast furnace with Coke instead of charcoal, which laid a foundation for the large-scale of modern blast furnace, is a major milestone in the history of metallurgy.

2. Main Features of The Coke Breeze of Size is 0 – 10 mm:

• Quality assurance

• Mutual benefit

• Preferential price

• Various choice

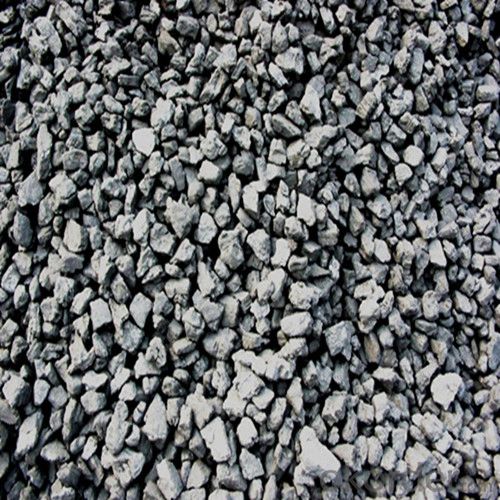

3. The Coke Breeze of Size is 0 – 10 mm Images:

4. The Coke Breeze of Size is 0 – 10 mm Specification:

Parameters | Ash(DB) | Moisture (ARB)

| Volatile Matter (DB) | Fix Carbon (DB) | Size 0-10mm

|

+10mm |

Guarantee | 12.5%max | 15%max | 1.5%max | 83%min | 90%min | 5%max |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2) What are coke's main physical properties?

The average heat capacity is 0.808 kj/(KGK) (100 ℃), 1.465 kj/(KGK) (1000 ℃)

Thermal conductivity is 2.64 kj/(MHK) (room temperature), 6.91 kj/(MHK) (900 ℃);

Ignition temperature (air) is 450-650 ℃.

3) How about your company?

Our company began to export coke when China cancelled 40% of coke export tariffs and quotas on January 1, 2013. We export many kinds of coke, such as CSR60 % and CSR 62% metallurgical coke (met coke), the NUT coke of 20 to 50 mm, coke breeze of 3 to 6 mm, and so on.

- Q: What is the concept, relationship and difference between coke and coke? The main difference and contact, thank you

- Formed coke is a product obtained through several steps:(1) environmental protection continuous high efficiency carbonization furnace(2) the use of anthracite powder to produce plastic molding coke and supporting technology(3) a new type of environmentally friendly carbonization carbonization furnace without three wastes discharge.(4) hydraulic press

- Q: Said the details can add points ah

- 50 kilograms of size greater than 60 mm coke coke samples, in meters Qom in the drum at 50 rpm speed of 100 revolutions (4 minutes), with the aperture is 40 mm (25 mm) sieve screening, measuring more than 40 mm (25 mm) and the weight percentage of the coke, the total weight of the coke drum, denoted as M40 (or M25).

- Q: China's coke iron smelting began in what time?

- Han also invented the "fried steel law", that is, the use of pig iron "fried" mature iron or steel of the new process, the product is called steel. At the same time, the rise of "100 steelmaking" technology. The Eastern Han Dynasty (AD 25 ~ 220), when the emperor of the Ming Dynasty, invented the hydraulic blast furnace, that is, "water discharge". The invention of ancient water row in China, about 1100 years earlier than europe. After the Han Dynasty, the method of steel. "Qi Shu Qi, even referred to as" places "big steel", later known as the filling steel, also known as steel group. This is another important achievement of the ancient steelmaking technology in china. According to the "Encyclopedia of" records: Chinese is the earliest use of coal iron country, the Han Dynasty have been tried, song and Yuan dynasties have been popularized. To the Ming Dynasty (AD 1368 ~ 1644) has been able to use coke smelting pig iron.

- Q: Who knows the proportion of pig iron and coke used in Cupola

- There is doubt: the export rate is lower than the standard exception.4, blank blank processing: according to customer requirements of different direct sales, some need to continue processing after the sale, the ordinary rough machined after a blank rate of about more than 70%, about 30% (excluding scrap scrap), dryer enterprises after after machining yield is about 25% ~ 30% (including waste scrap and iron, basically use recycled material, material waste accounted for ratio of 30% ~ 40%). To 1.5M x 2M cylinder, for example, rough weight of about 5.8 tons ~ ~ 6 tons (standard cylinder, including the cylinder head) cylinder head rough weight of about 1.7 tons ~ ~ 1.8 tons, cylinder weight of about about 4.2 tons. After processing, the cylinder head weighs about 0.5 tons to 0.6 tons, accounting for the proportion of about 65% to 70% head (excluding scrap, scrap accounted for about 10%, blank cylinder head and iron) accounted for about 30% ~ 35% blank cylinder head, accounted for the proportion is about 40% recycled waste, scrap iron accounted for under foot material proportion 60%, enterprises can not return direct sales (currently, only production enterprises can use recycled scrap iron). Total iron blank ratio is about 15% ~ 18%.

- Q: Why is coke used in blast furnace steelmaking?Why not use coal?

- The reason of coke used in blast furnace steelmaking:Coke is the product after the desulfurization of coal, because the removal of sulfur in coal, coal tar and other harmful substances, no longer in the process of steelmaking, the impact on the quality of steel, the formation of unnecessary ingredients.

- Q: I now do a good job in the coke network editor, I would like to know more about coke

- Direct reduction in the blast furnace in the area above 850 degrees celsius. Because the CO2 generated at high temperature immediately reacts with the carbon in coke to form CO, it can be considered that the carbon in coke is directly involved in the reduction process:CO is used as reducing agent, either indirect or direct reduction. In order to continue to add CO, requires a certain degree of reactivity of coke.

- Q: How many degrees of coke ignition temperature can ignite coke

- The average specific heat capacity is 0.808kj/ (KGK) (100 DEG C), 1.465kj/ (KGK) (1000 DEG C);The thermal conductivity is 2.64kj/ (MHK) (room temperature), 6.91kg/ (MHK) (900 DEG C);Ignition temperature (450-650) in air;

- Q: What are the quality indicators of coke

- Coke is a solid product of high temperature carbonization, the main component is carbon, is a crack and irregular pore structure (or porous). The number of cracks has a direct impact on the strength and crushing strength of the coke, the index is generally measured in terms of crack degree (the number of cracks in the unit volume coke). The index of pore structure is mainly expressed by the porosity rate (the percentage of the total volume of coke), which affects the reactivity and strength of coke.

- Q: Effect of coke powder ratio on the index

- Quality index of cokeHigh temperature carbonization coke is the solid product, its main ingredient is carbon, the pore structure of spores (or pore porous) with crack and irregular crack. Have a direct impact on how much strength and crushing strength of coke, the index of crack usually (crack length per unit volume of coke in the index) to measure indicator. Pore structure is mainly used for measuring the porosity of spores (pore volume percentage of the total volume of coke) said that it affects the reactivity and strength of coke. The coke used for different purposes, the porosity index requirements change, but it usually requires 40 to 45% metallurgical coke porosity, casting requirements of 35 to 40%, the export of coke need to crack about 30%. coke with high and low levels of porosity, the use of coking coal has a direct relationship, such as gas refining is mainly coke, crack, high porosity, low strength; as in coking coal Break the coke refining base of small, low porosity and high strength. The strength of coke is usually the crushing strength and abrasion resistance of two indexes to represent the strength of coke can be broken. No cracks or defects and M40 values along the fault reference external shock resistance structure; wear strength of coke coke refers to the ability to form glass the surface resistance to foreign friction and no fragments or powder, expressed as the value of M10. The degree of M40 crack coke compressive strength affect the value, value of pore structure of coke impact wear resistance of M10 spores. The determination of M40 M10 and a lot of value, many German migon drum test our method.

- Q: What is the effect of coke moisture on the blast furnace?

- The influence of coke moisture on blast furnace can be divided into two parts:

Send your message to us

The Coke Breeze of Size is 0 – 10 mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords